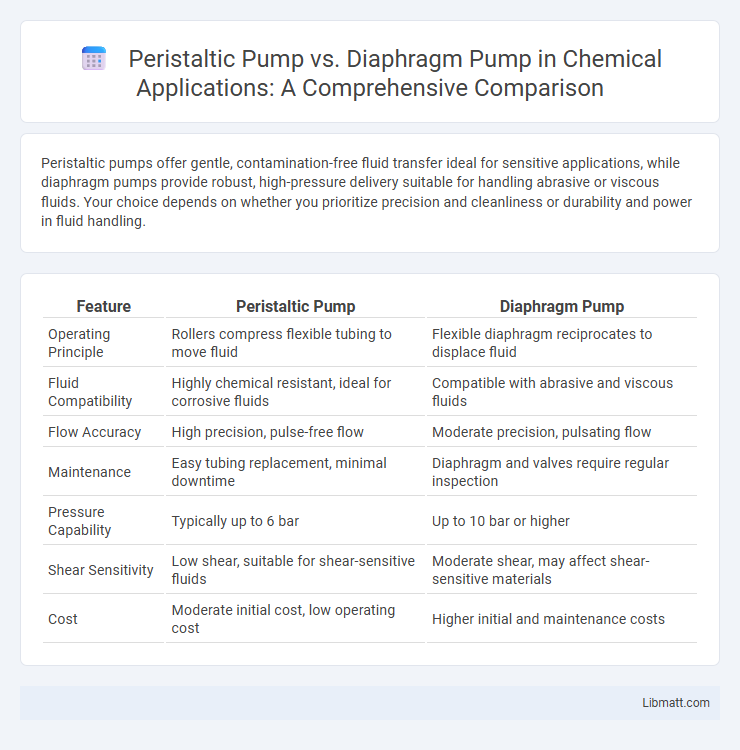

Peristaltic pumps offer gentle, contamination-free fluid transfer ideal for sensitive applications, while diaphragm pumps provide robust, high-pressure delivery suitable for handling abrasive or viscous fluids. Your choice depends on whether you prioritize precision and cleanliness or durability and power in fluid handling.

Table of Comparison

| Feature | Peristaltic Pump | Diaphragm Pump |

|---|---|---|

| Operating Principle | Rollers compress flexible tubing to move fluid | Flexible diaphragm reciprocates to displace fluid |

| Fluid Compatibility | Highly chemical resistant, ideal for corrosive fluids | Compatible with abrasive and viscous fluids |

| Flow Accuracy | High precision, pulse-free flow | Moderate precision, pulsating flow |

| Maintenance | Easy tubing replacement, minimal downtime | Diaphragm and valves require regular inspection |

| Pressure Capability | Typically up to 6 bar | Up to 10 bar or higher |

| Shear Sensitivity | Low shear, suitable for shear-sensitive fluids | Moderate shear, may affect shear-sensitive materials |

| Cost | Moderate initial cost, low operating cost | Higher initial and maintenance costs |

Introduction to Peristaltic and Diaphragm Pumps

Peristaltic pumps use rotating rollers to compress flexible tubing, creating a steady flow ideal for precise dosing and handling abrasive or viscous fluids without contamination. Diaphragm pumps employ a reciprocating diaphragm to generate suction and discharge, offering robust performance for applications involving chemically aggressive or shear-sensitive liquids. Your choice between these pumps depends on factors like fluid type, flow accuracy, and maintenance requirements.

How Peristaltic Pumps Work

Peristaltic pumps operate by compressing a flexible tube with rotating rollers or shoes, creating a vacuum that draws fluid through the tubing and pushes it forward in a controlled, pulsed flow. This design ensures that the fluid only contacts the interior of the tubing, preventing contamination and making peristaltic pumps ideal for sterile or aggressive fluids. The mechanical action generates minimal shear, preserving the integrity of sensitive liquids compared to diaphragm pumps that use a reciprocating diaphragm to create flow.

