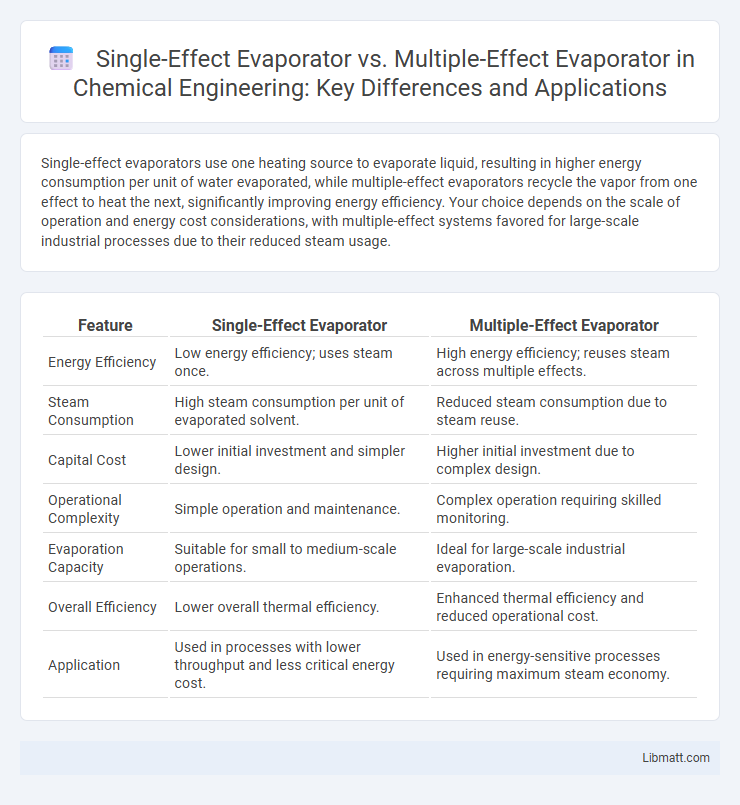

Single-effect evaporators use one heating source to evaporate liquid, resulting in higher energy consumption per unit of water evaporated, while multiple-effect evaporators recycle the vapor from one effect to heat the next, significantly improving energy efficiency. Your choice depends on the scale of operation and energy cost considerations, with multiple-effect systems favored for large-scale industrial processes due to their reduced steam usage.

Table of Comparison

| Feature | Single-Effect Evaporator | Multiple-Effect Evaporator |

|---|---|---|

| Energy Efficiency | Low energy efficiency; uses steam once. | High energy efficiency; reuses steam across multiple effects. |

| Steam Consumption | High steam consumption per unit of evaporated solvent. | Reduced steam consumption due to steam reuse. |

| Capital Cost | Lower initial investment and simpler design. | Higher initial investment due to complex design. |

| Operational Complexity | Simple operation and maintenance. | Complex operation requiring skilled monitoring. |

| Evaporation Capacity | Suitable for small to medium-scale operations. | Ideal for large-scale industrial evaporation. |

| Overall Efficiency | Lower overall thermal efficiency. | Enhanced thermal efficiency and reduced operational cost. |

| Application | Used in processes with lower throughput and less critical energy cost. | Used in energy-sensitive processes requiring maximum steam economy. |

Introduction to Evaporators

Single-effect evaporators utilize a single heating source to evaporate liquid, resulting in higher energy consumption compared to multiple-effect evaporators, which reuse vapor from one effect as the heating source for the next, significantly improving energy efficiency. The design of single-effect evaporators is simpler and cost-effective for small-scale applications, while multiple-effect evaporators are preferred in large-scale industrial processes due to their reduced steam requirement and operational cost. Understanding the difference in heat utilization and capacity is essential for selecting the appropriate evaporator for food processing, chemical manufacturing, and wastewater treatment industries.

