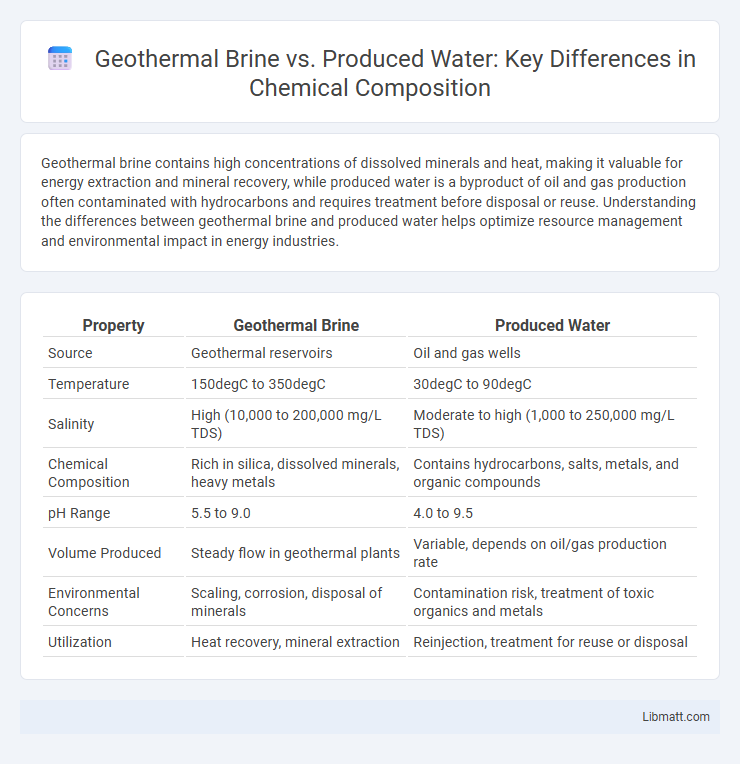

Geothermal brine contains high concentrations of dissolved minerals and heat, making it valuable for energy extraction and mineral recovery, while produced water is a byproduct of oil and gas production often contaminated with hydrocarbons and requires treatment before disposal or reuse. Understanding the differences between geothermal brine and produced water helps optimize resource management and environmental impact in energy industries.

Table of Comparison

| Property | Geothermal Brine | Produced Water |

|---|---|---|

| Source | Geothermal reservoirs | Oil and gas wells |

| Temperature | 150degC to 350degC | 30degC to 90degC |

| Salinity | High (10,000 to 200,000 mg/L TDS) | Moderate to high (1,000 to 250,000 mg/L TDS) |

| Chemical Composition | Rich in silica, dissolved minerals, heavy metals | Contains hydrocarbons, salts, metals, and organic compounds |

| pH Range | 5.5 to 9.0 | 4.0 to 9.5 |

| Volume Produced | Steady flow in geothermal plants | Variable, depends on oil/gas production rate |

| Environmental Concerns | Scaling, corrosion, disposal of minerals | Contamination risk, treatment of toxic organics and metals |

| Utilization | Heat recovery, mineral extraction | Reinjection, treatment for reuse or disposal |

Introduction to Geothermal Brine and Produced Water

Geothermal brine is a high-temperature, mineral-rich fluid extracted from geothermal reservoirs, containing dissolved salts and metals valuable for energy production and resource recovery. Produced water originates from oil and gas wells and consists of water, hydrocarbons, and various contaminants requiring treatment before reuse or disposal. Understanding the characteristics of geothermal brine and produced water is essential for optimizing your extraction processes and managing environmental impact effectively.

Definitions: Geothermal Brine vs Produced Water

Geothermal brine is hot, mineral-rich fluid extracted from deep underground geothermal reservoirs used for energy production, while produced water refers to the water brought to the surface during oil and gas extraction containing hydrocarbons and various dissolved solids. Both fluids require specialized handling and treatment due to their unique chemical compositions, but geothermal brine primarily supports renewable energy processes, whereas produced water is a byproduct of fossil fuel operations. Understanding these definitions helps you manage resource recovery and environmental impact in energy industries effectively.

