Membrane filtration uses a semi-permeable barrier to separate particles based on size, providing higher precision and removal efficiency compared to conventional filtration methods like sand or charcoal filters. You can expect membrane filtration to offer superior contaminant removal, especially for microorganisms and fine particulates, making it ideal for advanced water treatment applications.

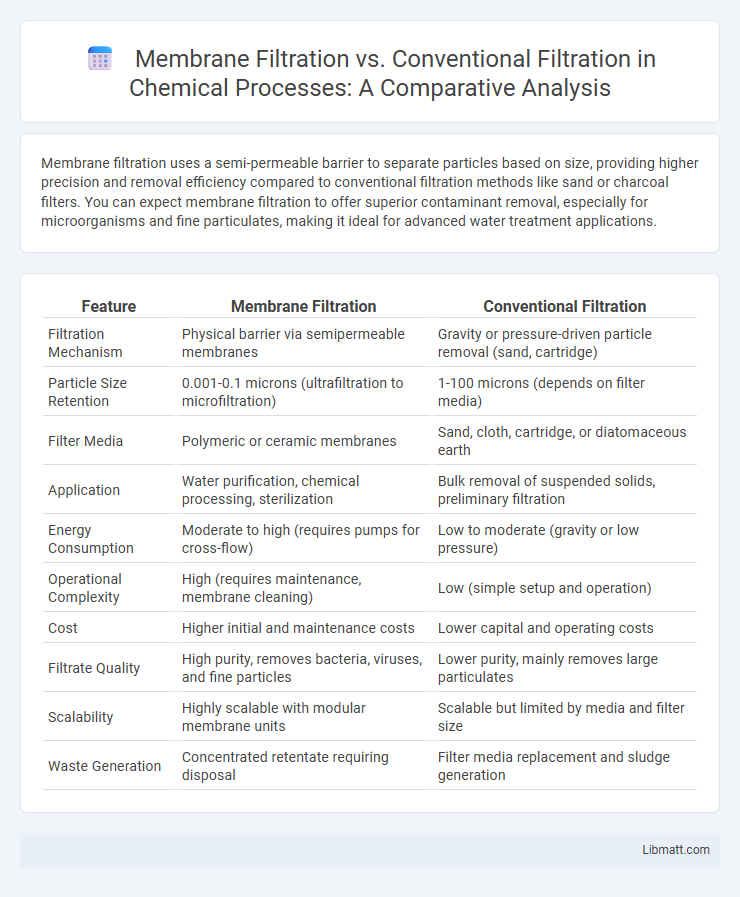

Table of Comparison

| Feature | Membrane Filtration | Conventional Filtration |

|---|---|---|

| Filtration Mechanism | Physical barrier via semipermeable membranes | Gravity or pressure-driven particle removal (sand, cartridge) |

| Particle Size Retention | 0.001-0.1 microns (ultrafiltration to microfiltration) | 1-100 microns (depends on filter media) |

| Filter Media | Polymeric or ceramic membranes | Sand, cloth, cartridge, or diatomaceous earth |

| Application | Water purification, chemical processing, sterilization | Bulk removal of suspended solids, preliminary filtration |

| Energy Consumption | Moderate to high (requires pumps for cross-flow) | Low to moderate (gravity or low pressure) |

| Operational Complexity | High (requires maintenance, membrane cleaning) | Low (simple setup and operation) |

| Cost | Higher initial and maintenance costs | Lower capital and operating costs |

| Filtrate Quality | High purity, removes bacteria, viruses, and fine particles | Lower purity, mainly removes large particulates |

| Scalability | Highly scalable with modular membrane units | Scalable but limited by media and filter size |

| Waste Generation | Concentrated retentate requiring disposal | Filter media replacement and sludge generation |

Introduction to Filtration Technologies

Membrane filtration employs semi-permeable membranes to separate particles based on size and molecular properties, offering precise filtration at micro, ultra, nano, or molecular levels. Conventional filtration relies on physical barriers like sand or activated carbon to remove suspended solids and larger impurities through mechanical trapping. Membrane technology provides higher efficiency and selectivity, enhancing water treatment, food processing, and pharmaceutical applications compared to traditional filtration methods.

