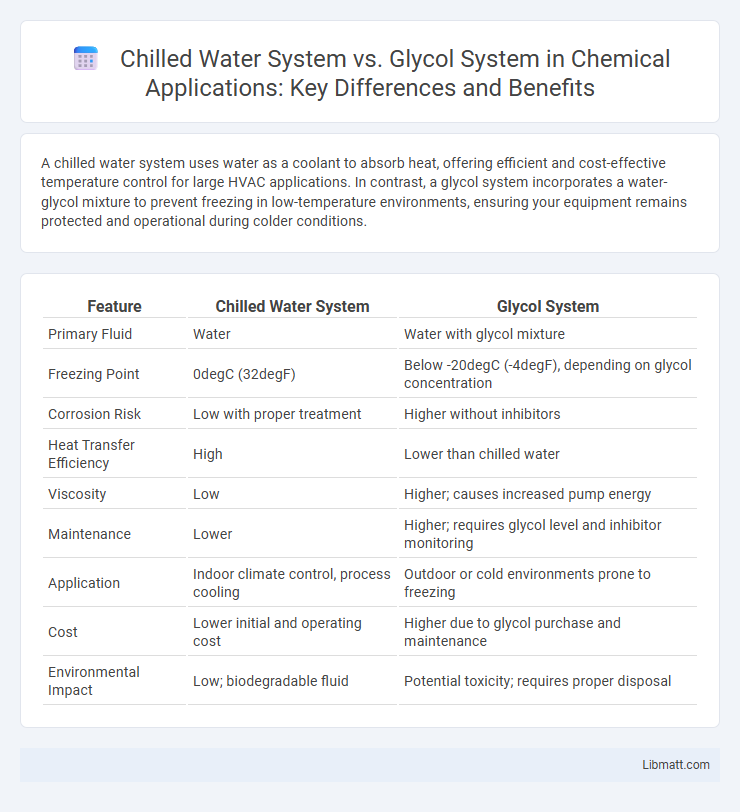

A chilled water system uses water as a coolant to absorb heat, offering efficient and cost-effective temperature control for large HVAC applications. In contrast, a glycol system incorporates a water-glycol mixture to prevent freezing in low-temperature environments, ensuring your equipment remains protected and operational during colder conditions.

Table of Comparison

| Feature | Chilled Water System | Glycol System |

|---|---|---|

| Primary Fluid | Water | Water with glycol mixture |

| Freezing Point | 0degC (32degF) | Below -20degC (-4degF), depending on glycol concentration |

| Corrosion Risk | Low with proper treatment | Higher without inhibitors |

| Heat Transfer Efficiency | High | Lower than chilled water |

| Viscosity | Low | Higher; causes increased pump energy |

| Maintenance | Lower | Higher; requires glycol level and inhibitor monitoring |

| Application | Indoor climate control, process cooling | Outdoor or cold environments prone to freezing |

| Cost | Lower initial and operating cost | Higher due to glycol purchase and maintenance |

| Environmental Impact | Low; biodegradable fluid | Potential toxicity; requires proper disposal |

Introduction to Chilled Water and Glycol Systems

Chilled water systems circulate cooled water to absorb heat from equipment or spaces, providing efficient temperature control in HVAC applications. Glycol systems use a mixture of water and glycol antifreeze to prevent freezing and corrosion in colder environments where chilled water alone might freeze. Your choice depends on climate, freeze protection needs, and system maintenance requirements for optimal performance.

Core Principles of Cooling: Chilled Water vs Glycol

Chilled water systems rely on water's high thermal capacity to absorb and transfer heat efficiently through a closed-loop piping network, making them ideal for large-scale HVAC applications. Glycol systems use a water-glycol mixture as the coolant, which lowers the freezing point and prevents freezing in low-temperature environments, ensuring reliable performance in colder climates. Your choice depends on temperature control needs and environmental conditions, with chilled water favoring moderate climates and glycol systems providing freeze protection where necessary.

