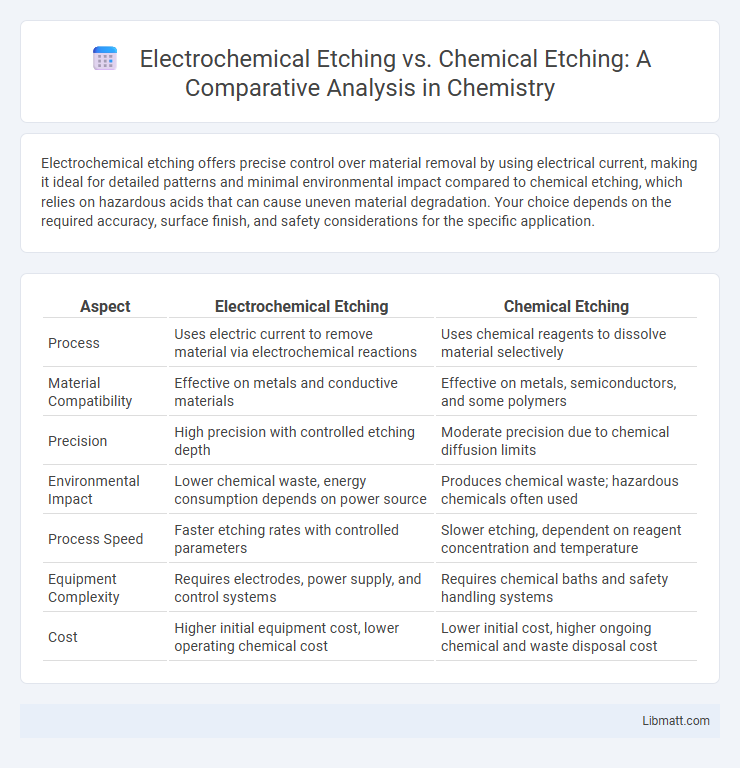

Electrochemical etching offers precise control over material removal by using electrical current, making it ideal for detailed patterns and minimal environmental impact compared to chemical etching, which relies on hazardous acids that can cause uneven material degradation. Your choice depends on the required accuracy, surface finish, and safety considerations for the specific application.

Table of Comparison

| Aspect | Electrochemical Etching | Chemical Etching |

|---|---|---|

| Process | Uses electric current to remove material via electrochemical reactions | Uses chemical reagents to dissolve material selectively |

| Material Compatibility | Effective on metals and conductive materials | Effective on metals, semiconductors, and some polymers |

| Precision | High precision with controlled etching depth | Moderate precision due to chemical diffusion limits |

| Environmental Impact | Lower chemical waste, energy consumption depends on power source | Produces chemical waste; hazardous chemicals often used |

| Process Speed | Faster etching rates with controlled parameters | Slower etching, dependent on reagent concentration and temperature |

| Equipment Complexity | Requires electrodes, power supply, and control systems | Requires chemical baths and safety handling systems |

| Cost | Higher initial equipment cost, lower operating chemical cost | Lower initial cost, higher ongoing chemical and waste disposal cost |

Introduction to Etching Processes

Electrochemical etching uses an electrical current to remove material from a metal surface, allowing precise control over depth and pattern intricacies, making it ideal for detailed designs and fine features. Chemical etching involves immersing the metal in a corrosive solution that selectively dissolves exposed areas, offering a simpler and cost-effective method suited for larger, less detailed patterns. Both processes play crucial roles in manufacturing industries like aerospace, electronics, and jewelry, where accurate metal shaping and surface texturing are essential.

What is Electrochemical Etching?

Electrochemical etching is a precision marking process that uses an electrical current to remove metal from a surface through an electrolytic solution, creating clean, permanent designs or text. This technique offers greater control and environmental safety compared to traditional chemical etching, which relies on acidic or corrosive chemicals to etch metal surfaces. Your choice of electrochemical etching enhances accuracy, reduces chemical waste, and improves overall durability of the etched patterns.

