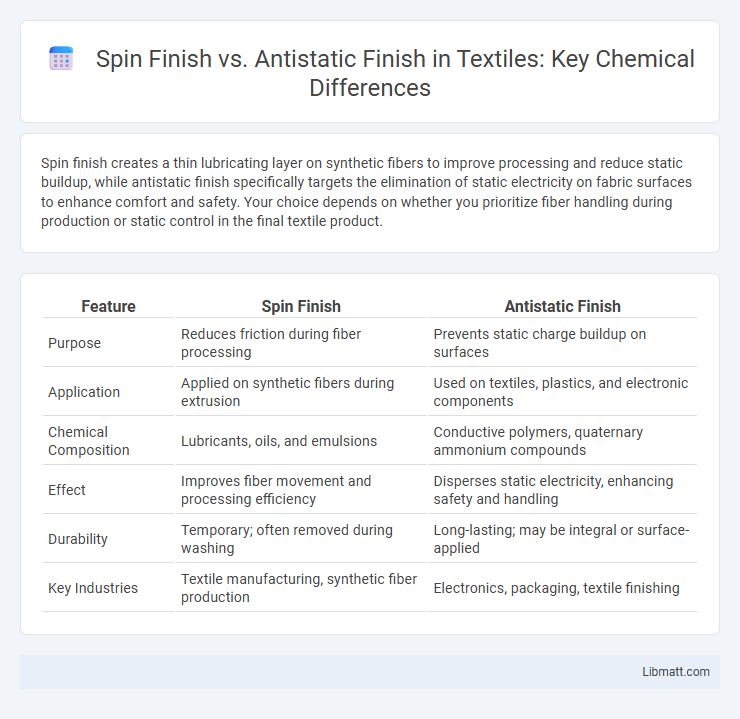

Spin finish creates a thin lubricating layer on synthetic fibers to improve processing and reduce static buildup, while antistatic finish specifically targets the elimination of static electricity on fabric surfaces to enhance comfort and safety. Your choice depends on whether you prioritize fiber handling during production or static control in the final textile product.

Table of Comparison

| Feature | Spin Finish | Antistatic Finish |

|---|---|---|

| Purpose | Reduces friction during fiber processing | Prevents static charge buildup on surfaces |

| Application | Applied on synthetic fibers during extrusion | Used on textiles, plastics, and electronic components |

| Chemical Composition | Lubricants, oils, and emulsions | Conductive polymers, quaternary ammonium compounds |

| Effect | Improves fiber movement and processing efficiency | Disperses static electricity, enhancing safety and handling |

| Durability | Temporary; often removed during washing | Long-lasting; may be integral or surface-applied |

| Key Industries | Textile manufacturing, synthetic fiber production | Electronics, packaging, textile finishing |

Introduction to Spin Finish and Antistatic Finish

Spin finish is a thin coating applied to synthetic fibers during manufacturing to enhance processing by reducing friction and static buildup. Antistatic finish, on the other hand, is a specialized treatment designed to minimize static electricity on textile surfaces, improving safety and comfort in various applications. Your choice between spin finish and antistatic finish depends on whether the priority is efficient fiber handling or static control in the final product.

Understanding Spin Finish in Textile Manufacturing

Spin finish in textile manufacturing involves applying a thin layer of lubricants or antistatic agents to synthetic fibers during the spinning process to enhance fiber handling and processing efficiency. This finish reduces friction, prevents static electricity buildup, and improves fiber cohesion, facilitating smoother weaving and knitting. Unlike antistatic finishes that primarily target static reduction post-production, spin finishes serve multiple functions including fiber lubrication and protection during early manufacturing stages.

Defining Antistatic Finish and Its Importance

Antistatic finish is a surface treatment applied to materials to reduce or eliminate static electricity buildup, which can cause dust attraction, static shocks, or damage to sensitive electronic components. This finish is crucial in industries such as electronics, textiles, and packaging where static control enhances product performance and safety. Compared to spin finish, which primarily lubricates fibers during manufacturing, antistatic finish specifically targets static charge prevention, improving material handling and end-use reliability.

Key Functions of Spin Finish in Fibers

Spin finish in fibers primarily serves as a lubricant and protectant to reduce friction during processing, enhancing fiber handling and preventing static buildup. It also improves fiber cohesion and eases downstream manufacturing processes such as spinning, weaving, and knitting. This finishing layer stabilizes fiber surface properties, contributing to consistent quality and performance in textile production.

Main Purposes of Antistatic Finish Applications

Antistatic finish applications primarily aim to reduce static electricity buildup on surfaces, preventing dust attraction and minimizing the risk of electrostatic discharge (ESD) that can damage electronic components. This finish enhances safety and product performance in industries like electronics, textiles, and packaging by improving conductivity or dissipating static charges. Unlike spin finish, which mainly facilitates fiber processing and lubrication, antistatic finishes ensure operational reliability and cleanliness in sensitive environments.

Spin Finish vs Antistatic Finish: Core Differences

Spin finish involves applying a lubricating coating to synthetic fibers to reduce friction during processing, enhancing fiber handling and durability. Antistatic finish, on the other hand, is designed to minimize static electricity buildup on textile surfaces, improving safety and comfort in end-use applications. Understanding these core differences helps you choose the appropriate finish based on whether fiber processing efficiency or static control is your primary concern.

Performance Comparison in Various Fiber Types

Spin finish provides superior lubrication and processing efficiency in synthetic fibers like polyester and nylon, enhancing filament surface smoothness and reducing breakage during textile manufacturing. Antistatic finish excels in natural fibers such as cotton and wool by minimizing static charge buildup, improving fabric handling, and reducing lint attraction in dry environments. In blended fibers, combining spin finish and antistatic agents optimizes both processing performance and static control, tailoring treatment to fiber composition and end-use requirements.

Impact on Fabric Processing and End-Use Properties

Spin finish enhances fiber lubrication and reduces static buildup during fabric processing, leading to smoother weaving and knitting operations while improving yarn strength and durability. Antistatic finish minimizes static electricity on finished fabrics, preventing clinging and electrostatic discharge, which is crucial for maintaining fabric comfort and safety in end-use applications. Both finishes optimize textile performance but target different stages: spin finish primarily aids in manufacturing efficiency, whereas antistatic finish improves consumer experience and product functionality.

Environmental and Safety Considerations

Spin finish typically involves applying lubricants and additives that can contain volatile organic compounds (VOCs), raising concerns about air quality and worker exposure during manufacturing and disposal processes. Antistatic finishes often use safer, water-based formulations with lower toxicity, thereby reducing environmental impact and minimizing health risks related to static discharge and chemical exposure. Choosing an antistatic finish with eco-friendly and non-toxic ingredients supports compliance with environmental regulations and promotes safer handling throughout the product lifecycle.

Choosing the Right Finish for Textile Applications

Choosing the right finish between spin finish and antistatic finish depends on your textile application's specific needs for friction reduction and static control. Spin finish enhances fiber processing by improving lubrication during spinning and weaving, which boosts production efficiency and fabric quality. Antistatic finish is essential for preventing static electricity buildup in synthetic textiles, ensuring safety, comfort, and material performance in electronic-sensitive or dust-prone environments.

Spin finish vs antistatic finish Infographic

libmatt.com

libmatt.com