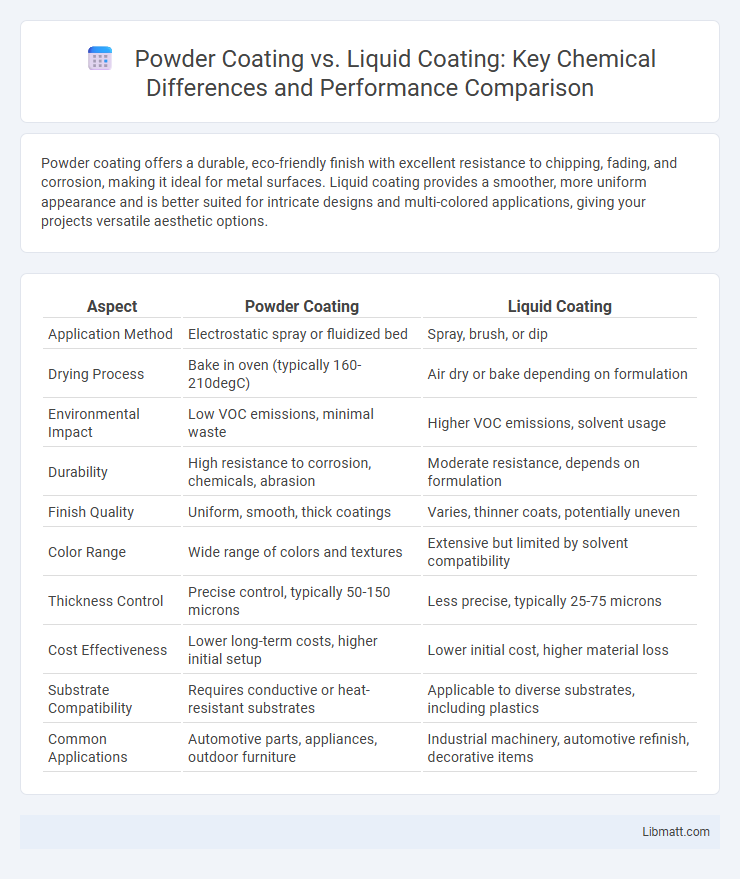

Powder coating offers a durable, eco-friendly finish with excellent resistance to chipping, fading, and corrosion, making it ideal for metal surfaces. Liquid coating provides a smoother, more uniform appearance and is better suited for intricate designs and multi-colored applications, giving your projects versatile aesthetic options.

Table of Comparison

| Aspect | Powder Coating | Liquid Coating |

|---|---|---|

| Application Method | Electrostatic spray or fluidized bed | Spray, brush, or dip |

| Drying Process | Bake in oven (typically 160-210degC) | Air dry or bake depending on formulation |

| Environmental Impact | Low VOC emissions, minimal waste | Higher VOC emissions, solvent usage |

| Durability | High resistance to corrosion, chemicals, abrasion | Moderate resistance, depends on formulation |

| Finish Quality | Uniform, smooth, thick coatings | Varies, thinner coats, potentially uneven |

| Color Range | Wide range of colors and textures | Extensive but limited by solvent compatibility |

| Thickness Control | Precise control, typically 50-150 microns | Less precise, typically 25-75 microns |

| Cost Effectiveness | Lower long-term costs, higher initial setup | Lower initial cost, higher material loss |

| Substrate Compatibility | Requires conductive or heat-resistant substrates | Applicable to diverse substrates, including plastics |

| Common Applications | Automotive parts, appliances, outdoor furniture | Industrial machinery, automotive refinish, decorative items |

Introduction to Powder Coating and Liquid Coating

Powder coating and liquid coating are two prevalent methods for applying protective and decorative finishes on metal surfaces. Powder coating uses a dry powder applied electrostatically and then cured under heat to form a durable skin, while liquid coating involves spraying or brushing liquid paint that dries to a solid film. Your choice between powder and liquid coating hinges on factors like environmental impact, finish quality, and application speed.

How Powder Coating Works

Powder coating works by applying a dry powder, usually composed of thermoplastic or thermoset polymer resins, electrostatically onto a metal surface, which is then cured under heat to form a durable, protective finish. The charged powder particles adhere evenly to the surface, creating a thick, uniform coating that resists chipping, scratching, and corrosion better than traditional liquid coatings. Understanding this process helps you choose the right coating method for enhanced durability and long-lasting protection of your metal products.

How Liquid Coating Works

Liquid coating involves applying a fluid paint or resin onto a surface using spray guns, rollers, or brushes, where it forms a protective and decorative layer as it dries or cures. The coating chemically bonds with the substrate, providing excellent adhesion, color uniformity, and resistance to environmental factors. You can achieve precise finishes and complex textures with liquid coatings, making them ideal for detailed or uneven surfaces.

Surface Preparation Requirements

Powder coating requires a thoroughly cleaned, degreased, and pre-treated surface, often involving abrasive blasting or chemical etching to ensure strong adhesion and uniform finish. Liquid coating also demands proper surface cleaning and sometimes priming but generally allows for more flexibility with irregular or complex shapes. Both methods benefit from removing contaminants like rust, oils, and dust to maximize coating durability and appearance.

Application Processes Compared

Powder coating involves applying a dry, powdered material electrostatically to a surface, followed by curing in an oven to form a hard finish, while liquid coating uses solvent-based or water-based paints applied via spraying, brushing, or dipping, drying through evaporation. Powder coating typically provides a thicker, more durable finish with less environmental impact due to low VOC emissions, whereas liquid coating allows for more precise color matching and smoother textures. Your choice depends on factors like the desired finish, substrate type, and production volume.

Durability and Performance

Powder coating offers superior durability and resistance to chipping, scratching, and fading compared to liquid coating, making it ideal for high-impact environments. Its thicker application and curing process create a tougher, uniform finish that enhances corrosion protection and longevity. Choosing powder coating for your projects ensures enhanced performance and long-lasting aesthetic appeal in demanding conditions.

Environmental Impact and Safety

Powder coating produces minimal volatile organic compounds (VOCs), significantly reducing air pollution compared to traditional liquid coatings that release high levels of harmful solvents. The overspray from powder coating can be recycled, minimizing waste and environmental contamination, whereas liquid coatings generate more hazardous waste requiring careful disposal. Safety benefits of powder coating include a lower fire hazard due to the absence of flammable solvents and reduced exposure to toxic chemicals for workers, enhancing workplace health standards.

Cost Differences and Considerations

Powder coating generally offers lower overall costs due to reduced material waste and faster application times compared to liquid coating, which requires solvents and longer drying periods. Initial equipment investment for powder coating can be higher, but operational expenses tend to be lower because of minimal VOC emissions and energy-efficient curing processes. Liquid coating may present lower upfront costs but often incurs higher maintenance and environmental compliance expenses over time.

Suitable Applications for Each Method

Powder coating is ideal for industrial applications requiring durable, corrosion-resistant finishes on metal parts such as automotive components, appliances, and outdoor furniture. Liquid coating excels in providing smooth, detailed finishes on complex shapes, wood, plastics, and surfaces needing multiple color layers or touch-ups. You can choose powder coating for heavy-duty protection and liquid coating for versatility and precision in decorative or intricate projects.

Choosing the Right Coating for Your Project

Choosing the right coating for your project depends on factors like durability, application method, and environmental impact. Powder coating offers a thicker, more uniform finish that resists chipping and corrosion, making it ideal for outdoor and heavy-use items. Liquid coating provides greater versatility with color options and ease of touch-up, suitable for intricate designs and indoor applications where precision is key.

powder coating vs liquid coating Infographic

libmatt.com

libmatt.com