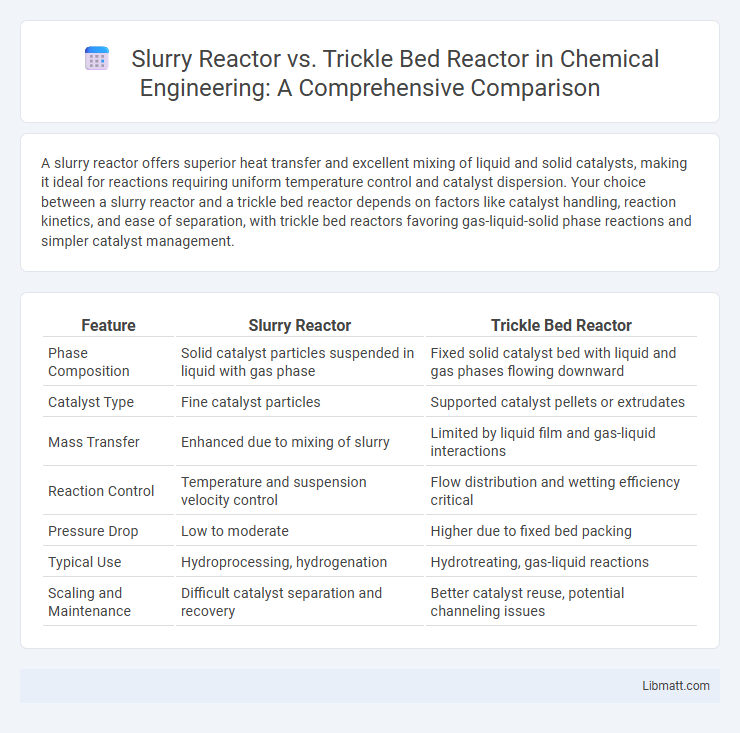

A slurry reactor offers superior heat transfer and excellent mixing of liquid and solid catalysts, making it ideal for reactions requiring uniform temperature control and catalyst dispersion. Your choice between a slurry reactor and a trickle bed reactor depends on factors like catalyst handling, reaction kinetics, and ease of separation, with trickle bed reactors favoring gas-liquid-solid phase reactions and simpler catalyst management.

Table of Comparison

| Feature | Slurry Reactor | Trickle Bed Reactor |

|---|---|---|

| Phase Composition | Solid catalyst particles suspended in liquid with gas phase | Fixed solid catalyst bed with liquid and gas phases flowing downward |

| Catalyst Type | Fine catalyst particles | Supported catalyst pellets or extrudates |

| Mass Transfer | Enhanced due to mixing of slurry | Limited by liquid film and gas-liquid interactions |

| Reaction Control | Temperature and suspension velocity control | Flow distribution and wetting efficiency critical |

| Pressure Drop | Low to moderate | Higher due to fixed bed packing |

| Typical Use | Hydroprocessing, hydrogenation | Hydrotreating, gas-liquid reactions |

| Scaling and Maintenance | Difficult catalyst separation and recovery | Better catalyst reuse, potential channeling issues |

Introduction to Slurry and Trickle Bed Reactors

Slurry reactors utilize a liquid-phase medium with suspended solid catalysts, promoting enhanced mass and heat transfer suitable for gas-liquid-solid reactions. Trickle bed reactors, in contrast, employ a fixed packed bed of solid catalysts with gas and liquid phases flowing simultaneously downward, optimizing surface contact and catalyst utilization. These reactors differ fundamentally in catalyst phase and flow dynamics, impacting their application in hydroprocessing and chemical synthesis.

Key Design Features of Slurry Reactors

Slurry reactors feature a suspension of solid catalyst particles within a liquid phase, enabling excellent heat transfer and mass diffusion for highly exothermic reactions. The design typically includes agitation systems to maintain catalyst dispersion and prevent settling, with reactor internals optimized for uniform flow distribution and temperature control. Operating conditions in slurry reactors allow fine control over catalyst particle size and residence time, enhancing reaction selectivity and conversion rates compared to trickle bed reactors.

