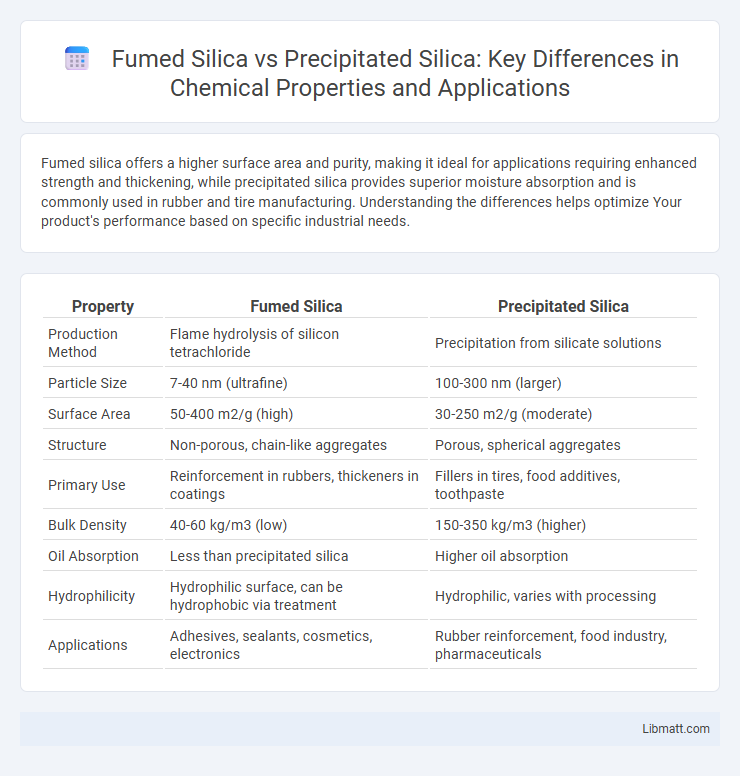

Fumed silica offers a higher surface area and purity, making it ideal for applications requiring enhanced strength and thickening, while precipitated silica provides superior moisture absorption and is commonly used in rubber and tire manufacturing. Understanding the differences helps optimize Your product's performance based on specific industrial needs.

Table of Comparison

| Property | Fumed Silica | Precipitated Silica |

|---|---|---|

| Production Method | Flame hydrolysis of silicon tetrachloride | Precipitation from silicate solutions |

| Particle Size | 7-40 nm (ultrafine) | 100-300 nm (larger) |

| Surface Area | 50-400 m2/g (high) | 30-250 m2/g (moderate) |

| Structure | Non-porous, chain-like aggregates | Porous, spherical aggregates |

| Primary Use | Reinforcement in rubbers, thickeners in coatings | Fillers in tires, food additives, toothpaste |

| Bulk Density | 40-60 kg/m3 (low) | 150-350 kg/m3 (higher) |

| Oil Absorption | Less than precipitated silica | Higher oil absorption |

| Hydrophilicity | Hydrophilic surface, can be hydrophobic via treatment | Hydrophilic, varies with processing |

| Applications | Adhesives, sealants, cosmetics, electronics | Rubber reinforcement, food industry, pharmaceuticals |

Introduction to Fumed Silica and Precipitated Silica

Fumed silica is a high-purity, amorphous silicon dioxide produced by flame hydrolysis of silicon tetrachloride, resulting in a fine, low-density powder with high surface area and excellent thixotropic properties. Precipitated silica is synthesized through the precipitation of sodium silicate with acid, yielding a granular, porous material commonly used as a reinforcing filler and anti-caking agent. Both forms of silica find extensive applications in rubber, coatings, adhesives, and cosmetics, with distinct physical characteristics tailored to specific industrial uses.

Chemical Composition and Manufacturing Processes

Fumed silica is produced through the flame hydrolysis of silicon tetrachloride, resulting in a highly pure, amorphous silicon dioxide with a surface area typically ranging from 50 to 400 m2/g. Precipitated silica is manufactured by the neutralization of sodium silicate with acid, forming aggregates of silicon dioxide with a surface area generally between 40 and 200 m2/g. Both consist primarily of SiO2 but differ in particle size, surface morphology, and production method, influencing their application in industries like rubber, cosmetics, and adhesives.

