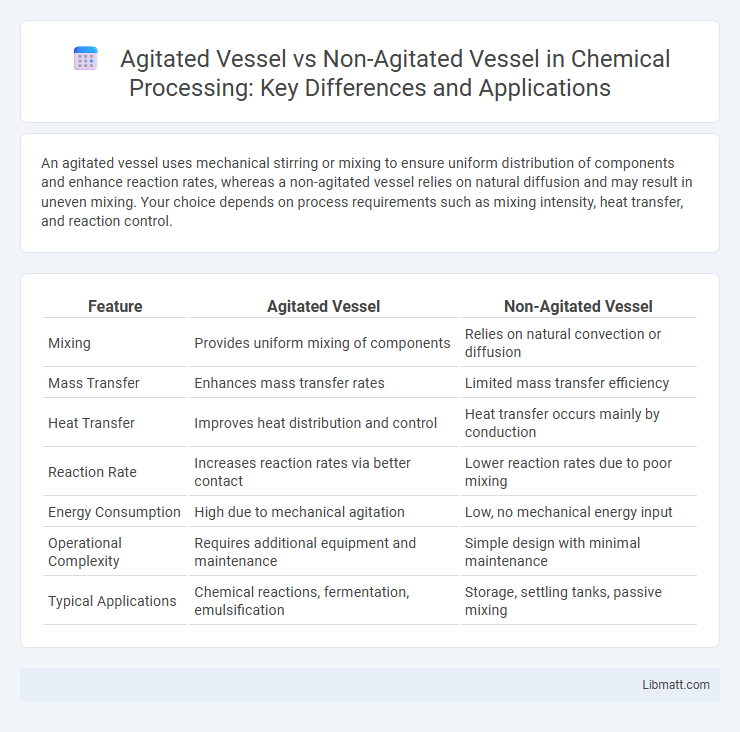

An agitated vessel uses mechanical stirring or mixing to ensure uniform distribution of components and enhance reaction rates, whereas a non-agitated vessel relies on natural diffusion and may result in uneven mixing. Your choice depends on process requirements such as mixing intensity, heat transfer, and reaction control.

Table of Comparison

| Feature | Agitated Vessel | Non-Agitated Vessel |

|---|---|---|

| Mixing | Provides uniform mixing of components | Relies on natural convection or diffusion |

| Mass Transfer | Enhances mass transfer rates | Limited mass transfer efficiency |

| Heat Transfer | Improves heat distribution and control | Heat transfer occurs mainly by conduction |

| Reaction Rate | Increases reaction rates via better contact | Lower reaction rates due to poor mixing |

| Energy Consumption | High due to mechanical agitation | Low, no mechanical energy input |

| Operational Complexity | Requires additional equipment and maintenance | Simple design with minimal maintenance |

| Typical Applications | Chemical reactions, fermentation, emulsification | Storage, settling tanks, passive mixing |

Introduction to Agitated and Non-Agitated Vessels

Agitated vessels use mechanical stirring or mixing to enhance mass transfer, heat distribution, and reaction rates, making them ideal for processes requiring uniformity and faster reactions. Non-agitated vessels rely on natural convection or diffusion, suitable for simpler storage or reactions where agitation could cause shear-sensitive damage. Understanding these differences helps you select the right vessel for your specific industrial or laboratory application.

Principle of Agitation in Vessel Operations

Agitation in vessel operations enhances mixing by creating turbulence that promotes uniform distribution of heat, chemicals, or solids, essential in processes like fermentation, chemical reactions, and slurry handling. Agitated vessels utilize impellers or mechanical stirrers to maintain homogeneity, prevent sedimentation, and improve mass transfer rates compared to non-agitated vessels where settling and stratification are common. Your choice of agitation intensity directly impacts reaction efficiency, scale-up potential, and operational control in industrial applications.

Key Components of Agitated Vessels

Agitated vessels feature key components such as an impeller or agitator, a motor, a shaft, and baffles to ensure effective mixing and prevent vortex formation. These vessels also include seals and bearings to support the rotating parts and maintain system integrity. Unlike non-agitated vessels, the design of agitated vessels is optimized for enhancing mass transfer, heat transfer, and uniformity in liquid-liquid or liquid-solid processes.

Design Features of Non-Agitated Vessels

Non-agitated vessels feature simpler design elements, including smooth interior surfaces and vertical or horizontal cylindrical shapes, optimized for passive storage without mechanical mixing. Unlike agitated vessels that require motor mounts and impeller assemblies, non-agitated vessels prioritize minimal internal obstructions to prevent contamination and facilitate easy cleaning. Your choice of a non-agitated vessel supports efficient storage and settling processes where agitation is unnecessary or potentially harmful.

Applications of Agitated Vessels in Industry

Agitated vessels are essential in industries such as pharmaceuticals, food processing, and chemical manufacturing due to their ability to enhance mixing, heat transfer, and reaction rates. They are used for blending liquids, suspending solids, and facilitating chemical reactions where uniformity and control over process parameters are critical. In contrast, non-agitated vessels are typically employed for storage or settling processes where minimal disturbance of contents is desired.

Common Uses of Non-Agitated Vessels

Non-agitated vessels are primarily used for storage and settling processes where mixing is unnecessary, such as holding tanks for liquids, decantation, and sedimentation. These vessels are ideal for applications requiring minimal shear stress and gentle handling to maintain fluid characteristics or allow solids to separate by gravity. Industries including wastewater treatment, chemical storage, and food processing frequently utilize non-agitated vessels to preserve product integrity and facilitate phase separation.

Advantages of Agitated Vessels

Agitated vessels enhance mass and heat transfer rates, promoting uniform temperature and concentration throughout the mixture, which is critical for reaction efficiency. They improve mixing of immiscible liquids and suspension of solid particles, preventing sedimentation and ensuring consistent product quality. Additionally, agitated vessels facilitate faster reaction kinetics and better control over chemical processes, making them ideal for complex industrial applications.

Limitations of Non-Agitated Vessels

Non-agitated vessels face significant limitations such as poor mixing efficiency, which leads to inconsistent temperature and concentration gradients within the vessel. This can cause uneven chemical reactions, reduced product quality, and longer processing times. You may encounter challenges in scaling up processes or handling viscous fluids due to inadequate agitation and poor mass transfer.

Factors Influencing Vessel Selection

Selection between agitated and non-agitated vessels depends on factors such as the physical properties of the material, desired mixing intensity, and process requirements like heat transfer or reaction kinetics. Agitated vessels excel when uniform mixing, mass transfer, or temperature control is critical, while non-agitated vessels are suitable for simple storage or settling processes. Your decision should consider viscosity, shear sensitivity, and scale to optimize efficiency and product quality.

Conclusion: Choosing the Right Vessel for Your Process

Selecting between an agitated vessel and a non-agitated vessel depends on the specific process requirements such as mixing, heat transfer, and reaction kinetics. Agitated vessels provide enhanced homogenization and faster mass transfer, ideal for processes needing uniform conditions and rapid chemical reactions. Non-agitated vessels suit applications with slow reactions or settling processes where minimal disturbance is beneficial, optimizing energy use and minimizing shear stress.

Agitated vessel vs non-agitated vessel Infographic

libmatt.com

libmatt.com