Cage mills use rotating cages to crush material with minimal fines, making them ideal for sugar, salts, or soft materials, while hammer mills rely on high-speed hammers to pulverize material, producing finer particles suitable for feed and biomass processing. Choosing the right mill depends on the desired particle size, energy consumption, and material hardness, ensuring your processing demands are efficiently met.

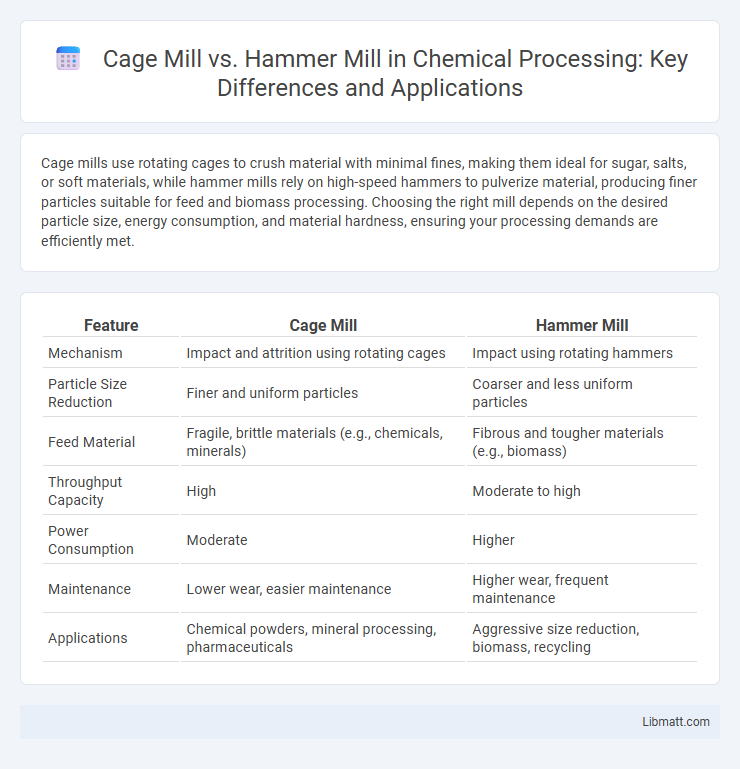

Table of Comparison

| Feature | Cage Mill | Hammer Mill |

|---|---|---|

| Mechanism | Impact and attrition using rotating cages | Impact using rotating hammers |

| Particle Size Reduction | Finer and uniform particles | Coarser and less uniform particles |

| Feed Material | Fragile, brittle materials (e.g., chemicals, minerals) | Fibrous and tougher materials (e.g., biomass) |

| Throughput Capacity | High | Moderate to high |

| Power Consumption | Moderate | Higher |

| Maintenance | Lower wear, easier maintenance | Higher wear, frequent maintenance |

| Applications | Chemical powders, mineral processing, pharmaceuticals | Aggressive size reduction, biomass, recycling |

Introduction to Cage Mill and Hammer Mill

Cage mills operate using a series of rotating cages that crush materials through impact and shear, ideal for size reduction of friable materials like coal and limestone. Hammer mills utilize a high-speed rotating shaft with swinging hammers to pulverize materials by impact, suited for milling grains, biomass, and recycling applications. Both mills emphasize efficient size reduction but differ in mechanism, energy consumption, and material adaptability.

Working Principles of Cage Mill

The working principle of a cage mill relies on high-speed rotating cage bars that impact and crush materials against a stationary breaker plate, producing uniform particle size reduction. Your material enters the mill and is subjected to repeated impacts from the rotating cage, which creates a tumbling motion and efficiently breaks down brittle and friable substances. This mechanism contrasts with hammer mills, where hammers swing to pulverize materials, making cage mills ideal for precision grinding and consistent output.

Working Principles of Hammer Mill

The working principle of a hammer mill involves the use of high-speed rotating hammers that impact and shatter materials into smaller pieces within a grinding chamber. Material enters the mill and is continuously crushed by the swinging hammers until it passes through a screen with specific hole sizes, determining the final particle size. This process is highly effective for grinding a wide range of materials, including grains, biomass, and minerals, providing consistent particle size distribution.

Key Design Differences

Cage mills feature rotors with cage bars that crush materials through shear and impact, while hammer mills use swinging hammers to pulverize feedstock by repeated impact forces. Cage mills typically operate at lower speeds, providing finer control over particle size distribution, whereas hammer mills run at higher speeds for rapid size reduction. The design difference also affects wear patterns; cage bars in cage mills experience less abrasion compared to hammer mill hammers, influencing maintenance cycles and operational efficiency.

Material Size Reduction Capabilities

Cage mills provide precise material size reduction through low-impact shearing and crushing, ideal for achieving consistent particle sizes in fine to medium grinding applications. Hammer mills deliver high-impact size reduction by rapidly swinging hammers, efficiently breaking down materials into coarse to medium sizes, suitable for fibrous or abrasive raw inputs. Each mill type optimizes output particle size distribution differently, depending on feed material properties and desired end-use specifications.

Energy Efficiency Comparison

Cage mills exhibit higher energy efficiency compared to hammer mills due to their attrition grinding mechanism, which consumes less power by applying shear forces rather than repeated impact. Hammer mills typically require more energy because the hammers must repeatedly strike materials at high speeds to achieve size reduction. Studies indicate cage mills can reduce energy consumption by up to 20-30% in fine grinding applications, making them preferable where power savings are critical.

Typical Applications and Industries

Cage mills and hammer mills serve distinct roles in material size reduction across various industries. Cage mills are commonly used in recycling, coal pulverizing, and food processing for controlled particle size and minimal fines, making them ideal for applications requiring gentle crushing. Hammer mills excel in agriculture, biomass, and pharmaceuticals by delivering rapid, high-impact grinding suitable for feed production and material pulverization, ensuring your processing needs are met efficiently.

Maintenance and Operating Costs

Cage mills generally require lower maintenance costs due to fewer moving parts and reduced wear rates on cage bars compared to the hammer tips in hammer mills, which frequently need replacement and regular lubrication. Operating costs for cage mills are often more economical because their energy consumption is typically lower, enhancing overall cost efficiency in continuous processing environments. Conversely, hammer mills may incur higher downtime and labor expenses associated with routine inspections and repairs driven by their higher mechanical stress and material impact levels.

Advantages and Disadvantages

Cage mills offer precise size control and produce less heat during operation, making them ideal for fine grinding of abrasive materials but have lower throughput compared to hammer mills. Hammer mills provide higher capacity and are more cost-effective for coarse grinding, though they generate more heat and noise, which can affect material quality and operator comfort. Maintenance for cage mills tends to be more complex and costly, whereas hammer mills require frequent hammer replacements but are easier to service.

Choosing the Right Mill for Your Process

Selecting between a Cage mill and a Hammer mill depends on the material hardness, particle size requirements, and desired throughput. Cage mills excel in producing uniform fines and handling sticky or fibrous materials, offering low maintenance and noise levels. Hammer mills deliver higher capacity and are effective for coarse grinding of tough materials but require more frequent wear part replacements and generate higher noise.

Cage mill vs hammer mill Infographic

libmatt.com

libmatt.com