How Diaphragm Pumps Operate

Diaphragm pumps operate by flexing a diaphragm to create a variable volume chamber that draws in and expels fluid through check valves, ensuring precise and controlled flow. The reciprocating motion of the diaphragm generates suction and discharge strokes, making these pumps effective for handling viscous, corrosive, or abrasive fluids without damaging them. Your choice between peristaltic and diaphragm pumps depends on the application's fluid type, pressure requirements, and maintenance preferences, with diaphragm pumps offering robust performance in demanding environments.

Key Differences Between Peristaltic and Diaphragm Pumps

Peristaltic pumps use a rotating roller or shoe to compress flexible tubing, creating a smooth, pulsed flow ideal for handling abrasive or sterile fluids without contamination. Diaphragm pumps employ a reciprocating diaphragm to create suction and discharge, offering high pressure capabilities and excellent chemical resistance for viscous or aggressive fluids. Your choice depends on fluid type, pressure needs, and maintenance preferences, with peristaltic pumps excelling in gentle fluid handling and diaphragm pumps suited for higher pressure and tougher chemical environments.

Fluid Compatibility and Chemical Resistance

Peristaltic pumps excel in fluid compatibility and chemical resistance due to their tubing-based design, which isolates the fluid from pump components and allows handling of aggressive, abrasive, and viscous fluids without contamination. Diaphragm pumps offer robust chemical resistance, especially with elastomeric diaphragm materials like PTFE, making them suitable for corrosive and hazardous chemicals, but their wetted components may require careful selection based on fluid compatibility. The choice between peristaltic and diaphragm pumps hinges on the specific chemical properties of the fluid, system pressure, and maintenance considerations to optimize durability and performance.

Maintenance and Durability Comparison

Peristaltic pumps require minimal maintenance since the fluid only contacts the tubing, which can be easily replaced, reducing contamination risks and downtime. Diaphragm pumps, while robust and capable of handling abrasive or corrosive fluids, often need more frequent inspections due to diaphragm wear and potential seal failures. Durability in peristaltic pumps hinges on tubing material quality, whereas diaphragm pumps' lifespan depends on diaphragm integrity and valve condition, making maintenance schedules critical for both to ensure optimal reliability.

Accuracy and Flow Control

Peristaltic pumps offer precise flow control through adjustable tubing compression, allowing accurate dosing even with viscous or particulate-laden fluids. Diaphragm pumps provide excellent accuracy in pulsation-free delivery, with fine control achievable via stroke length and frequency adjustments. Both pump types ensure reliable metering, but peristaltic pumps excel in minimizing cross-contamination due to fluid isolation within the tubing.

Application Suitability: Which Industries Use Each?

Peristaltic pumps excel in industries such as pharmaceuticals, food and beverage, and wastewater treatment due to their gentle, contamination-free fluid handling and ability to pump viscous or shear-sensitive fluids. Diaphragm pumps are widely used in chemical processing, mining, and oil and gas sectors where robust, high-pressure pumping of aggressive or abrasive liquids is required. Your choice depends on the industry-specific needs for fluid compatibility, pressure, and maintenance considerations.

Cost Considerations and Operational Efficiency

Peristaltic pumps generally incur lower maintenance costs due to fewer moving parts contacting the fluid, while diaphragm pumps may have higher initial costs but offer better handling of abrasive or corrosive fluids, enhancing operational efficiency. Energy consumption in peristaltic pumps tends to be higher because of continuous tube compression, whereas diaphragm pumps often operate more efficiently with pulsation control. Selecting between the two depends on balancing upfront investment with ongoing maintenance expenses and the specific fluid handling requirements to optimize cost-effectiveness and performance.

Choosing the Right Pump: Factors to Consider

Selecting between a peristaltic pump and a diaphragm pump depends on your application's fluid type, pressure requirements, and maintenance preferences. Peristaltic pumps excel in handling shear-sensitive and corrosive liquids with minimal contamination risk, while diaphragm pumps provide higher pressure capabilities and handle viscous or abrasive fluids effectively. Assessing factors like flow rate accuracy, chemical compatibility, and ease of cleaning ensures you choose the optimal pump for your operational needs.

peristaltic pump vs diaphragm pump Infographic

libmatt.com

libmatt.com