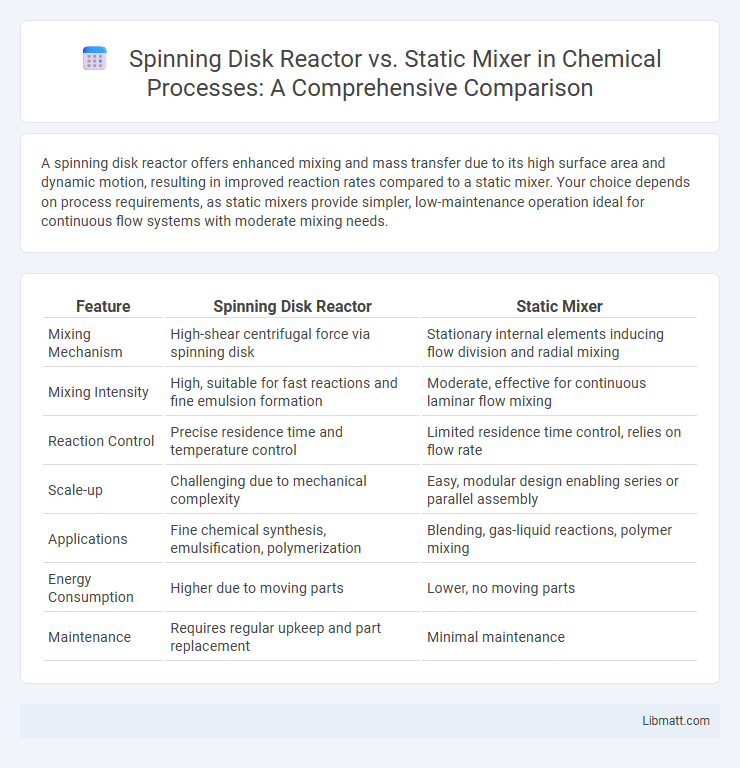

A spinning disk reactor offers enhanced mixing and mass transfer due to its high surface area and dynamic motion, resulting in improved reaction rates compared to a static mixer. Your choice depends on process requirements, as static mixers provide simpler, low-maintenance operation ideal for continuous flow systems with moderate mixing needs.

Table of Comparison

| Feature | Spinning Disk Reactor | Static Mixer |

|---|---|---|

| Mixing Mechanism | High-shear centrifugal force via spinning disk | Stationary internal elements inducing flow division and radial mixing |

| Mixing Intensity | High, suitable for fast reactions and fine emulsion formation | Moderate, effective for continuous laminar flow mixing |

| Reaction Control | Precise residence time and temperature control | Limited residence time control, relies on flow rate |

| Scale-up | Challenging due to mechanical complexity | Easy, modular design enabling series or parallel assembly |

| Applications | Fine chemical synthesis, emulsification, polymerization | Blending, gas-liquid reactions, polymer mixing |

| Energy Consumption | Higher due to moving parts | Lower, no moving parts |

| Maintenance | Requires regular upkeep and part replacement | Minimal maintenance |

Introduction to Spinning Disk Reactors and Static Mixers

Spinning disk reactors utilize high-speed rotating disks to generate intense mixing and enhance mass transfer, making them ideal for fast chemical reactions and processes requiring uniform heat distribution. Static mixers consist of stationary mixing elements within a pipe that continuously blend fluids through turbulent flow without moving parts, ensuring low maintenance and consistent mixing performance. Both technologies optimize mixing efficiency but differ significantly in mechanical complexity and energy consumption.

Principle of Operation: Spinning Disk Reactors

Spinning disk reactors operate on the principle of creating intense shear and rapid mixing by rotating a disk at high speeds, which generates thin liquid films and enhances mass and heat transfer rates. This mechanism significantly improves reaction kinetics and uniformity compared to static mixers, where mixing relies on passive flow disruption without mechanical movement. Your processes benefit from the enhanced contact efficiency and scalable design of spinning disk reactors for fast, controlled chemical reactions.

Principle of Operation: Static Mixers

Static mixers operate by channeling fluid through fixed, internal elements that create turbulence and blend components efficiently without moving parts. This principle of operation relies on continuous division, radial mixing, and reorientation of fluid layers to achieve homogeneous mixing. Your process benefits from the simplicity and low maintenance of static mixers, making them ideal for steady-state operations with viscous or multiphase fluids.

Key Applications in Chemical Processing

Spinning disk reactors are highly effective for fast, controlled mixing and heat transfer in high-throughput chemical synthesis, such as polymerization and fine chemical production. Static mixers excel in continuous flow processes requiring efficient mixing without moving parts, commonly used for blending, emulsification, and gas-liquid reactions. Your choice depends on process scale, mixing intensity, and reaction kinetics, with spinning disk reactors offering rapid mass transfer and static mixers providing reliable, maintenance-free operation.

Mixing Efficiency Comparison

Spinning disk reactors achieve superior mixing efficiency through high turbulence and rapid radial mixing, significantly enhancing mass transfer rates compared to static mixers. Static mixers rely on flow division and recombination, resulting in moderate mixing efficiency suitable for laminar flow conditions but less effective for highly viscous fluids or fast reactions. The intensified mixing in spinning disk reactors reduces reaction time and improves product uniformity, making them optimal for processes requiring precise and rapid mixing.

Mass Transfer Performance Analysis

Spinning disk reactors exhibit superior mass transfer performance compared to static mixers due to their high surface area and intense micromixing capabilities, which enhance interfacial contact between phases. The centrifugal forces generated by the rotating disk promote rapid dispersion and reduced mass transfer resistance, improving reaction rates significantly. Optimizing your process with a spinning disk reactor can lead to higher efficiency in mixing-sensitive reactions and better scalable mass transfer performance.

Scale-Up Potential and Flexibility

Spinning disk reactors offer significant scale-up potential due to their high mass transfer rates and efficient mixing, which maintain performance consistency across various production volumes. Static mixers provide flexibility in flow rates and can be easily integrated into existing pipeline systems, but may face limitations in scale-up due to reduced mixing efficiency at larger diameters. Your choice depends on whether you prioritize scalability with uniform reaction conditions (spinning disk reactor) or process adaptability and installation simplicity (static mixer).

Energy Consumption and Operational Costs

Spinning disk reactors typically consume more energy due to the high rotational speeds required to achieve efficient mixing, which can increase your operational costs. In contrast, static mixers rely on the flow of liquids passing through fixed elements, resulting in lower energy consumption and reduced expenses over time. Choosing between these technologies depends on balancing the intensity of mixing needed against the impact on your energy budget and overall costs.

Maintenance and Design Considerations

Spinning disk reactors feature rotating elements that require regular maintenance to prevent wear and ensure consistent performance, while static mixers have no moving parts, resulting in lower maintenance demands and simpler design. The complexity of spinning disk reactors necessitates precise alignment and balance, increasing design intricacy compared to the straightforward, modular construction of static mixers. Material selection in spinning disk reactors is critical to withstand mechanical stresses, whereas static mixers prioritize corrosion resistance and ease of cleaning.

Choosing the Right Reactor for Your Application

When choosing the right reactor for your application, consider that spinning disk reactors offer superior mass transfer and enhanced mixing efficiency, ideal for fast, multiphase reactions. Static mixers provide a cost-effective solution for continuous-flow processes with lower energy consumption and simpler maintenance requirements. Your decision should balance reaction kinetics, scale, and operational complexity to optimize performance and product quality.

spinning disk reactor vs static mixer Infographic

libmatt.com

libmatt.com