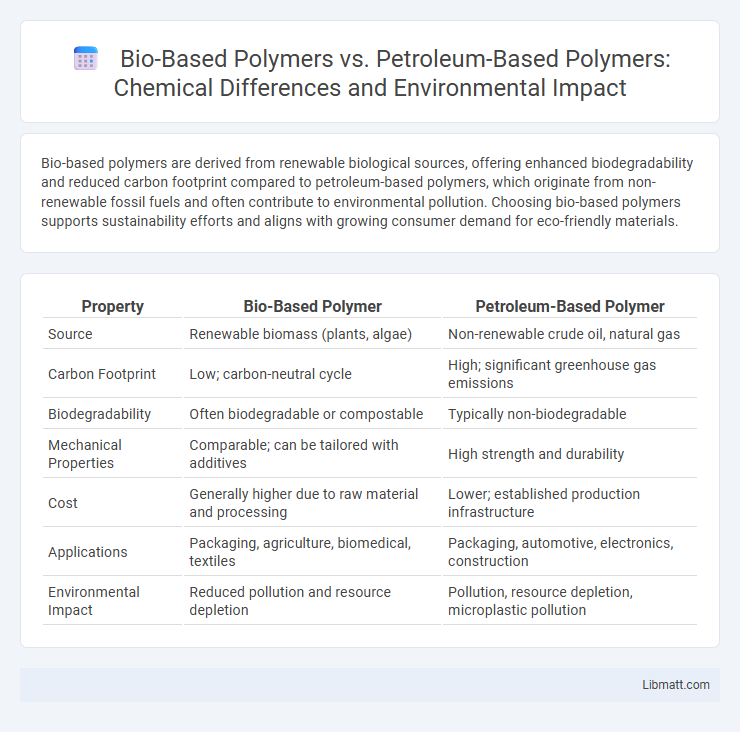

Bio-based polymers are derived from renewable biological sources, offering enhanced biodegradability and reduced carbon footprint compared to petroleum-based polymers, which originate from non-renewable fossil fuels and often contribute to environmental pollution. Choosing bio-based polymers supports sustainability efforts and aligns with growing consumer demand for eco-friendly materials.

Table of Comparison

| Property | Bio-Based Polymer | Petroleum-Based Polymer |

|---|---|---|

| Source | Renewable biomass (plants, algae) | Non-renewable crude oil, natural gas |

| Carbon Footprint | Low; carbon-neutral cycle | High; significant greenhouse gas emissions |

| Biodegradability | Often biodegradable or compostable | Typically non-biodegradable |

| Mechanical Properties | Comparable; can be tailored with additives | High strength and durability |

| Cost | Generally higher due to raw material and processing | Lower; established production infrastructure |

| Applications | Packaging, agriculture, biomedical, textiles | Packaging, automotive, electronics, construction |

| Environmental Impact | Reduced pollution and resource depletion | Pollution, resource depletion, microplastic pollution |

Introduction to Bio-Based and Petroleum-Based Polymers

Bio-based polymers are derived from renewable biological sources such as plants, algae, and microorganisms, offering an eco-friendly alternative to traditional petroleum-based polymers produced from fossil fuels. These bio-based polymers often demonstrate biodegradability and reduced carbon footprints, aligning with sustainable development goals. Your choice between bio-based and petroleum-based polymers impacts environmental sustainability, resource depletion, and recycling processes in various industrial applications.

Raw Material Sources and Availability

Bio-based polymers are derived from renewable resources such as corn, sugarcane, and cellulose, ensuring a more sustainable and often abundant supply compared to petroleum-based polymers, which rely on finite fossil fuels extracted from underground reserves. The availability of bio-based raw materials can depend on agricultural production and land use, potentially influencing cost and scalability. Your choice between these polymers impacts environmental sustainability and resource security, as bio-based polymers help reduce dependency on non-renewable petrochemical feedstocks.

