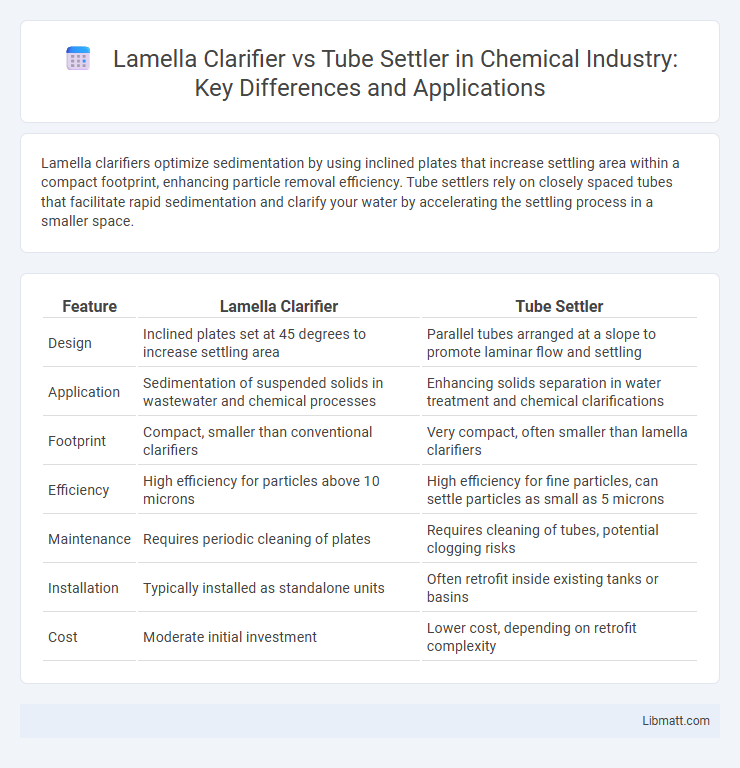

Lamella clarifiers optimize sedimentation by using inclined plates that increase settling area within a compact footprint, enhancing particle removal efficiency. Tube settlers rely on closely spaced tubes that facilitate rapid sedimentation and clarify your water by accelerating the settling process in a smaller space.

Table of Comparison

| Feature | Lamella Clarifier | Tube Settler |

|---|---|---|

| Design | Inclined plates set at 45 degrees to increase settling area | Parallel tubes arranged at a slope to promote laminar flow and settling |

| Application | Sedimentation of suspended solids in wastewater and chemical processes | Enhancing solids separation in water treatment and chemical clarifications |

| Footprint | Compact, smaller than conventional clarifiers | Very compact, often smaller than lamella clarifiers |

| Efficiency | High efficiency for particles above 10 microns | High efficiency for fine particles, can settle particles as small as 5 microns |

| Maintenance | Requires periodic cleaning of plates | Requires cleaning of tubes, potential clogging risks |

| Installation | Typically installed as standalone units | Often retrofit inside existing tanks or basins |

| Cost | Moderate initial investment | Lower cost, depending on retrofit complexity |

Introduction to Lamella Clarifier and Tube Settler

Lamella clarifiers utilize inclined plates to increase settling surface area, promoting rapid sedimentation in wastewater treatment. Tube settlers consist of parallel, closely spaced tubes that enhance particle settling by reducing the settling distance and preventing turbidity. Both systems optimize solid-liquid separation but differ in design and application efficiency for clarifying water.

Principles of Operation: Lamella Clarifier vs Tube Settler

Lamella clarifiers operate by allowing water to flow through a series of inclined plates, increasing the settling area and reducing the footprint for sedimentation. Tube settlers use parallel, closely spaced tubes that create a large surface area for particle settling, enhancing sedimentation efficiency in a compact design. Both systems improve solid-liquid separation by encouraging laminar flow and minimizing turbulence, but lamella clarifiers typically handle larger volumes with a more robust settling mechanism.

Key Design Differences

Lamella clarifiers utilize inclined plates to increase the settling area within a compact footprint, making them highly efficient for sedimentation in wastewater treatment. Tube settlers consist of a series of parallel tubes that enhance settling by creating laminar flow, resulting in quicker particle removal compared to conventional clarifiers. Your choice between the two depends on factors such as available space, flow rate, and the nature of suspended solids in the water.

Space and Footprint Requirements

Lamella clarifiers require more vertical space due to their inclined plates but occupy a smaller horizontal footprint compared to traditional clarifiers. Tube settlers offer a compact design with a reduced footprint, making them ideal for facilities with limited space. Your choice depends on balancing available site dimensions with treatment capacity needs.

Efficiency and Performance Comparison

Lamella clarifiers achieve higher efficiency in settling fine particles due to their inclined plates that increase the effective settling area, enabling faster sedimentation rates compared to tube settlers. Tube settlers offer superior performance in treating high flow rates and handling variable loading by providing modular design and uniform flow distribution but may require larger footprint and maintenance. Overall, lamella clarifiers outperform tube settlers in compact installations with consistent flow, while tube settlers excel in flexibility and operational adaptability.

Installation and Maintenance Considerations

Lamella clarifiers require precise angle installation of inclined plates to maximize sedimentation efficiency, demanding careful alignment during setup. Tube settlers feature modular, easily replaceable components, allowing quicker maintenance and lower downtime compared to the fixed plates of lamella clarifiers. Your choice depends on available space, installation complexity, and the ease of routine cleaning in your specific water treatment application.

Suitability for Different Water Treatment Applications

Lamella clarifiers are highly suitable for municipal and industrial water treatment where large volumes require efficient sedimentation due to their compact design and high surface area. Tube settlers excel in applications with varying flow rates and suspended solids, offering flexibility and enhanced settling performance in wastewater and stormwater treatment. Your choice depends on the specific water quality, flow conditions, and space constraints of the treatment facility.

Cost Analysis: Initial and Operational Expenses

Lamella clarifiers typically have higher initial costs due to complex fabrication and installation of inclined plates, while tube settlers offer more cost-effective setups with modular designs. Operational expenses favor tube settlers as they require less maintenance and consume less energy for sludge removal and cleaning. Evaluating total cost of ownership involves balancing the upfront investment of lamella clarifiers against the lower ongoing expenses associated with tube settlers.

Advantages and Disadvantages of Each System

Lamella clarifiers offer a compact design with high surface area for sedimentation, enabling efficient removal of fine particles and reduced footprint compared to conventional clarifiers, but they can be prone to clogging and require regular maintenance. Tube settlers provide enhanced settling efficiency through inclined parallel plates that accelerate particle settling, allowing for increased flow rates and better handling of variations in influent quality, yet their installation can be complex and they are less effective with highly flocculated or sticky solids. Both systems improve sedimentation rates, but lamella clarifiers excel in space-saving applications, while tube settlers are preferred for variable load conditions and ease of retrofit.

Choosing the Right Solution for Your Facility

Lamella clarifiers offer high-capacity sedimentation by using inclined plates that increase settling area, making them ideal for facilities with limited footprint but high flow rates. Tube settlers provide efficient particle removal through modular, easy-to-maintain units, suitable for facilities requiring flexible, scalable designs. Assess your facility's space constraints, flow characteristics, and maintenance capabilities to determine the optimal choice for maximizing water treatment efficiency.

lamella clarifier vs tube settler Infographic

libmatt.com

libmatt.com