Wet granulation involves using a liquid binder to agglomerate powders, resulting in improved particle cohesion, flow, and compressibility for tablet manufacturing. Dry granulation, on the other hand, compacts powders under pressure without moisture, making it ideal for moisture-sensitive materials while maintaining your formulation's stability.

Table of Comparison

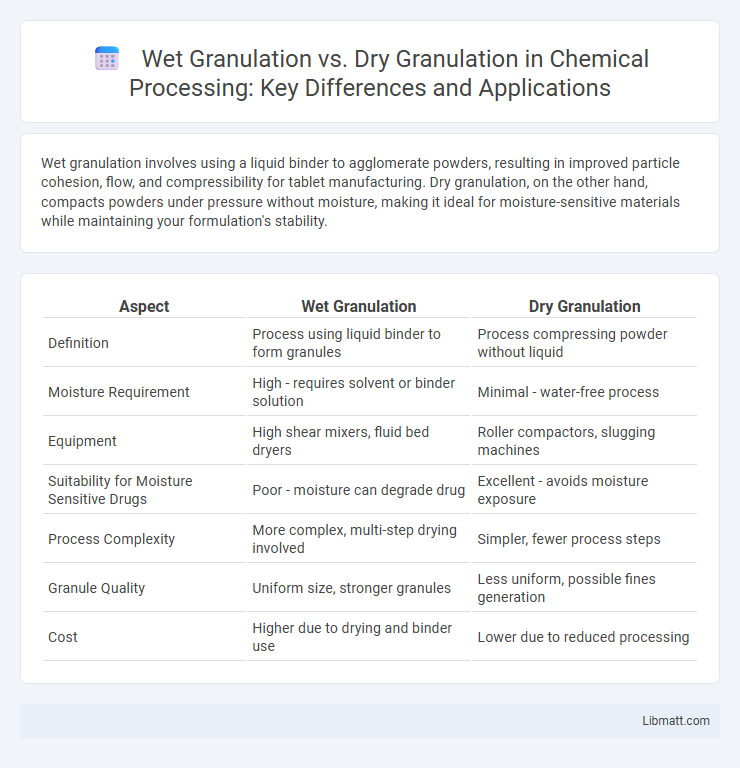

| Aspect | Wet Granulation | Dry Granulation |

|---|---|---|

| Definition | Process using liquid binder to form granules | Process compressing powder without liquid |

| Moisture Requirement | High - requires solvent or binder solution | Minimal - water-free process |

| Equipment | High shear mixers, fluid bed dryers | Roller compactors, slugging machines |

| Suitability for Moisture Sensitive Drugs | Poor - moisture can degrade drug | Excellent - avoids moisture exposure |

| Process Complexity | More complex, multi-step drying involved | Simpler, fewer process steps |

| Granule Quality | Uniform size, stronger granules | Less uniform, possible fines generation |

| Cost | Higher due to drying and binder use | Lower due to reduced processing |

Introduction to Granulation Processes

Granulation processes, essential in pharmaceutical manufacturing, improve powder flow and compaction by forming granules from fine particles. Wet granulation uses a liquid binder to agglomerate powders, enhancing uniformity and compressibility, while dry granulation compacts powders without moisture, suitable for moisture-sensitive materials. Understanding these methods helps optimize Your formulation for stability, dissolution, and tablet quality.

What is Wet Granulation?

Wet granulation is a pharmaceutical process where powder particles are bound together using a liquid solution to form granules, improving powder flow and compressibility for tablet manufacturing. This method enhances drug uniformity and bioavailability by creating dense, porous granules that dissolve more consistently. Your choice between wet and dry granulation depends on the formulation's moisture sensitivity and desired granule properties.

What is Dry Granulation?

Dry granulation is a pharmaceutical manufacturing process where powders are compressed into dense slugs or sheets without the use of liquid binders, enhancing flowability and compressibility. This method is preferred for moisture-sensitive drugs as it avoids exposure to heat and solvents, preserving the stability of active pharmaceutical ingredients (APIs). Equipment such as roller compactors or slugging machines is commonly used to produce granules suitable for tablet formation and capsule filling.

Key Differences Between Wet and Dry Granulation

Wet granulation involves adding a liquid binder to powders to form granules, enhancing particle adhesion and improving flowability, while dry granulation compresses powders without liquid, suitable for moisture-sensitive materials. Wet granulation generally produces more uniform and dense granules, leading to better tablet hardness and dissolution profiles, whereas dry granulation is faster, cost-effective, and avoids drying steps. The choice between wet and dry granulation hinges on material properties, production scale, and desired drug release characteristics.

Advantages of Wet Granulation

Wet granulation improves powder flowability and compressibility, resulting in uniform tablet weight and content. It enhances the binding of particles, reducing dust and segregation issues during tablet production. Your formulations benefit from improved mechanical strength and consistent dissolution profiles through wet granulation.

Advantages of Dry Granulation

Dry granulation offers advantages such as improved stability for moisture-sensitive and heat-sensitive active pharmaceutical ingredients, preventing degradation during processing. It requires no drying step, reducing manufacturing time and energy costs while maintaining consistent particle size distribution. Your formulation benefits from enhanced flow properties and compressibility without exposure to liquids or high temperatures, making it ideal for moisture-labile compounds.

Limitations of Wet Granulation

Wet granulation faces limitations such as sensitivity to moisture and heat, which can degrade temperature-sensitive ingredients or cause instability in formulations. The process requires drying steps that increase production time and energy consumption, making it less efficient for large-scale manufacturing. Equipment complexity and higher costs associated with wet granulation can restrict its use in cost-sensitive pharmaceutical production.

Limitations of Dry Granulation

Dry granulation faces limitations such as lower compressibility compared to wet granulation, leading to weaker tablet strength and potential friability issues. The process is unsuitable for moisture-sensitive materials that require better granule uniformity and dissolution profiles. Additionally, dry granulation may result in poor content uniformity and challenges in achieving optimal particle size distribution.

Criteria for Choosing the Appropriate Granulation Method

Selecting the appropriate granulation method depends on factors such as the moisture sensitivity of the active pharmaceutical ingredient (API), thermal stability, and desired tablet properties. Wet granulation is preferred when improved particle binding and uniformity are needed, especially for formulations sensitive to dust or segregation but can tolerate moisture and heat exposure. Dry granulation suits moisture or heat-sensitive drugs, fragile APIs, or when a fast processing time and low equipment costs are prioritized, offering suitable compressibility without liquid additives.

Applications and Industry Examples

Wet granulation is commonly used in pharmaceutical manufacturing to improve the flow and compressibility of powders, essential for tablet formulation in the production of antibiotics and analgesics. Dry granulation is preferred in industries handling moisture-sensitive ingredients, such as vitamins and certain nutraceuticals, where preservation of chemical stability is critical. Food processing and chemical industries also utilize wet granulation to create uniform particle size in detergents and instant drink mixes, while dry granulation is favored for heat-sensitive materials requiring minimal solvent exposure.

wet granulation vs dry granulation Infographic

libmatt.com

libmatt.com