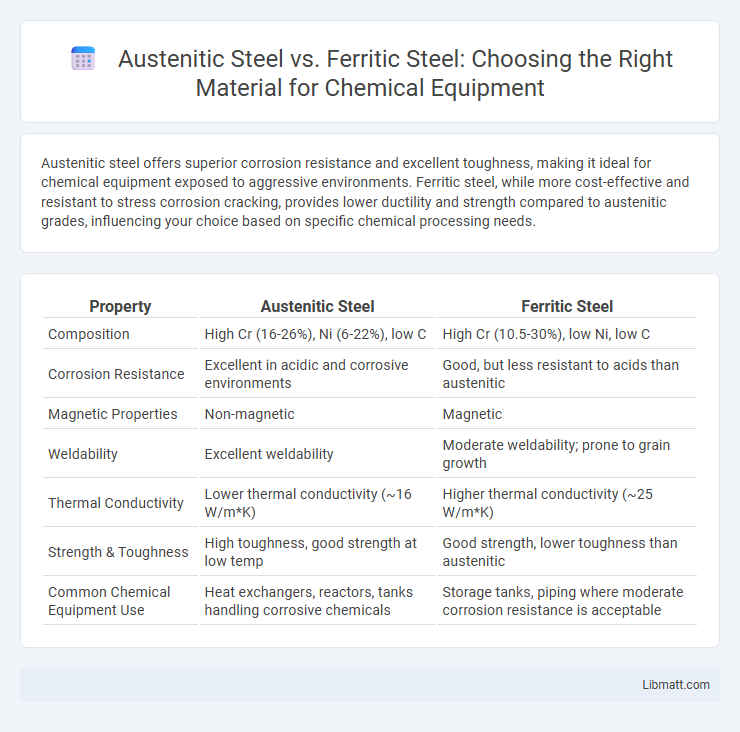

Austenitic steel offers superior corrosion resistance and excellent toughness, making it ideal for chemical equipment exposed to aggressive environments. Ferritic steel, while more cost-effective and resistant to stress corrosion cracking, provides lower ductility and strength compared to austenitic grades, influencing your choice based on specific chemical processing needs.

Table of Comparison

| Property | Austenitic Steel | Ferritic Steel |

|---|---|---|

| Composition | High Cr (16-26%), Ni (6-22%), low C | High Cr (10.5-30%), low Ni, low C |

| Corrosion Resistance | Excellent in acidic and corrosive environments | Good, but less resistant to acids than austenitic |

| Magnetic Properties | Non-magnetic | Magnetic |

| Weldability | Excellent weldability | Moderate weldability; prone to grain growth |

| Thermal Conductivity | Lower thermal conductivity (~16 W/m*K) | Higher thermal conductivity (~25 W/m*K) |

| Strength & Toughness | High toughness, good strength at low temp | Good strength, lower toughness than austenitic |

| Common Chemical Equipment Use | Heat exchangers, reactors, tanks handling corrosive chemicals | Storage tanks, piping where moderate corrosion resistance is acceptable |

Introduction to Austenitic and Ferritic Steels in Chemical Equipment

Austenitic steel, characterized by high chromium and nickel content, provides excellent corrosion resistance and superior strength at elevated temperatures, making it ideal for chemical equipment exposed to aggressive environments. Ferritic steel, containing higher chromium but low nickel, offers good resistance to stress corrosion cracking and thermal fatigue, often used in equipment requiring magnetic properties and moderate corrosion resistance. Your choice between these steels depends on factors like chemical exposure, temperature range, and mechanical demands in the chemical processing application.

Chemical Composition Differences

Austenitic steel contains high levels of chromium (typically 16-26%) and nickel (6-22%), providing excellent corrosion resistance and non-magnetic properties, making it ideal for chemical equipment exposed to aggressive environments. Ferritic steel has lower chromium content (10.5-27%) and negligible nickel, resulting in magnetic behavior and moderate corrosion resistance, suitable for less severe chemical applications. Your choice between these steels depends on the specific chemical composition requirements for durability and resistance in the equipment's operational environment.