Physical Properties Comparison

Fumed silica exhibits a lower bulk density (about 50-100 kg/m3) compared to precipitated silica (150-300 kg/m3) due to its highly porous, nanoscale structure composed of aggregated primary particles. The surface area of fumed silica ranges from 50 to 400 m2/g, significantly higher than precipitated silica, which typically presents 50 to 300 m2/g, resulting in enhanced thixotropic properties and haze control in applications. Particle morphology differs as well; fumed silica has a chain-like, branched primary particle structure, whereas precipitated silica consists of more spherical and less aggregated particles, affecting dispersion and rheology in formulations.

Particle Size and Surface Area Differences

Fumed silica particles are ultra-fine, typically ranging from 7 to 40 nanometers, with a high surface area of 200 to 400 m2/g, resulting in superior thickening and reinforcing properties. Precipitated silica particles are larger, generally between 5 to 100 micrometers, and possess a lower surface area around 50 to 300 m2/g, offering different absorption and compounding characteristics. Understanding these particle size and surface area differences helps optimize Your product formulation for enhanced performance and stability.

Key Applications in Various Industries

Fumed silica is widely used in industries requiring high-purity and low-moisture content, such as pharmaceuticals, cosmetics, and electronics, providing thickening, anti-caking, and reinforcing properties. Precipitated silica's larger particle size and higher moisture content make it ideal for rubber reinforcement, tire manufacturing, toothpaste formulation, and food additives. Your choice between fumed and precipitated silica depends on specific application needs like surface area, purity, and moisture content to optimize performance.

Performance in Reinforcement and Thickening

Fumed silica offers superior reinforcement in rubber and silicone applications due to its high surface area and small particle size, enhancing tensile strength and abrasion resistance significantly more than precipitated silica. Precipitated silica excels as a thickening agent in adhesives, coatings, and sealants, providing excellent viscosity control and thixotropic properties that improve processing and stability. The choice between fumed and precipitated silica depends on the specific performance requirements, with fumed silica preferred for mechanical reinforcement and precipitated silica favored for viscosity modification and rheological control.

Dispersion and Compatibility in Formulations

Fumed silica exhibits superior dispersion and compatibility in formulations due to its ultrafine particle size and high surface area, which enhance stability and rheological properties. Precipitated silica, while effective as a thickening agent, tends to aggregate more easily, resulting in less uniform dispersion and potential compatibility challenges in complex mixtures. Optimizing your formulation requires choosing fumed silica for improved homogeneity and better interaction with binders and other additives.

Cost Analysis and Economic Considerations

Fumed silica typically incurs higher costs due to its complex manufacturing process involving high-temperature hydrolysis of silicon tetrachloride, resulting in superior purity and specific surface area. In contrast, precipitated silica is produced via a more economical wet chemical process, making it a cost-effective alternative for large-scale industrial applications. Your choice between these materials should balance performance needs against budget constraints, with precipitated silica offering economic advantages in bulk usage while fumed silica justifies its premium price through enhanced properties in specialized formulations.

Environmental Impact and Safety Concerns

Fumed silica production involves high-temperature vapor-phase processes that consume significant energy and release greenhouse gases, while precipitated silica manufacturing uses wet chemical methods with less energy but generates wastewater requiring treatment. Both materials pose inhalation risks as fine powders, with fumed silica typically having smaller particle sizes and higher surface areas, increasing respiratory exposure hazards. Proper handling, ventilation, and personal protective equipment are essential to mitigate occupational health risks and minimize environmental release during manufacturing and use.

Choosing Between Fumed and Precipitated Silica: Decision Factors

Choosing between fumed silica and precipitated silica depends on key decision factors such as particle size, surface area, and application requirements. Fumed silica features smaller primary particles and higher surface area, making it ideal for applications needing superior thickening and reinforcement properties, while precipitated silica offers larger particle sizes and is often preferred for cost-effective bulk use in rubber and plastics. Your choice should consider specific performance needs, dispersion characteristics, and processing conditions to optimize product functionality.

Fumed silica vs precipitated silica Infographic

libmatt.com

libmatt.com