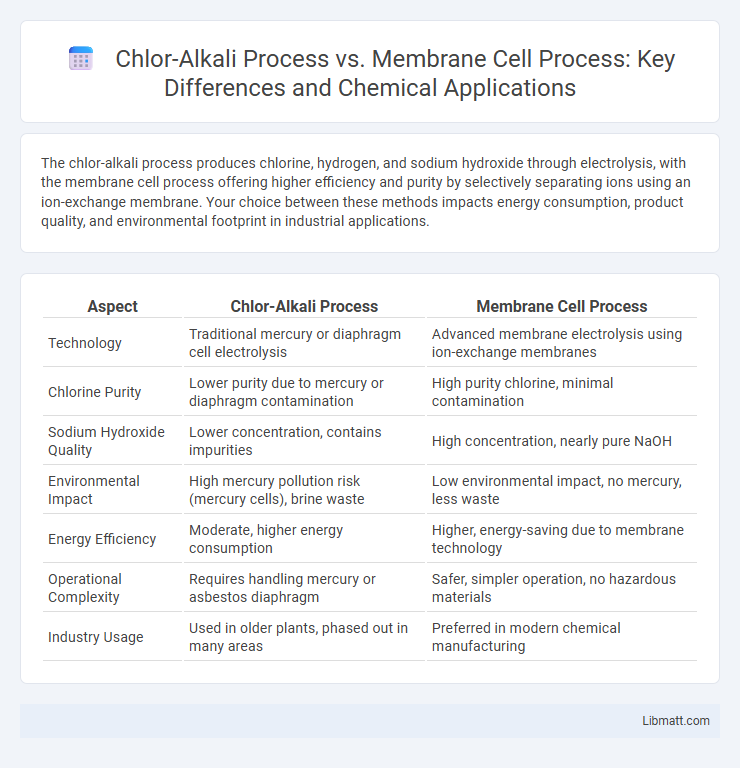

The chlor-alkali process produces chlorine, hydrogen, and sodium hydroxide through electrolysis, with the membrane cell process offering higher efficiency and purity by selectively separating ions using an ion-exchange membrane. Your choice between these methods impacts energy consumption, product quality, and environmental footprint in industrial applications.

Table of Comparison

| Aspect | Chlor-Alkali Process | Membrane Cell Process |

|---|---|---|

| Technology | Traditional mercury or diaphragm cell electrolysis | Advanced membrane electrolysis using ion-exchange membranes |

| Chlorine Purity | Lower purity due to mercury or diaphragm contamination | High purity chlorine, minimal contamination |

| Sodium Hydroxide Quality | Lower concentration, contains impurities | High concentration, nearly pure NaOH |

| Environmental Impact | High mercury pollution risk (mercury cells), brine waste | Low environmental impact, no mercury, less waste |

| Energy Efficiency | Moderate, higher energy consumption | Higher, energy-saving due to membrane technology |

| Operational Complexity | Requires handling mercury or asbestos diaphragm | Safer, simpler operation, no hazardous materials |

| Industry Usage | Used in older plants, phased out in many areas | Preferred in modern chemical manufacturing |

Introduction to the Chlor-Alkali Process

The Chlor-Alkali process produces chlorine, caustic soda, and hydrogen by electrolyzing brine solution, a critical industrial method for many chemical applications. The membrane cell process, a modern variation, uses selective membranes to separate chlorine and hydroxide ions efficiently, enhancing product purity and energy efficiency. Your choice between these processes impacts environmental compliance and operational costs, given the membrane method's reduced mercury and asbestos risks compared to traditional mercury or diaphragm cells.

Overview of the Membrane Cell Process

The membrane cell process in chlor-alkali production utilizes an ion-selective membrane to separate the anode and cathode compartments, preventing the mixing of chlorine and hydrogen gases while allowing sodium ions to pass through. This method improves product purity and energy efficiency compared to traditional mercury or diaphragm cell processes by minimizing contamination and reducing energy consumption. Your choice of the membrane cell process leads to a more environmentally friendly and cost-effective production of chlorine, caustic soda, and hydrogen.