Chemical Composition Differences

Geothermal brine typically contains higher concentrations of dissolved minerals such as silica, lithium, and boron, with elevated levels of sodium, chloride, and sulfate compared to produced water from oil and gas wells. Produced water often exhibits a broader range of hydrocarbons, heavy metals, and organic contaminants reflecting the reservoir's geological and fluid characteristics. These chemical composition differences influence their treatment methods, potential environmental impacts, and resource recovery applications.

Sources and Extraction Methods

Geothermal brine originates from deep underground reservoirs heated by volcanic activity, extracted through high-temperature wells that tap into geothermal aquifers. Produced water is a byproduct of oil and gas extraction, obtained from hydraulic fracturing or conventional wells, containing hydrocarbons and other contaminants. Extraction methods for geothermal brine involve specialized geothermal wells designed for sustainable heat recovery, whereas produced water is typically managed through separation and treatment processes in petroleum production facilities.

Environmental Impact Comparison

Geothermal brine and produced water differ significantly in environmental impact due to their chemical composition and treatment requirements. Geothermal brine often contains high concentrations of dissolved minerals and heavy metals, requiring advanced treatment to prevent soil and water contamination, whereas produced water from oil and gas operations contains hydrocarbons and salts that pose risks of toxicity and groundwater pollution if not properly managed. Effective disposal and recycling methods for both fluids are crucial to minimize ecological damage and support sustainable resource use.

Treatment and Disposal Challenges

Geothermal brine contains high concentrations of dissolved minerals and heavy metals, posing significant challenges for treatment due to scaling, corrosion, and toxicity risks, requiring advanced technologies like membrane filtration and chemical precipitation. Produced water from oil and gas extraction consists of hydrocarbons, salts, and organic compounds, complicating treatment processes that often include biological treatment, advanced oxidation, and ion exchange to meet environmental discharge standards. Both wastewaters demand careful disposal strategies to prevent groundwater contamination and infrastructure damage, with reinjection into subsurface formations commonly employed to mitigate environmental impact and comply with regulatory frameworks.

Industrial Applications and Uses

Geothermal brine, rich in dissolved minerals and heat, is primarily utilized in industrial applications such as electricity generation through binary cycle power plants and extraction of valuable minerals like lithium and silica. Produced water from oil and gas wells, containing hydrocarbons and contaminants, is often repurposed for enhanced oil recovery, irrigation, or treated for reuse in industrial processes. Understanding the differing chemical compositions of geothermal brine and produced water can help optimize your choice for sustainable industrial applications.

Economic Considerations and Cost Factors

Geothermal brine extraction typically involves higher upfront capital costs due to advanced heat recovery technology and corrosion-resistant materials, but it offers long-term economic benefits through sustainable energy production. Produced water, often a byproduct of oil and gas operations, has lower initial treatment expenses but higher ongoing disposal or treatment costs, impacting your overall cost efficiency. Understanding these cost factors is essential for making informed decisions about resource utilization and project feasibility.

Regulatory Framework and Compliance

Geothermal brine and produced water fall under distinct regulatory frameworks that govern their extraction, disposal, and environmental impact, with agencies like the EPA and state regulators setting strict guidelines. Compliance involves adhering to specific discharge permits, monitoring contaminant levels such as heavy metals and salinity, and managing potential risks to groundwater and surface water resources. Your operations must ensure accurate documentation and adherence to these regulations to avoid penalties and support sustainable resource management.

Future Trends and Innovations

Geothermal brine and produced water management are evolving through advancements in advanced separation technologies and heat recovery systems that enhance energy efficiency and resource reuse. Innovations in mineral extraction from geothermal brine are driving economic viability by recovering valuable metals like lithium, while selective treatment of produced water improves environmental compliance and supports sustainable oil and gas operations. Emerging integration of IoT sensors and AI-driven monitoring optimizes treatment processes, reduces operational costs, and enables real-time data analytics for smarter water resource management.

Geothermal brine vs produced water Infographic

libmatt.com

libmatt.com