Key Components Comparison

Chilled water systems primarily consist of chillers, cooling towers, pumps, and air handling units, utilizing water as the heat transfer medium for efficient building cooling. Glycol systems incorporate similar components but add glycol as an antifreeze agent, enabling operation in lower temperatures and reducing freezing risk in piping and equipment. The inclusion of glycol requires corrosion inhibitors and specialized pumps to handle the fluid's higher viscosity, impacting system design and maintenance requirements.

Temperature Range and Freezing Point Protection

Chilled water systems typically operate within a temperature range of 40degF to 45degF, maintaining efficient cooling without freezing risks, while glycol systems offer extended freezing point protection by lowering the fluid's freezing point to as low as -20degF or below, depending on the glycol concentration. Glycol mixtures safeguard Your equipment from freezing in cold environments, enabling system operation in subfreezing temperatures where chilled water alone might freeze and damage components. Selecting the right system depends on Your facility's temperature requirements and the need for robust freeze protection.

Energy Efficiency Considerations

Chilled water systems typically offer higher energy efficiency due to lower pumping power requirements and reduced fluid viscosity compared to glycol systems, which have higher thermal resistance and increased pumping energy demands. Glycol solutions are used primarily for freeze protection, but their lower heat transfer efficiency can lead to increased operational costs and energy consumption. Optimizing pipe insulation and selecting appropriate fluid mixtures can mitigate energy losses in glycol systems, yet chilled water systems generally remain superior for energy-efficient HVAC applications.

Maintenance Requirements and Longevity

Chilled water systems require regular maintenance of pumps, valves, and heat exchangers to prevent scaling and corrosion, typically extending their lifespan to 20-30 years with proper care. Glycol systems demand consistent monitoring and replenishment of glycol concentration to avoid freezing and microbial growth, which can reduce system longevity if neglected, though they generally last around 15-25 years. Both systems benefit from routine inspections and preventive maintenance to optimize performance and ensure extended operational life.

Environmental Impact and Safety

Chilled water systems typically use water, a non-toxic and environmentally friendly medium, while glycol systems rely on antifreeze solutions that can be toxic and require careful handling to prevent leaks and environmental contamination. Glycol solutions pose higher risks to both human safety and ecosystems due to their chemical nature, necessitating proper disposal and spill response measures. You can reduce environmental impact and enhance safety by choosing chilled water systems when feasible, as they minimize the potential hazards associated with glycol-based fluids.

Cost Analysis: Installation and Operation

Chilled water systems typically have lower initial installation costs due to simpler components and widely available infrastructure, but may incur higher operational expenses from energy consumption and maintenance of cooling towers. Glycol systems, by contrast, demand higher upfront investment for pumps, heat exchangers, and glycol purchase, yet benefit from reduced freeze risk, minimizing downtime and expensive emergency repairs in colder climates. Your choice between the two depends on balancing these installation and operational cost factors against site-specific temperature conditions and long-term efficiency goals.

Typical Applications in Industry and HVAC

Chilled water systems are widely used in large commercial buildings, industrial plants, and HVAC applications for efficient cooling through central air conditioning and process cooling. Glycol systems are preferred in environments requiring freeze protection, such as cold storage facilities, food processing plants, and outdoor HVAC units exposed to low temperatures. Both systems optimize thermal transfer but differ in fluid properties, with chilled water providing cost-effective cooling and glycol ensuring operational reliability in freezing conditions.

Choosing the Right System: Factors to Consider

Selecting between chilled water and glycol systems depends on factors such as ambient temperature, freeze protection needs, and system efficiency. Glycol systems offer superior freeze resistance, making them ideal for low-temperature environments, while chilled water systems provide better energy efficiency in moderate climates. Consider maintenance requirements, initial costs, and application-specific demands to determine the optimal choice for HVAC or industrial cooling projects.

chilled water system vs glycol system Infographic

libmatt.com

libmatt.com