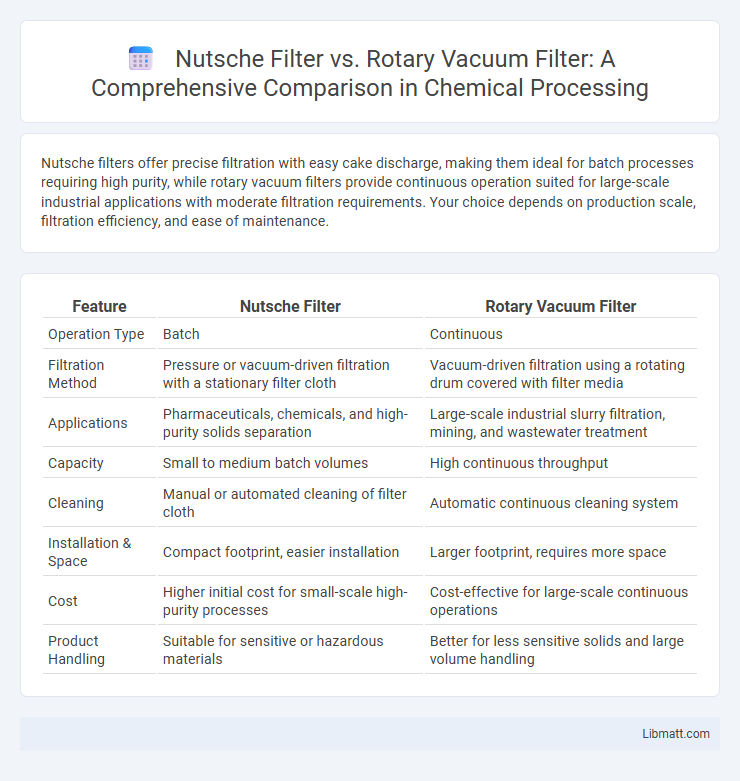

Nutsche filters offer precise filtration with easy cake discharge, making them ideal for batch processes requiring high purity, while rotary vacuum filters provide continuous operation suited for large-scale industrial applications with moderate filtration requirements. Your choice depends on production scale, filtration efficiency, and ease of maintenance.

Table of Comparison

| Feature | Nutsche Filter | Rotary Vacuum Filter |

|---|---|---|

| Operation Type | Batch | Continuous |

| Filtration Method | Pressure or vacuum-driven filtration with a stationary filter cloth | Vacuum-driven filtration using a rotating drum covered with filter media |

| Applications | Pharmaceuticals, chemicals, and high-purity solids separation | Large-scale industrial slurry filtration, mining, and wastewater treatment |

| Capacity | Small to medium batch volumes | High continuous throughput |

| Cleaning | Manual or automated cleaning of filter cloth | Automatic continuous cleaning system |

| Installation & Space | Compact footprint, easier installation | Larger footprint, requires more space |

| Cost | Higher initial cost for small-scale high-purity processes | Cost-effective for large-scale continuous operations |

| Product Handling | Suitable for sensitive or hazardous materials | Better for less sensitive solids and large volume handling |

Introduction to Industrial Filtration Systems

Nutsche filters and rotary vacuum filters are essential components in industrial filtration systems, each designed to efficiently separate solids from liquids in various manufacturing processes. Nutsche filters offer a sealed environment ideal for handling hazardous or air-sensitive materials, providing precise cake washing and drying capabilities. Rotary vacuum filters excel in continuous operation with high throughput, making them suitable for large-scale applications requiring rapid filtration and easy cake discharge.

Overview of Nutsche Filter Technology

Nutsche filter technology employs a closed, pressurized vessel designed for efficient solid-liquid separation, offering precise filtration and washing capabilities in a controlled environment. This filter type is ideal for handling hazardous or sensitive materials, ensuring minimum exposure and contamination risk due to its sealed system. Compared to rotary vacuum filters, Nutsche filters provide superior cake washing and drying performance, making them preferred in pharmaceutical and chemical industries.

Rotary Vacuum Filter: Key Features

Rotary Vacuum Filters offer continuous filtration with a rotating drum covered by a filter medium, facilitating efficient solid-liquid separation in large-scale industrial processes. Their key features include a high filtration rate, automatic cake washing, and a self-cleaning mechanism that reduces downtime and maintenance costs. You can rely on their robust design for handling varying slurry viscosities and improving overall production throughput.

Working Principles: Nutsche vs Rotary Vacuum Filters

Nutsche filters operate by using a stationary cylindrical vessel with a perforated plate to support the filter cake, combined with vacuum or pressure to separate solids from liquids efficiently. Rotary vacuum filters consist of a rotating drum partially submerged in a slurry, where vacuum pressure pulls liquid through the filter medium, allowing continuous cake formation and discharge. While Nutsche filters provide batch processing with precise control over filtration parameters, rotary vacuum filters enable continuous operation suited for large-scale applications.

Filtration Efficiency and Performance Comparison

Nutsche filters achieve higher filtration efficiency due to their closed system design, enabling precise control over pressure and vacuum conditions, which enhances cake washing and minimizes product loss. Rotary vacuum filters offer continuous operation with moderate filtration rates but typically exhibit lower cake dryness and higher moisture content compared to nutsche filters. Performance-wise, nutsche filters excel in handling fine particles and viscous slurries, delivering superior filtration quality and throughput in batch processes.

Application Areas for Each Filter Type

Nutsche filters are primarily used in pharmaceutical, chemical, and food industries for solid-liquid separation involving sensitive materials requiring precise filtration and washing under controlled conditions. Rotary vacuum filters find applications in large-scale mining, wastewater treatment, and chemical industries where continuous filtration of slurries with high throughput is essential. The choice between these filters depends on the material's nature, production scale, and process requirements for filtration efficiency and cake washing.

Advantages of Nutsche Filters

Nutsche filters provide superior filtration efficiency and easier cake discharge compared to rotary vacuum filters, making them ideal for handling thick, sticky slurries. They offer enhanced safety and containment by operating in a closed system, reducing exposure to hazardous materials. The ability to perform washing and drying within the same vessel significantly improves process control and product quality in pharmaceutical and chemical industries.

Advantages of Rotary Vacuum Filters

Rotary vacuum filters offer continuous filtration, enhancing productivity in large-scale operations compared to batch processes like Nutsche filters. They provide uniform cake formation and efficient washing, reducing downtime and improving filtration quality. Their automated operation minimizes labor costs and ensures consistent processing for slurry handling across diverse industries.

Operational and Maintenance Considerations

Nutsche filters require manual handling for cake discharge and thorough cleaning, demanding more frequent maintenance due to their batch operation, while rotary vacuum filters offer continuous operation with automated discharge, resulting in reduced downtime and simpler upkeep. The sealing system in Nutsche filters necessitates regular inspection to prevent leaks, whereas rotary vacuum filters benefit from self-cleaning scrapers that minimize maintenance interventions. Your choice depends on the balance between operational consistency and maintenance resource availability.

Choosing the Right Filter for Your Process

Selecting the right filter depends on your process requirements such as filtration speed, capacity, and cake dryness. Nutsche filters excel in batch operations with precise solid-liquid separation and easy cake discharge, ideal for handling hazardous or sensitive materials. Rotary vacuum filters offer continuous filtration and higher throughput, making them suitable for large-scale industrial processes where constant operation is essential.

Nutsche filter vs rotary vacuum filter Infographic

libmatt.com

libmatt.com