Historical Development and Evolution

The chlor-alkali process originated in the late 19th century using mercury cells and diaphragm cells, which were energy-intensive and environmentally hazardous. The membrane cell process emerged in the mid-20th century as a cleaner alternative, utilizing ion-exchange membranes to improve energy efficiency and reduce mercury pollution. Your understanding of the chlor-alkali industry's evolution highlights the shift toward sustainable and eco-friendly production methods through membrane technology advancements.

Chemical Reactions: Similarities and Differences

The Chlor-alkali process and the membrane cell process both produce chlorine, hydrogen, and sodium hydroxide through the electrolysis of brine, but their chemical reactions differ in the method of ion separation. In the mercury cell and diaphragm cell variants of the Chlor-alkali process, the reactions involve cathodic reduction of water to form hydrogen gas and anodic oxidation of chloride ions to release chlorine gas, with sodium ions migrating through a mercury or porous diaphragm. The membrane cell process uses an ion-exchange membrane that selectively allows sodium ions to pass while preventing chlorine and hydroxide ions from mixing, resulting in purer sodium hydroxide and higher energy efficiency in your industrial applications.

Key Equipment in Each Process

The Chlor-alkali process primarily utilizes mercury cells, diaphragm cells, or membrane cells, each involving distinct key equipment such as mercury cathodes in mercury cells and asbestos diaphragms in diaphragm cells. The membrane cell process employs an ion-exchange membrane that separates the anode and cathode compartments, preventing chlorine and hydrogen gases from mixing while allowing selective ion flow. Your choice between these methods affects operational efficiency, environmental impact, and equipment maintenance requirements.

Energy Efficiency Comparison

The membrane cell process exhibits significantly higher energy efficiency compared to the traditional chlor-alkali process, consuming approximately 20-30% less electrical energy per ton of chlorine produced. This improvement is attributed to the membrane's selective ion exchange properties, which reduce electrical resistance and minimize hydrogen and oxygen recombination losses. Advances in membrane materials and cell design further optimize power consumption, making the membrane cell process the preferred choice for sustainable chlor-alkali production.

Environmental Impact and Safety Considerations

The Chlor-alkali process using mercury and diaphragm cells poses significant environmental risks, including mercury pollution and brine discharge containing harmful chemicals, which can contaminate water sources. In contrast, the membrane cell process reduces hazardous waste by utilizing ion-selective membranes and eliminates mercury usage, greatly minimizing toxic emissions and environmental harm. Safety considerations favor the membrane cell process due to lower chemical handling risks, improved energy efficiency, and reduced toxic byproducts, promoting safer industrial operations and environmental compliance.

Product Purity and Quality

The membrane cell process in the chlor-alkali industry produces higher purity sodium hydroxide and chlorine due to minimal contamination from mercury or diaphragm materials. Chlor-alkali processes using mercury or diaphragm cells often result in lower product purity because of metal or fiber contaminants that require additional purification steps. Membrane technology ensures improved product quality by reducing impurities and enabling consistent, high-grade chemical output beneficial for sensitive chemical applications.

Economic Factors and Cost Analysis

The chlor-alkali process using membrane cells offers significant economic advantages due to lower energy consumption and reduced raw material costs compared to traditional mercury and diaphragm cells. Membrane cells require less maintenance and produce higher purity products, minimizing downstream processing expenses and enhancing overall cost efficiency. Capital investments are higher initially, but operational savings and compliance with environmental regulations make membrane technology more cost-effective in the long term.

Future Trends in Chlor-Alkali Technology

Future trends in chlor-alkali technology emphasize the membrane cell process due to its higher energy efficiency and reduced environmental impact compared to traditional mercury and diaphragm cells. Innovations in membrane materials and improved cell design are driving lower electricity consumption and higher product purity, making your chlor-alkali operations more sustainable and cost-effective. Advancements in renewable energy integration and digital monitoring systems will further optimize membrane cell performance and support green production goals.

Chlor-alkali process vs membrane cell process Infographic

libmatt.com

libmatt.com