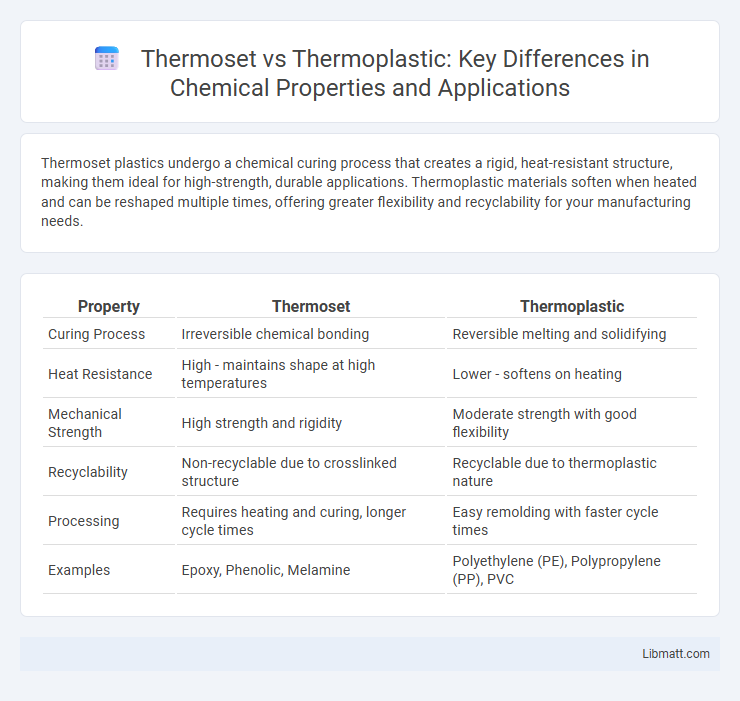

Thermoset plastics undergo a chemical curing process that creates a rigid, heat-resistant structure, making them ideal for high-strength, durable applications. Thermoplastic materials soften when heated and can be reshaped multiple times, offering greater flexibility and recyclability for your manufacturing needs.

Table of Comparison

| Property | Thermoset | Thermoplastic |

|---|---|---|

| Curing Process | Irreversible chemical bonding | Reversible melting and solidifying |

| Heat Resistance | High - maintains shape at high temperatures | Lower - softens on heating |

| Mechanical Strength | High strength and rigidity | Moderate strength with good flexibility |

| Recyclability | Non-recyclable due to crosslinked structure | Recyclable due to thermoplastic nature |

| Processing | Requires heating and curing, longer cycle times | Easy remolding with faster cycle times |

| Examples | Epoxy, Phenolic, Melamine | Polyethylene (PE), Polypropylene (PP), PVC |

Introduction to Thermoset and Thermoplastic Polymers

Thermoset polymers are materials that undergo an irreversible curing process, forming a rigid, three-dimensional network highly resistant to heat and chemical degradation. Thermoplastics consist of linear or branched polymer chains that soften upon heating and solidify when cooled, allowing for repeated reshaping and recycling. Key examples include epoxy and phenolic resins for thermosets, and polyethylene and polypropylene for thermoplastics, each offering distinct mechanical and thermal properties suited for various industrial applications.

Chemical Structure Differences

Thermosets possess a heavily cross-linked polymer network formed through irreversible chemical bonds, providing high thermal stability and rigidity. Thermoplastics consist of linear or branched polymer chains without cross-linking, allowing them to soften upon heating and be reshaped multiple times. The chemical structure differences result in thermosets offering superior mechanical strength and chemical resistance, while thermoplastics provide enhanced flexibility and recyclability.

Manufacturing Processes Comparison

Thermoset manufacturing involves processes like molding, curing, and heat treatment, resulting in a rigid, heat-resistant product that cannot be reshaped once set. Thermoplastics are processed through melting and molding techniques such as injection molding and extrusion, allowing the material to be repeatedly heated and reshaped. Understanding these differences in manufacturing processes helps you select the appropriate material based on flexibility, durability, and production efficiency requirements.

Mechanical and Thermal Properties

Thermosets exhibit superior thermal stability and higher mechanical strength due to their cross-linked polymer structure, making them ideal for high-temperature applications. Thermoplastics offer greater flexibility and impact resistance, as their linear polymer chains allow for easy reshaping and reheating. Understanding these mechanical and thermal property differences helps you select the right material for durability and performance in your specific application.

Applications in Various Industries

Thermoset materials are widely used in automotive, aerospace, and electronics industries for high-strength, heat-resistant components such as engine parts, electrical insulators, and composite panels. Thermoplastics dominate packaging, consumer goods, and medical device manufacturing due to their recyclability, flexibility, and ease of molding into complex shapes. Each polymer type offers distinct advantages, with thermosets excelling in structural applications and thermoplastics providing versatility in mass production and design adaptability.

Advantages of Thermoset Polymers

Thermoset polymers offer superior thermal stability and chemical resistance, making them ideal for high-temperature applications and harsh environments. Their cross-linked molecular structure provides exceptional mechanical strength and dimensional stability, reducing deformation under stress. These properties make thermosets preferred materials in automotive, aerospace, and electrical insulation industries where durability and reliability are critical.

Advantages of Thermoplastic Polymers

Thermoplastic polymers offer significant advantages, including excellent recyclability due to their ability to be melted and reshaped multiple times without chemical alteration. They exhibit high impact resistance and flexibility, making them ideal for applications requiring durability and toughness. Moreover, thermoplastics allow for efficient manufacturing processes such as injection molding, reducing production costs and enabling complex geometries.

Limitations and Challenges

Thermosets are limited by their irreversible curing process, which prevents reshaping or recycling, leading to environmental concerns and higher disposal costs. Thermoplastics face challenges such as lower thermal resistance and mechanical strength compared to thermosets, restricting their use in high-temperature or load-bearing applications. Processing thermosets requires precise control of curing conditions to avoid defects, while thermoplastics are prone to warping and shrinkage during cooling, affecting dimensional stability.

Environmental Impact and Recycling

Thermosets create strong, durable products through irreversible curing, making their recycling challenging and often resulting in landfill accumulation, which raises environmental concerns. Thermoplastics, on the other hand, can be melted and reshaped multiple times, enabling easier recycling and reduced environmental footprint. Choosing thermoplastics for your applications supports sustainable waste management and lowers ecological impact.

Choosing the Right Material for Your Application

Selecting between thermoset and thermoplastic materials depends on application requirements such as thermal stability, mechanical strength, and chemical resistance. Thermosets offer superior heat resistance and structural rigidity, making them ideal for electrical components and automotive parts subjected to high temperatures. Thermoplastics provide flexibility, recyclability, and ease of molding, favored in consumer goods and packaging where impact resistance and cost-efficiency are critical.

Thermoset vs thermoplastic Infographic

libmatt.com

libmatt.com