Microstructural Characteristics

Austenitic steel in chemical equipment exhibits a face-centered cubic (FCC) microstructure, providing excellent toughness and corrosion resistance, especially in high-temperature and aggressive environments. Ferritic steel features a body-centered cubic (BCC) microstructure, offering superior resistance to stress corrosion cracking but lower ductility compared to austenitic grades. The FCC structure of austenitic steel allows for higher chromium and nickel content, enhancing its chemical resistance, while the BCC structure of ferritic steel limits alloying elements but improves thermal conductivity and resistance to magnetic fields.

Corrosion Resistance Comparison

Austenitic steel offers superior corrosion resistance in chemical equipment due to its high chromium and nickel content, which forms a stable passive layer protecting against aggressive environments. Ferritic steel, with lower nickel and higher chromium, provides good resistance but is more prone to stress corrosion cracking and less effective in acidic or chloride-rich conditions. For your chemical processing needs, selecting austenitic steel ensures enhanced durability and longevity in corrosive service applications.

Mechanical Properties Analysis

Austenitic steel exhibits superior toughness and ductility compared to ferritic steel, making it ideal for chemical equipment exposed to dynamic stresses and thermal cycling. Ferritic steel offers higher resistance to stress corrosion cracking but lower tensile strength and elongation, which can limit its use under high mechanical loads. Your choice should consider the specific mechanical demands of the chemical process to optimize performance and durability.

Weldability and Fabrication Aspects

Austenitic steel offers superior weldability and fabrication flexibility due to its face-centered cubic crystal structure, which resists grain growth and cracking during welding, making it ideal for complex chemical equipment designs. Ferritic steel, with its body-centered cubic structure, exhibits lower weldability, higher susceptibility to grain growth, and potential for brittleness in welded zones, requiring careful control of welding parameters. Your choice between these alloys should consider the need for ease of fabrication and the operating environment to ensure structural integrity and performance in chemical processing applications.

Performance in Aggressive Chemical Environments

Austenitic steel exhibits superior corrosion resistance in aggressive chemical environments due to its high chromium and nickel content, making it ideal for handling acidic or oxidizing substances. Ferritic steel, while resistant to stress corrosion cracking and less expensive, generally lacks the same level of chemical durability and is more prone to corrosion in chloride-rich conditions. Choosing austenitic steel for your chemical equipment ensures enhanced longevity and reliability in harsh environments.

Temperature Resistance and Stability

Austenitic steel offers superior temperature resistance and stability in chemical equipment due to its high chromium and nickel content, allowing it to withstand temperatures up to 1,100degF (600degC) without losing strength or corrosion resistance. Ferritic steel, while more resistant to stress corrosion cracking, performs best at lower temperatures, typically up to 900degF (482degC), and may experience reduced toughness and scaling at higher temperatures. Your choice between these steels should consider the operating temperature range and the need for maintaining structural integrity and chemical resistance under thermal stress.

Cost Considerations and Lifecycle Analysis

Austenitic steel typically involves higher initial costs due to its complex alloying elements like nickel and chromium, which enhance corrosion resistance and mechanical properties essential for chemical equipment operating under aggressive conditions. Ferritic steel, containing lower nickel content and higher iron, offers a cost-effective alternative with moderate corrosion resistance, making it suitable for less demanding chemical processes with shorter lifecycle requirements. Lifecycle analysis reveals that while austenitic steel demands greater upfront investment, its superior durability and reduced maintenance costs can result in lower total cost of ownership compared to ferritic steel, especially in environments prone to high corrosion and thermal stress.

Suitability and Application Scenarios in Chemical Equipment

Austenitic steel offers superior corrosion resistance and excellent toughness, making it ideal for chemical equipment exposed to aggressive acids and high temperatures. Ferritic steel, with its magnetic properties and good stress corrosion cracking resistance, suits less corrosive environments and is often used in structural components and moderate chemical handling. Your choice between these steels should align with the chemical process requirements, operating conditions, and desired longevity of the equipment.

Austenitic steel vs ferritic steel (chemical equipment context) Infographic

libmatt.com

libmatt.com