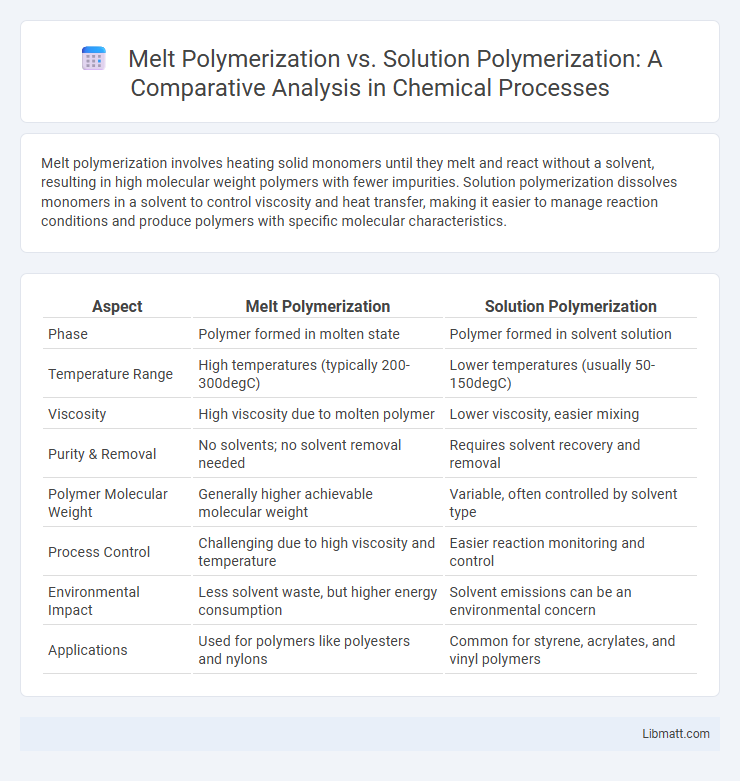

Melt polymerization involves heating solid monomers until they melt and react without a solvent, resulting in high molecular weight polymers with fewer impurities. Solution polymerization dissolves monomers in a solvent to control viscosity and heat transfer, making it easier to manage reaction conditions and produce polymers with specific molecular characteristics.

Table of Comparison

| Aspect | Melt Polymerization | Solution Polymerization |

|---|---|---|

| Phase | Polymer formed in molten state | Polymer formed in solvent solution |

| Temperature Range | High temperatures (typically 200-300degC) | Lower temperatures (usually 50-150degC) |

| Viscosity | High viscosity due to molten polymer | Lower viscosity, easier mixing |

| Purity & Removal | No solvents; no solvent removal needed | Requires solvent recovery and removal |

| Polymer Molecular Weight | Generally higher achievable molecular weight | Variable, often controlled by solvent type |

| Process Control | Challenging due to high viscosity and temperature | Easier reaction monitoring and control |

| Environmental Impact | Less solvent waste, but higher energy consumption | Solvent emissions can be an environmental concern |

| Applications | Used for polymers like polyesters and nylons | Common for styrene, acrylates, and vinyl polymers |

Introduction to Polymerization Techniques

Melt polymerization involves heating monomers until they melt and react without solvents, producing high-purity polymers like nylon and PET with efficient heat transfer and high reaction rates. Solution polymerization dissolves monomers in a solvent, allowing better temperature control and easier handling of reaction viscosity, widely used for polymers such as polyacrylates and styrenics. Each technique offers distinct advantages for controlling molecular weight, polymer architecture, and processing conditions, impacting industrial applications and material properties.

Overview of Melt Polymerization

Melt polymerization involves the polymerization of monomers in their molten state without solvents, resulting in high-purity polymers with fewer by-products. It offers advantages such as environmentally friendly processing and efficient heat transfer, making it suitable for producing polymers like polyesters and polyamides. Your choice of polymerization method can impact polymer quality, processing time, and scalability.

Fundamentals of Solution Polymerization

Solution polymerization occurs when monomers and initiators are dissolved in a solvent, creating a homogeneous reaction medium that facilitates heat dissipation and molecular mobility. This process enables control over polymer molecular weight and structure while maintaining reaction temperatures below the polymer's melting point, preventing degradation. Your choice between melt and solution polymerization depends on factors such as polymer solubility, desired molecular characteristics, and processing conditions.

Key Process Differences

Melt polymerization involves heating monomers to their melting point to initiate polymerization without a solvent, resulting in a highly viscous melt where polymers form directly. Solution polymerization dissolves monomers in a solvent, allowing polymerization to occur in a liquid phase at lower temperatures, which facilitates better heat dissipation and easier handling of viscosity. Your choice between these methods affects reaction control, product purity, and processing conditions.

Reactors and Equipment Used

Melt polymerization primarily utilizes batch or continuous stirred tank reactors designed to handle high viscosity molten polymers without solvents, often equipped with strong agitators and heating systems to maintain the required temperature. Solution polymerization employs reactors such as continuous stirred tank reactors or loop reactors that operate at lower viscosities due to the presence of solvents, facilitating heat removal and better mixing. Your choice of polymerization method impacts the reactor design and auxiliary equipment, including solvent recovery units for solution polymerization or specialized extruders for melt polymerization.

Advantages of Melt Polymerization

Melt polymerization offers significant advantages such as the elimination of solvents, resulting in an environmentally friendly and cost-effective process with fewer purification steps. This method enables higher molecular weight polymers due to the absence of solvent interference and allows precise control over reaction conditions like temperature and viscosity. The direct melt state also facilitates easier recycling and reduces potential contamination, making melt polymerization highly efficient for producing high-purity polymers.

Benefits of Solution Polymerization

Solution polymerization offers superior heat dissipation due to the solvent medium, reducing the risk of uncontrolled exothermic reactions and ensuring better temperature control. It facilitates higher molecular weight polymers with narrower molecular weight distribution, enhancing polymer uniformity and performance. The liquid environment also simplifies processing and purification, allowing easier removal of residual monomers and byproducts.

Environmental and Safety Considerations

Melt polymerization eliminates the use of solvents, significantly reducing volatile organic compound (VOC) emissions and minimizing hazardous waste, making it environmentally preferable to solution polymerization. Solution polymerization, involving organic solvents, poses higher risks of toxicity, flammability, and environmental contamination, requiring stringent handling and disposal measures. The reduced solvent exposure in melt polymerization enhances worker safety by lowering inhalation hazards and fire risks in industrial settings.

Industrial Applications and Product Examples

Melt polymerization is predominantly used in producing high-performance polymers such as polyethylene terephthalate (PET) and nylon, commonly found in fibers, packaging films, and engineering plastics. Solution polymerization enables better heat control and is widely applied in manufacturing specialty polymers like polyacrylonitrile for carbon fiber precursors and various styrene-based plastics used in adhesives and coatings. Industrial applications favor melt polymerization for bulk polymer production due to cost efficiency, while solution polymerization suits applications requiring precise molecular weight control and polymer architecture.

Comparative Analysis: Choosing the Right Method

Melt polymerization offers a solvent-free process ideal for producing high-purity polymers with minimal environmental impact, while solution polymerization provides better control over molecular weight and polymer architecture through the use of various solvents. Your choice depends on factors like polymer type, desired molecular characteristics, and processing conditions; melt polymerization suits bulkier, thermally stable monomers, whereas solution polymerization is preferred for sensitive or heat-labile compounds. Evaluating the trade-offs in reaction control, scalability, and product properties guides selecting the most efficient polymerization method.

Melt polymerization vs solution polymerization Infographic

libmatt.com

libmatt.com