Manufacturing Processes and Energy Consumption

Bio-based polymers are typically produced through fermentation, enzymatic reactions, or polymerization of renewable biomass-derived monomers, requiring less fossil fuel input compared to petroleum-based polymers, which rely heavily on energy-intensive refining and cracking processes of crude oil. The manufacturing of bio-based polymers often consumes lower greenhouse gas emissions and energy, although energy use varies depending on feedstock cultivation and processing technologies. In contrast, petroleum-based polymer production entails higher energy consumption due to complex extraction, distillation, and polymerization stages associated with non-renewable fossil resources.

Environmental Impact and Sustainability

Bio-based polymers significantly reduce greenhouse gas emissions and reliance on finite fossil resources by utilizing renewable biomass feedstocks, enhancing environmental sustainability. Petroleum-based polymers contribute to pollution, non-biodegradability, and elevated carbon footprints due to their dependence on fossil fuels and energy-intensive production processes. Transitioning to bio-based polymers supports circular economy principles, promoting biodegradability, reduced waste, and lower environmental impact throughout the lifecycle.

Performance and Mechanical Properties Comparison

Bio-based polymers often exhibit competitive mechanical properties such as tensile strength and flexibility when compared to petroleum-based polymers, although they may face limitations in thermal stability and durability under extreme conditions. Innovations in bio-based polymer composites and additives have enhanced performance characteristics, making them suitable for applications ranging from packaging to automotive parts. Your choice between bio-based and petroleum-based polymers should consider specific performance requirements like impact resistance and elongation at break for optimal material selection.

Applications in Various Industries

Bio-based polymers are increasingly used in packaging, agriculture, and biomedical industries due to their biodegradability and renewable origins, reducing environmental impact. Petroleum-based polymers dominate in automotive, construction, and electronics for their durability and cost-effectiveness, though they contribute to pollution and resource depletion. Your choice between these polymers affects sustainability goals and product performance across diverse industrial applications.

Biodegradability and End-of-Life Options

Bio-based polymers typically exhibit enhanced biodegradability compared to petroleum-based polymers, breaking down more readily in natural environments through microbial activity. End-of-life options for bio-based polymers often include industrial composting and anaerobic digestion, offering sustainable disposal techniques that reduce environmental impact. In contrast, petroleum-based polymers primarily rely on recycling or landfill deposition, where degradation is slower and can contribute substantially to persistent plastic pollution.

Economic Considerations and Market Trends

Bio-based polymers offer a growing market advantage due to increasing consumer demand for sustainable materials and government incentives promoting eco-friendly production. Petroleum-based polymers currently dominate the market with lower production costs and established supply chains but face volatility in crude oil prices affecting economic stability. Innovations in bio-based polymer manufacturing and economies of scale are expected to reduce costs, shifting market trends towards greener alternatives.

Regulatory Frameworks and Industry Standards

Bio-based polymers are increasingly favored under evolving regulatory frameworks that promote sustainability and reduce carbon footprints, aligning with international standards such as ASTM D6866 for biobased content measurement. Petroleum-based polymers face stricter regulations due to concerns over environmental pollution and fossil fuel dependence, with industry standards pushing for improved recyclability and lifecycle assessments. Understanding these regulatory trends helps you navigate compliance and leverage bio-based polymers for greener product innovation.

Future Outlook and Innovation in Polymer Technologies

Bio-based polymers are gaining momentum due to their sustainability and reduced environmental impact compared to traditional petroleum-based polymers, which face increasing regulatory and consumer pressure. Innovations in polymer technologies focus on enhancing the mechanical properties and biodegradability of bio-based materials while improving cost-efficiency and scalability for industrial applications. Your choice of bio-based polymers supports a future where materials are derived from renewable resources, driving advancements in green chemistry and circular economy initiatives.

bio-based polymer vs petroleum-based polymer Infographic

libmatt.com

libmatt.com