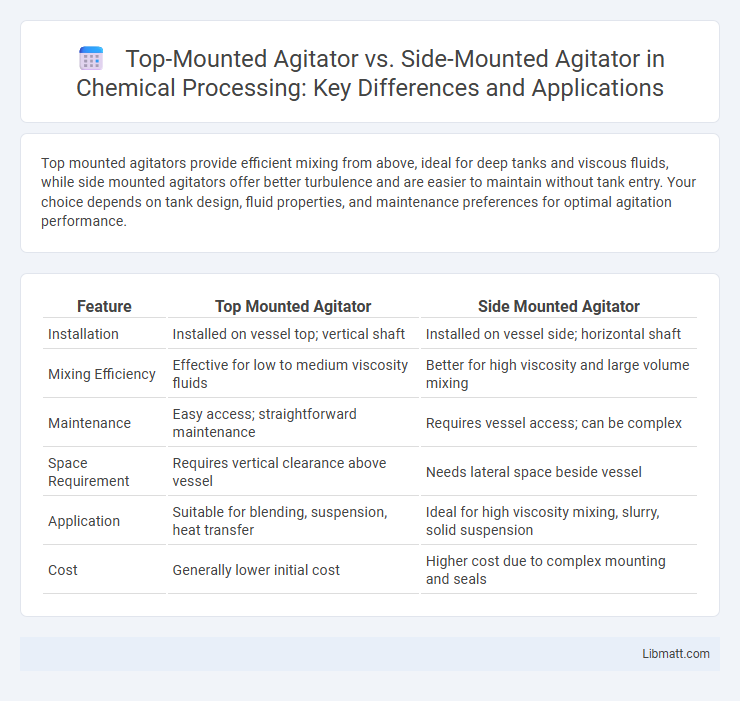

Top mounted agitators provide efficient mixing from above, ideal for deep tanks and viscous fluids, while side mounted agitators offer better turbulence and are easier to maintain without tank entry. Your choice depends on tank design, fluid properties, and maintenance preferences for optimal agitation performance.

Table of Comparison

| Feature | Top Mounted Agitator | Side Mounted Agitator |

|---|---|---|

| Installation | Installed on vessel top; vertical shaft | Installed on vessel side; horizontal shaft |

| Mixing Efficiency | Effective for low to medium viscosity fluids | Better for high viscosity and large volume mixing |

| Maintenance | Easy access; straightforward maintenance | Requires vessel access; can be complex |

| Space Requirement | Requires vertical clearance above vessel | Needs lateral space beside vessel |

| Application | Suitable for blending, suspension, heat transfer | Ideal for high viscosity mixing, slurry, solid suspension |

| Cost | Generally lower initial cost | Higher cost due to complex mounting and seals |

Introduction to Agitator Mounting Types

Top mounted agitators are installed vertically on the tank lid, providing efficient mixing for tall, narrow vessels with centralized shaft support and easier maintenance access. Side mounted agitators attach horizontally to the vessel wall, offering space-saving benefits and improved mixing in shallow tanks or large diameter vessels. Your choice depends on tank design, mixing requirements, and maintenance preferences for optimal agitation performance.

What Is a Top Mounted Agitator?

A top mounted agitator is a mechanical device installed on the upper part of a mixing tank to stir or blend liquids and solids efficiently. This configuration provides easy access for maintenance and allows for versatile mixing capabilities, making it ideal for processes requiring thorough agitation and uniform consistency. Your choice of a top mounted agitator depends on factors like tank size, viscosity of materials, and desired mixing intensity.

What Is a Side Mounted Agitator?

A side mounted agitator is a mechanical device attached to the side of a tank or vessel to mix fluids or slurries efficiently. It offers easy maintenance and reduces shaft length, lowering the risk of bending in larger tanks, while providing uniform mixing. Your choice between a top mounted and side mounted agitator depends on tank design, mixing requirements, and space constraints.

Key Design Differences

Top mounted agitators feature a vertical shaft entering from above, allowing easy access for maintenance and better clearance inside tall tanks, while side mounted agitators attach horizontally, suitable for mixing in shallow tanks or when top access is limited. The design of top mounted agitators typically enables more efficient axial flow patterns ideal for blending and suspension, whereas side mounted agitators create radial flow, promoting heat transfer and gas dispersion. Material construction considerations vary, with top mounted units often using stainless steel for corrosion resistance and side mounted units designed for heavy-duty applications with robust seals to prevent leakage.

Installation and Space Requirements

Top mounted agitators require vertical clearance above the tank and typically involve simpler installation due to direct mounting on the vessel's cover, making them ideal for tanks with limited floor space. Side mounted agitators install horizontally through the tank wall, necessitating more wall space and structural support but allowing easier access for maintenance without disturbing the tank's contents. Space requirements for top mounted agitators emphasize vertical room and roof strength, whereas side mounted designs focus on lateral clearance and tank wall integrity.

Mixing Efficiency and Flow Patterns

Top mounted agitators provide superior mixing efficiency in deep tanks by generating strong axial flow patterns that promote uniform blending and reduce dead zones. Side mounted agitators create radial flow patterns, ideal for blending lighter materials or suspending solids near the tank walls, but may result in lower overall circulation in tall vessels. Selection depends on tank geometry and desired mixing intensity, with top mounted agitators excelling in achieving homogenous mixtures in vertical vessels.

Maintenance and Accessibility

Top mounted agitators offer easier maintenance and accessibility due to direct vertical access, allowing quicker inspection and component replacement without extensive system disassembly. Side mounted agitators may require additional space removal or equipment shutdown for maintenance, complicating accessibility in confined setups. Your maintenance efficiency improves significantly with top mounted designs when regular servicing is critical for operational uptime.

Cost Considerations

Top mounted agitators generally incur higher initial costs due to more complex installation and maintenance requirements, but they offer better mixing efficiency and accessibility that can reduce long-term operational expenses. Side mounted agitators often present a lower upfront investment and simpler installation, making them ideal for budget-sensitive projects with moderate mixing needs. Evaluating the total cost of ownership including energy consumption, maintenance frequency, and application-specific demands is critical when choosing between top and side mounted agitators.

Industry Applications for Each Type

Top mounted agitators are commonly used in industries such as chemical processing, pharmaceuticals, and food manufacturing where precise mixing and uniformity are critical. Side mounted agitators are preferred in wastewater treatment, mining, and large tank applications due to their ability to handle high viscosity fluids and abrasive materials. Your choice between the two should consider the specific mixing requirements and the nature of the materials involved in your industry.

Choosing the Right Agitator for Your Process

Top mounted agitators provide direct drive and efficient mixing in tall tanks, ideal for high-viscosity fluids and processes requiring intense shear. Side mounted agitators offer easy maintenance access and are suited for large, shallow vessels or when tank space is limited, ensuring uniform flow patterns with less energy consumption. Your choice depends on tank design, fluid properties, and process requirements to optimize mixing performance and operational efficiency.

Top mounted agitator vs side mounted agitator Infographic

libmatt.com

libmatt.com