Key Design Features of Trickle Bed Reactors

Trickle bed reactors feature a packed catalyst bed through which liquid and gas phases flow concurrently, optimizing gas-liquid-solid contact for enhanced catalytic reactions. The fixed-bed design facilitates efficient heat transfer and pressure drop management, making them ideal for hydroprocessing and hydrotreating applications. Compared to slurry reactors, trickle bed reactors offer simpler operation and lower catalyst attrition, though they may face challenges with mass transfer limitations and catalyst deactivation.

Mechanisms of Mass and Heat Transfer

Slurry reactors facilitate enhanced mass and heat transfer through the intimate contact between solid catalyst particles suspended in a liquid phase and the reactant gases or liquids, promoting high surface area and effective mixing. In contrast, trickle bed reactors rely on the downward flow of liquid over a packed bed of catalyst particles with gas flowing concurrently or counter-currently, where mass transfer is limited by liquid film resistance and gas-liquid interfacial area. Understanding these mechanisms is crucial for optimizing Your reaction rates, as slurry reactors typically offer superior heat removal and mass transfer efficiency compared to trickle bed reactors.

Catalyst Utilization and Management

Slurry reactors offer superior catalyst utilization by allowing continuous catalyst circulation and easier replacement, reducing deactivation and fouling issues common in trickle bed reactors. Trickle bed reactors rely on fixed catalyst beds, which can limit catalyst accessibility and create channeling, leading to uneven reactant distribution and less efficient catalyst use. Effective catalyst management in slurry reactors enhances process flexibility and longevity, while trickle bed reactors require frequent shutdowns for catalyst regeneration or replacement.

Operational Flexibility and Scale-Up

Slurry reactors offer superior operational flexibility due to their ability to handle varying catalyst types and particle sizes, accommodating diverse reaction conditions and feedstocks. Trickle bed reactors, while efficient for continuous gas-liquid-solid reactions, face challenges in scale-up because of limitations in liquid distribution and mass transfer rates. Your choice between the two depends on the specific process requirements, with slurry reactors generally preferred for processes needing adaptability and easier scale-up.

Typical Industrial Applications

Slurry reactors are widely used in Fischer-Tropsch synthesis for converting syngas into liquid hydrocarbons and in hydroprocessing for heavy oil upgrading due to their superior heat management and solid catalyst handling. Trickle bed reactors are favored in hydrotreating and hydrodesulfurization processes within refining industries because of their efficient gas-liquid-solid contact and simpler design. Your choice between these reactors depends on the specific reaction kinetics, catalyst properties, and scalability required in industrial applications.

Performance Comparison: Efficiency and Yield

Slurry reactors deliver higher mass transfer rates and improved heat management, resulting in enhanced reaction efficiency and higher product yield compared to trickle bed reactors. Trickle bed reactors exhibit limitations in catalyst wetting and fluid distribution, which can reduce overall conversion rates and selectivity. Optimizing slurry reactor conditions typically leads to superior performance for multiphase catalytic processes.

Challenges and Limitations

Slurry reactors face challenges such as catalyst separation difficulties and mass transfer limitations due to suspended particles, impacting reaction efficiency and operational costs. Trickle bed reactors encounter limitations like channeling, uneven liquid distribution, and pressure drop issues, which affect catalyst wettability and reaction uniformity. Your choice between these reactors should consider these operational constraints to optimize performance for specific chemical processes.

Future Trends and Innovations

Future trends in slurry reactors emphasize enhanced catalyst dispersion and improved mass transfer to boost reaction efficiency and selectivity, making them ideal for complex multiphase reactions. Trickle bed reactors are evolving with advanced packing materials and smart monitoring systems for optimized phase distribution and reduced channeling, increasing operational lifespan and reducing downtime. Your choice between these technologies will benefit from innovations like machine learning integration and novel catalyst development, driving higher productivity and energy efficiency in industrial applications.

Slurry reactor vs trickle bed reactor Infographic

libmatt.com

libmatt.com