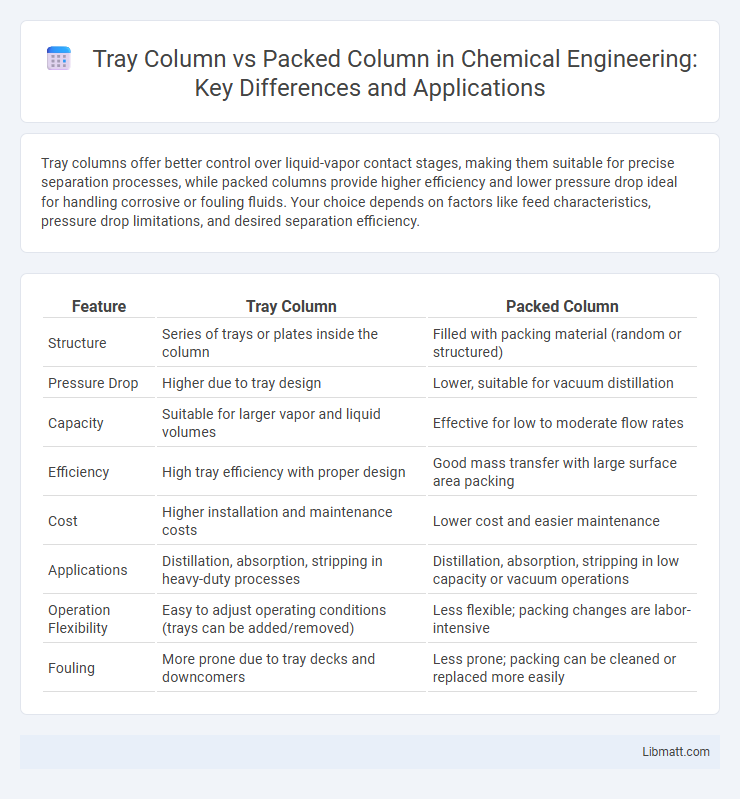

Tray columns offer better control over liquid-vapor contact stages, making them suitable for precise separation processes, while packed columns provide higher efficiency and lower pressure drop ideal for handling corrosive or fouling fluids. Your choice depends on factors like feed characteristics, pressure drop limitations, and desired separation efficiency.

Table of Comparison

| Feature | Tray Column | Packed Column |

|---|---|---|

| Structure | Series of trays or plates inside the column | Filled with packing material (random or structured) |

| Pressure Drop | Higher due to tray design | Lower, suitable for vacuum distillation |

| Capacity | Suitable for larger vapor and liquid volumes | Effective for low to moderate flow rates |

| Efficiency | High tray efficiency with proper design | Good mass transfer with large surface area packing |

| Cost | Higher installation and maintenance costs | Lower cost and easier maintenance |

| Applications | Distillation, absorption, stripping in heavy-duty processes | Distillation, absorption, stripping in low capacity or vacuum operations |

| Operation Flexibility | Easy to adjust operating conditions (trays can be added/removed) | Less flexible; packing changes are labor-intensive |

| Fouling | More prone due to tray decks and downcomers | Less prone; packing can be cleaned or replaced more easily |

Introduction to Tray Columns and Packed Columns

Tray columns and packed columns are essential types of equipment used for gas-liquid contact in chemical processing, particularly in distillation and absorption. Tray columns use multiple horizontal trays to hold liquid layers, promoting vapor-liquid interaction, while packed columns contain a bed of packing material providing a large surface area for mass transfer. Your choice between these columns depends on factors such as capacity, pressure drop, and separation efficiency.

Fundamental Differences Between Tray and Packed Columns

Tray columns use perforated trays to enhance vapor-liquid contact by creating discrete stages, while packed columns rely on random or structured packing materials that provide continuous surface area for mass transfer. The fundamental difference lies in tray columns offering stagewise separation with clear vapor-liquid equilibrium stages, whereas packed columns facilitate a more flexible, often lower-pressure drop operation through continuous contact. Your choice depends on factors like capacity, pressure drop, and separation efficiency required in the specific industrial process.

Design and Construction Features

Tray columns utilize horizontal trays or plates that create stages for vapor-liquid contact, often featuring bubble caps, valves, or sieve plates designed for precise control of vapor flow and liquid distribution. Packed columns consist of a vertical shell filled with packing materials such as random or structured packing, which maximize surface area for mass transfer without discrete stages, promoting continuous vapor-liquid interaction. Tray columns generally allow easier maintenance and flexibility in operation, while packed columns offer lower pressure drop and better efficiency for certain applications, influencing their design and construction choices significantly.

Operating Principles of Tray Columns

Tray columns operate by allowing vapor to rise through trays where liquid flows across each tray, promoting mass transfer through intimate vapor-liquid contact. Each tray acts as a stage where vapor and liquid phases reach equilibrium, enhancing separation efficiency based on component volatilities. Your choice of tray column depends on factors like capacity, pressure drop, and ease of maintenance compared to packed columns.

Operating Principles of Packed Columns

Packed columns operate by allowing vapor and liquid phases to flow countercurrently through a column filled with packing material, which provides a large surface area for mass transfer and facilitates efficient contact between phases. The liquid flows down over the packing while vapor rises, enabling vapor-liquid equilibrium stages that enhance separation based on differences in volatility. Pressure drop, liquid holdup, and mass transfer efficiency are critical parameters influencing the operating performance of packed columns in distillation or absorption processes.

Key Performance Metrics Comparison

Tray columns exhibit higher efficiency in vapor-liquid contact due to discrete stage separation, enabling better mass transfer under varying operational conditions. Packed columns, with their continuous packing material, offer lower pressure drop and increased capacity, making them suitable for handling large vapor and liquid flow rates. Key performance metrics indicate tray columns excel in precise separation tasks, while packed columns optimize energy usage and throughput in large-scale industrial applications.

Advantages of Tray Columns

Tray columns offer superior vapor-liquid contact efficiency, enabling precise control over separation processes in distillation applications. Their design facilitates easy inspection, maintenance, and adaptability to fluctuating operating conditions, enhancing operational reliability. Tray columns also handle a wide range of feed compositions and flow rates, making them versatile choices for chemical and petrochemical industries.

Advantages of Packed Columns

Packed columns offer higher surface area for vapor-liquid contact, enhancing mass transfer efficiency compared to tray columns. They require lower pressure drops, which can reduce energy consumption in your distillation or absorption processes. Maintenance and operational costs tend to be lower due to fewer mechanical parts and simpler design, making packed columns advantageous in many chemical engineering applications.

Typical Industrial Applications

Tray columns are commonly used in oil refining and large-scale chemical processes where precise control over vapor-liquid contact and ease of maintenance are crucial. Packed columns excel in smaller-scale applications such as natural gas absorption, solvent recovery, and air pollution control due to their lower pressure drop and handling of corrosive or fouling mixtures. Choosing between the two depends on Your process requirements, including capacity, separation efficiency, and operational complexity.

Selection Criteria: Choosing the Right Column

Selection between tray columns and packed columns depends on factors like capacity, pressure drop, and separation efficiency. Tray columns are preferred for large-scale operations with high capacity and easier flooding control, while packed columns are suitable for smaller capacity and low-pressure drop requirements. Your choice should consider feed characteristics, column diameter, and maintenance needs for optimal separation performance.

Tray column vs packed column Infographic

libmatt.com

libmatt.com