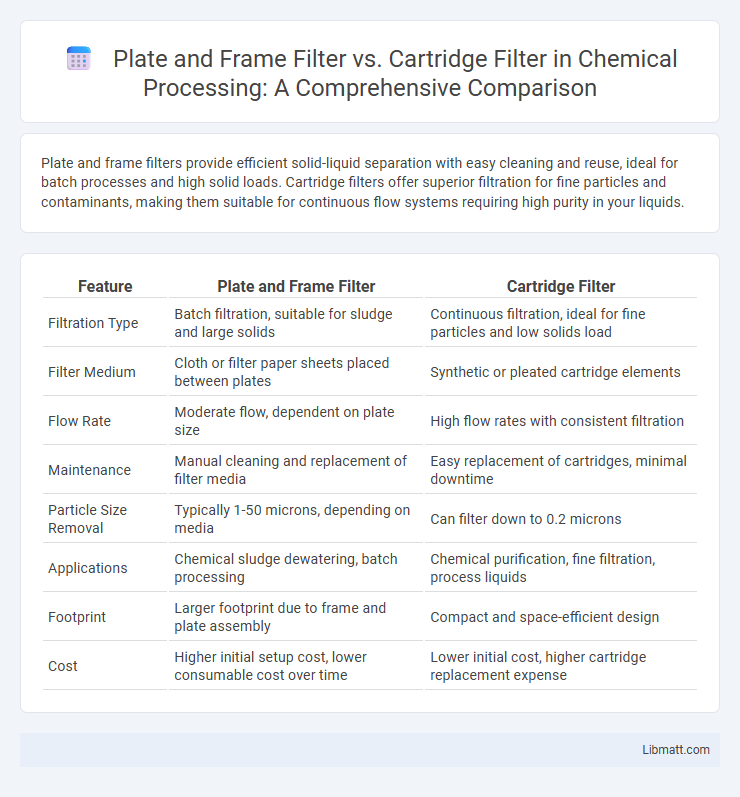

Plate and frame filters provide efficient solid-liquid separation with easy cleaning and reuse, ideal for batch processes and high solid loads. Cartridge filters offer superior filtration for fine particles and contaminants, making them suitable for continuous flow systems requiring high purity in your liquids.

Table of Comparison

| Feature | Plate and Frame Filter | Cartridge Filter |

|---|---|---|

| Filtration Type | Batch filtration, suitable for sludge and large solids | Continuous filtration, ideal for fine particles and low solids load |

| Filter Medium | Cloth or filter paper sheets placed between plates | Synthetic or pleated cartridge elements |

| Flow Rate | Moderate flow, dependent on plate size | High flow rates with consistent filtration |

| Maintenance | Manual cleaning and replacement of filter media | Easy replacement of cartridges, minimal downtime |

| Particle Size Removal | Typically 1-50 microns, depending on media | Can filter down to 0.2 microns |

| Applications | Chemical sludge dewatering, batch processing | Chemical purification, fine filtration, process liquids |

| Footprint | Larger footprint due to frame and plate assembly | Compact and space-efficient design |

| Cost | Higher initial setup cost, lower consumable cost over time | Lower initial cost, higher cartridge replacement expense |

Introduction to Plate and Frame vs Cartridge Filters

Plate and frame filters use a series of plates and filter cloths to separate solids from liquids through pressure, offering easy access for cleaning and maintenance. Cartridge filters rely on replaceable pleated cartridges that provide high surface area for filtration, ideal for fine particle removal and compact systems. Your choice between these two depends on the application's flow rate, particle size, and maintenance preferences.

How Plate and Frame Filters Work

Plate and frame filters operate by passing liquids through a series of filter plates and frames arranged alternately, where filter cloths capture solid particles and impurities. The liquid flows under pressure through the filter media, leaving the solids trapped in the cloth while the clarified liquid exits the system. This design allows easy removal and cleaning of the filter plates, making it suitable for processes requiring frequent maintenance or batch filtration.

How Cartridge Filters Operate

Cartridge filters operate by forcing fluid through a cylindrical, pleated filter media that captures contaminants on the surface as the fluid flows from the outside inward. The design provides high filtration efficiency with a large surface area, allowing for longer service life and lower pressure drops compared to plate and frame filters. Your filtration system benefits from easy cartridge replacement and maintenance, making cartridge filters ideal for applications requiring consistent, reliable particle removal.

Key Differences: Plate and Frame vs Cartridge Filters

Plate and frame filters utilize a series of plates and filter cloths to separate solids from liquids, ideal for batch filtration with easy cleaning and maintenance. Cartridge filters employ cylindrical cartridges that provide high surface area, offering continuous filtration with fine particle retention suitable for automated systems. Key differences include the plate and frame's suitability for viscous or slurry materials versus the cartridge filter's efficiency in filtering liquids with low solids content and their respective maintenance and operational costs.

Filtration Efficiency Comparison

Plate and frame filters offer high filtration efficiency for coarse and medium particle removal, typically achieving filtration down to 50 microns or larger, making them suitable for industrial applications with heavy contaminant loads. Cartridge filters excel in fine filtration, capturing particles as small as 1 micron or less, ensuring superior clarity and protection for sensitive processes or equipment. You should choose a cartridge filter when precision filtration and high contaminant retention are critical, while plate and frame filters perform better in handling large volumes and heavier solids.

Maintenance and Cleaning Requirements

Plate and frame filters demand frequent disassembly for manual cleaning and gasket replacement, making maintenance labor-intensive and time-consuming. Cartridge filters feature replaceable or cleanable filter elements that simplify upkeep, reducing downtime and labor costs. Effective maintenance schedules and proper cleaning protocols extend filter life and ensure optimal filtration efficiency in both systems.

Cost Analysis: Initial and Long-term

Plate and frame filters generally incur lower initial costs due to simpler construction and easier maintenance, making them budget-friendly for smaller operations. Cartridge filters often have higher upfront expenses but provide extended longevity and reduced downtime, resulting in lower long-term operational costs. Evaluating total cost of ownership requires considering replacement frequency, cleaning processes, and energy consumption differences between the two filter types.

Applications and Industry Suitability

Plate and frame filters excel in heavy-duty industries such as chemical processing, wastewater treatment, and food and beverage production due to their capacity for handling large volumes and high solids content. Cartridge filters are preferred in pharmaceutical, electronics, and beverage industries where filtration precision, sterility, and ease of replacement are critical. The choice between plate and frame and cartridge filters largely depends on specific operational requirements like flow rates, particle size removal, and ease of maintenance within respective industrial applications.

Advantages and Disadvantages of Each Filter

Plate and frame filters offer high filtration efficiency and ease of maintenance due to their modular design, but they require more space and manual labor for cleaning. Cartridge filters provide compact size and automatic operation with consistent performance, yet they often have higher replacement costs and limited filter media options. Your choice depends on application needs, balancing factors like maintenance frequency, space availability, and cost-efficiency.

Choosing the Right Filter for Your Needs

Plate and frame filters excel in applications requiring high solids handling and easy maintenance, making them ideal for industries like food processing and wastewater treatment. Cartridge filters provide superior filtration efficiency with finer micron ratings, best suited for liquid clarification and pharmaceutical production. Selecting the right filter depends on factors such as flow rate, particle size, ease of cleaning, and budget constraints.

Plate and frame filter vs cartridge filter Infographic

libmatt.com

libmatt.com