Overview of Single-Effect Evaporators

Single-effect evaporators operate by using steam to heat a solution, causing the solvent to evaporate and separate from the solute in a single stage. This technology is simpler and requires less initial investment but consumes more energy per unit of solvent evaporated compared to multiple-effect evaporators. Your choice of a single-effect evaporator is ideal for small-scale operations where lower capital costs and simpler design outweigh energy efficiency concerns.

Overview of Multiple-Effect Evaporators

Multiple-effect evaporators enhance energy efficiency by using steam from one effect to heat the next, significantly reducing overall steam consumption compared to single-effect evaporators. They consist of a series of evaporators operating at progressively lower pressures, allowing vapor generated in one effect to serve as the heating medium for the following effect. This design optimizes fuel usage and lowers operational costs in industrial processes such as chemical manufacturing, desalination, and food processing.

Principle of Operation: Single vs. Multiple-Effect

A single-effect evaporator operates by using steam to heat the liquid once, causing evaporation in a single stage, which results in higher energy consumption. Multiple-effect evaporators utilize the vapor generated from one effect as the heating medium for the next effect, leveraging successive stages to reduce overall steam usage and improve thermal efficiency. This cascading principle significantly lowers fuel costs and enhances productivity in industrial applications by reusing energy across multiple effects.

Energy Efficiency Comparison

Multiple-effect evaporators significantly outperform single-effect evaporators in energy efficiency by reusing steam across several stages, reducing overall steam consumption by up to 60-70%. Single-effect evaporators consume more steam per unit of evaporated water, making them less cost-effective for large-scale operations. Your process can achieve substantial energy savings and lower operational costs by opting for multiple-effect evaporators in continuous or large-volume evaporation tasks.

Installation and Operational Costs

Single-effect evaporators have lower initial installation costs due to their simpler design and fewer components, making them suitable for small-scale operations. Multiple-effect evaporators, while requiring higher upfront investment for complex setup and larger equipment, significantly reduce operational costs by recycling steam across multiple effects, achieving greater energy efficiency. The choice between these systems depends on balancing capital expenditure against long-term savings in fuel and operational expenses.

Applications in Various Industries

Single-effect evaporators are commonly used in industries requiring low capital investment and moderate energy efficiency, such as pharmaceuticals, food processing, and small-scale chemical manufacturing. Multiple-effect evaporators find extensive application in industries with high production volumes and stringent energy-saving requirements, including pulp and paper, sugar refining, and large-scale wastewater treatment plants. Their ability to reuse steam across multiple stages significantly reduces operational costs and enhances production capacity in heavy industrial processes.

Advantages and Disadvantages

A single-effect evaporator offers simplicity, lower initial cost, and easier maintenance but consumes more steam, resulting in higher operating expenses. Multiple-effect evaporators significantly improve energy efficiency by reusing steam across stages, reducing fuel consumption and overall costs, but involve higher capital investment and complex operation. Your choice depends on factors like production scale, energy costs, and budget constraints.

Factors Influencing Choice of Evaporator

The choice between a single-effect evaporator and a multiple-effect evaporator depends primarily on factors such as energy efficiency, feed concentration, and operational costs. Multiple-effect evaporators offer greater energy savings by reusing steam across effects, making them ideal for high-capacity, continuous operations with concentrated feeds. Your decision should also consider maintenance complexity and initial investment, with single-effect evaporators being simpler and more cost-effective for smaller-scale or low-concentration processes.

Summary and Final Recommendations

Single-effect evaporators use one heating source and are suitable for smaller-scale operations with lower energy efficiency, while multiple-effect evaporators utilize multiple stages to conserve steam and significantly reduce energy consumption in large-scale industrial processes. The choice depends on operational cost, scale, and efficiency requirements, with multiple-effect evaporators offering superior energy savings and throughput for high-volume applications. For optimal performance and cost-efficiency, industries handling large liquid volumes should prioritize multiple-effect evaporators despite higher initial investment.

single-effect evaporator vs multiple-effect evaporator Infographic

libmatt.com

libmatt.com