Overview of Membrane Filtration

Membrane filtration utilizes semi-permeable membranes to separate particles and solutes based on size and molecular characteristics, offering higher precision compared to conventional filtration methods such as sand or cartridge filters. This technology enables the removal of bacteria, viruses, and dissolved contaminants, making it essential in water treatment, food processing, and pharmaceutical industries. Advances in membrane materials and configurations have improved filtration efficiency, throughput, and energy consumption, positioning membrane filtration as a superior alternative in applications requiring stringent purity standards.

Understanding Conventional Filtration Methods

Conventional filtration methods rely on gravity or pressure to pass fluids through porous materials, effectively removing larger particles and impurities. These systems typically use media such as sand, gravel, or cloth filters, which can trap suspended solids but may allow smaller contaminants to pass through. Understanding these limitations helps you evaluate when membrane filtration, known for its ability to reject microscopic particles and microorganisms, offers a more advanced water purification solution.

Key Differences Between Membrane and Conventional Filtration

Membrane filtration uses a selective barrier to physically separate particles based on size, enabling the removal of viruses, bacteria, and suspended solids with high precision, while conventional filtration relies on gravity or mechanical strainers to exclude larger particles. Membrane systems operate under pressure and provide consistent filtration quality, whereas conventional methods may suffer from varying performance due to pore size variability and clogging. Your choice of filtration technology should consider factors such as contaminant type, required water purity, operational costs, and maintenance needs.

Filtration Efficiency and Performance Comparison

Membrane filtration offers superior filtration efficiency by removing particles as small as 0.01 microns, outperforming conventional filtration which typically limits at 1-5 microns. Membrane technology provides consistent performance under varying flow rates and pressure conditions, enhancing reliability in water and air purification applications. Conventional filtration, while cost-effective for larger particulates, struggles with fine contaminants and often requires frequent maintenance compared to membrane systems.

Applications in Water and Wastewater Treatment

Membrane filtration offers superior removal of pathogens, suspended solids, and dissolved contaminants compared to conventional filtration methods, making it highly effective in producing potable water and treating industrial wastewater. Applications include microfiltration, ultrafiltration, nanofiltration, and reverse osmosis processes, which target specific contaminants such as bacteria, viruses, heavy metals, and organic compounds. Conventional filtration techniques like sand filtration and coagulation-flocculation are primarily used for pretreatment or large-scale water clarification but lack the precision and contaminant removal efficiency of advanced membrane technologies.

Operational Costs and Maintenance Requirements

Membrane filtration systems typically incur higher upfront operational costs due to advanced materials and technology but offer lower ongoing maintenance expenses as they require less frequent replacement and chemical cleaning compared to conventional filtration. Conventional filtration often involves increased labor and consumable costs because of regular media replacement and backwashing requirements. Over time, membrane filtration tends to provide cost efficiencies through reduced downtime and improved filtration consistency.

Environmental Impact and Sustainability

Membrane filtration significantly reduces environmental impact by minimizing chemical usage and waste production compared to conventional filtration, which often relies on chemical additives and generates higher volumes of sludge. Membrane systems offer greater water recovery rates and energy efficiency, promoting sustainability through lower resource consumption and the potential for recycling and reuse of treated water. These factors position membrane filtration as a more sustainable choice for industries aiming to reduce their ecological footprint and achieve long-term environmental compliance.

Challenges and Limitations of Each Filtration Method

Membrane filtration faces challenges such as membrane fouling, high energy consumption, and limited lifespan, which can increase operational costs and maintenance requirements. Conventional filtration methods often struggle with lower contaminant removal efficiency, larger equipment footprint, and the need for frequent filter media replacement. Both methods require careful selection based on water quality and treatment goals to optimize performance and cost-effectiveness.

Future Trends in Filtration Technology

Membrane filtration is rapidly advancing with innovations like nanofiltration and forward osmosis, offering superior contaminant removal and energy efficiency compared to conventional filtration methods. Emerging trends emphasize integrating smart sensors and AI for real-time monitoring and process optimization, enhancing membrane lifespan and performance. The global market is projected to grow significantly, driven by demands in wastewater treatment, food processing, and pharmaceuticals, positioning membrane technology as the future standard in filtration.

Membrane filtration vs conventional filtration Infographic

libmatt.com

libmatt.com