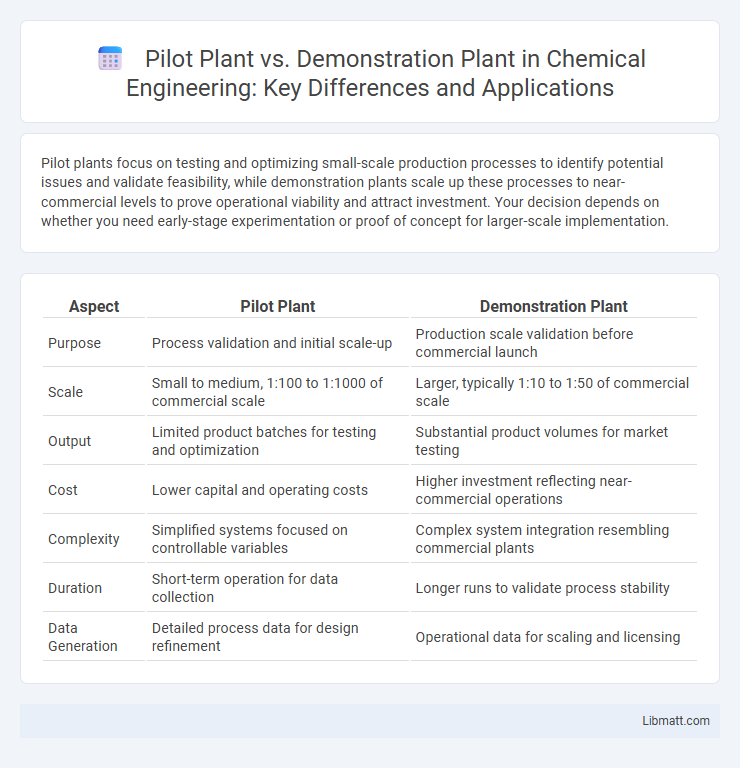

Pilot plants focus on testing and optimizing small-scale production processes to identify potential issues and validate feasibility, while demonstration plants scale up these processes to near-commercial levels to prove operational viability and attract investment. Your decision depends on whether you need early-stage experimentation or proof of concept for larger-scale implementation.

Table of Comparison

| Aspect | Pilot Plant | Demonstration Plant |

|---|---|---|

| Purpose | Process validation and initial scale-up | Production scale validation before commercial launch |

| Scale | Small to medium, 1:100 to 1:1000 of commercial scale | Larger, typically 1:10 to 1:50 of commercial scale |

| Output | Limited product batches for testing and optimization | Substantial product volumes for market testing |

| Cost | Lower capital and operating costs | Higher investment reflecting near-commercial operations |

| Complexity | Simplified systems focused on controllable variables | Complex system integration resembling commercial plants |

| Duration | Short-term operation for data collection | Longer runs to validate process stability |

| Data Generation | Detailed process data for design refinement | Operational data for scaling and licensing |

Introduction to Pilot Plants and Demonstration Plants

Pilot plants are small-scale industrial systems designed to test processes and generate data for scaling up, providing critical insights into operational feasibility and optimization. Demonstration plants operate at a larger scale than pilot plants, validating commercial viability and proving technology reliability under near-production conditions. Your choice between pilot and demonstration plants depends on the stage of development and the level of technical and economic validation required.

Defining Pilot Plants: Purpose and Scope

Pilot plants are small-scale industrial systems designed to test and validate the feasibility, safety, and performance of processes before full-scale production. They focus on optimizing process parameters, troubleshooting, and generating data to support scale-up decisions. The scope of pilot plants includes experimentation with raw materials, operational conditions, and equipment configurations to minimize risks and ensure process reliability.

Understanding Demonstration Plants: Key Characteristics

Demonstration plants are larger-scale facilities designed to validate the operational feasibility and economic viability of industrial processes before full commercial deployment. They typically operate continuously, producing significant quantities of product to simulate real-world conditions and provide data for scaling up. Key characteristics include advanced process control systems, comprehensive safety measures, and the ability to optimize and troubleshoot process parameters in an environment that closely resembles commercial production.

Key Differences Between Pilot and Demonstration Plants

Pilot plants focus on small-scale experimental processing to evaluate feasibility, analyze reaction kinetics, and optimize operational parameters before full-scale production. Demonstration plants operate at a larger scale to validate commercial viability, prove continuous processing, and generate data for economic and environmental assessments. Key differences include scale, purpose, operational continuity, and data reliability for market readiness.

Scale and Capacity Considerations

Pilot plants typically operate on a smaller scale with limited capacity, designed to test and optimize processes before full-scale production. Demonstration plants bridge the gap between pilot and commercial scales, offering larger capacity to validate process feasibility and economics under near-commercial conditions. Scale and capacity considerations determine equipment size, throughput, and data reliability for engineering scale-up decisions.

Objectives and Outcomes of Pilot vs. Demonstration Plants

Pilot plants are designed to evaluate the feasibility and optimize the process on a small scale, focusing on data collection, parameter testing, and preliminary performance assessment to reduce risks before scaling up. Demonstration plants aim to validate the technology under real operational conditions, bridging the gap between pilot studies and full-scale production by proving reliability, economic viability, and regulatory compliance. Outcomes of pilot plants include process design data and potential modifications, while demonstration plants provide evidence for commercial-scale implementation and attract investment.

Technology Validation: Pilot vs. Demonstration Stage

Pilot plants validate technology on a smaller scale to troubleshoot processes and optimize operational parameters before scaling up. Demonstration plants advance this validation by replicating commercial-scale conditions to confirm process reliability, product quality, and economic feasibility. Your decision between these stages impacts the depth of technology validation and the confidence level for full-scale production.

Investment and Operational Costs Comparison

Pilot plants typically require lower initial investment and operational costs due to their smaller scale and limited production capacity, making them ideal for early-stage process validation. Demonstration plants demand higher capital expenditure and operating expenses as they simulate larger-scale commercial operations to assess process scalability and economic feasibility. Cost differences reflect the distinct objectives of pilot plants for experimental data generation versus demonstration plants for comprehensive system testing and market readiness validation.

Real-world Examples of Pilot and Demonstration Plants

Pilot plants such as Tesla's battery recycling facility validate innovative lithium-ion recycling processes on a small scale to optimize efficiency and output before full-scale production. Demonstration plants like the Carbon Clean Solutions plant in India showcase the commercial viability of large-scale carbon capture technology, proving scalability and economic feasibility. These real-world examples highlight the transition from experimental validation to market-ready industrial operations in sectors like clean energy and advanced materials.

Choosing the Right Plant for Process Development

Selecting the right plant for process development hinges on project scale and objectives, with pilot plants offering small-scale testing to optimize reaction conditions and identify process variables efficiently. Demonstration plants simulate commercial production more closely, providing reliable data on economic feasibility, process reliability, and operational challenges. Your choice should balance cost, technical risk, and development timeline while ensuring scalability from pilot trials to full-scale manufacturing.

Pilot plant vs demonstration plant Infographic

libmatt.com

libmatt.com