Understanding Chemical Etching

Chemical etching involves the use of corrosive acid solutions to selectively remove material from a metal surface, producing intricate patterns with high precision. This process relies on controlled chemical reactions that dissolve specific areas of the substrate based on resist patterns, making it suitable for delicate and complex designs in metals like stainless steel and copper. Unlike electrochemical etching, which uses electrical current for material removal, chemical etching depends solely on the chemical properties of the etchants and the material being etched.

Materials Suitable for Each Etching Method

Electrochemical etching is highly effective for conductive materials like stainless steel, titanium, and aluminum alloys, as it relies on an electrical current to selectively remove metal. Chemical etching excels with both metals and non-metals, including copper, brass, and certain plastics, utilizing chemical solutions to dissolve surface layers without electrical input. Choosing the appropriate method depends on material conductivity, desired precision, and surface finish requirements.

Process Mechanism: Electrochemical vs Chemical Etching

Electrochemical etching leverages an electric current to selectively remove material by oxidizing or reducing the substrate, enabling precise control over etching depth and pattern fidelity. Chemical etching relies on the direct chemical reaction between the etchant solution and the material surface, typically resulting in isotropic material removal that can be less controlled. The electrochemical process offers enhanced selectivity and cleaner etch profiles compared to chemical etching, which often involves broader, less directional material dissolution.

Key Advantages of Electrochemical Etching

Electrochemical etching offers precise control over depth and pattern fidelity, making it ideal for detailed and repeatable markings on metals. Unlike chemical etching, it produces minimal environmental waste and reduces the use of harsh chemicals, enhancing workplace safety. Your production process benefits from faster cycle times and lower operating costs due to its efficiency and automation compatibility.

Key Benefits of Chemical Etching

Chemical etching offers superior precision and fine-detail capabilities compared to electrochemical etching, making it ideal for producing intricate patterns and complex designs in metals. It provides a clean, non-contact process that minimizes mechanical stress and material deformation, ensuring high-quality surface finishes. You benefit from cost-effective scalability and minimal tooling wear, which reduces production costs for small to medium batch runs.

Applications and Industry Usage

Electrochemical etching is widely used in the electronics and aerospace industries for precision marking and creating microstructures on metals, benefiting from its high accuracy and minimal material damage. Chemical etching finds extensive applications in manufacturing semiconductor devices, printed circuit boards (PCBs), and decorative metal components due to its ability to process complex patterns on thin materials at a lower cost. Both methods serve critical roles in automotive industries for component labeling and quality control, with electrochemical etching preferred for durability and chemical etching favored for large-scale production.

Comparative Analysis: Efficiency, Precision, and Cost

Electrochemical etching offers higher precision and faster processing times due to controlled current application, making it ideal for intricate designs, whereas chemical etching involves longer exposure to corrosive acids, resulting in less accuracy and slower throughput. In terms of efficiency, electrochemical etching reduces material waste and energy consumption by targeting specific areas through selective current flow, while chemical etching consumes more reagents and generates hazardous waste requiring extensive disposal measures. Cost-wise, initial investment for electrochemical systems is higher due to specialized equipment, but operational expenses decrease over time, contrasting with chemical etching's lower setup costs but higher ongoing expenses for chemicals and safety compliance.

Choosing the Right Etching Technique for Your Needs

Electrochemical etching offers precise control and cleaner results by using electric current to remove material, making it suitable for intricate designs on metals such as stainless steel and titanium. Chemical etching employs acid-based solutions to uniformly dissolve metal layers, ideal for large-scale production requiring fine detail but less control over depth. Your choice depends on factors like material type, desired precision, production volume, and environmental considerations, where electrochemical etching excels in accuracy and chemical etching in efficiency.

Electrochemical etching vs chemical etching Infographic

libmatt.com

libmatt.com