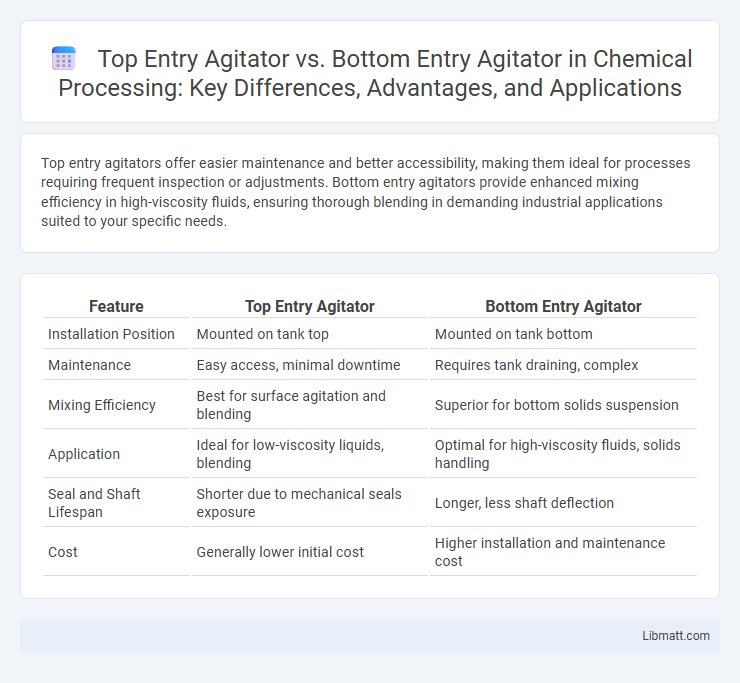

Top entry agitators offer easier maintenance and better accessibility, making them ideal for processes requiring frequent inspection or adjustments. Bottom entry agitators provide enhanced mixing efficiency in high-viscosity fluids, ensuring thorough blending in demanding industrial applications suited to your specific needs.

Table of Comparison

| Feature | Top Entry Agitator | Bottom Entry Agitator |

|---|---|---|

| Installation Position | Mounted on tank top | Mounted on tank bottom |

| Maintenance | Easy access, minimal downtime | Requires tank draining, complex |

| Mixing Efficiency | Best for surface agitation and blending | Superior for bottom solids suspension |

| Application | Ideal for low-viscosity liquids, blending | Optimal for high-viscosity fluids, solids handling |

| Seal and Shaft Lifespan | Shorter due to mechanical seals exposure | Longer, less shaft deflection |

| Cost | Generally lower initial cost | Higher installation and maintenance cost |

Introduction to Entry Agitators

Top entry agitators are mounted at the vessel's top, offering easy access for maintenance and ideal for mixing large volumes, ensuring efficient surface agitation and gas dispersion. Bottom entry agitators are installed at the base, enabling better suspension of settled solids and uniform mixing in shallow tanks, suitable for applications requiring reduced vortex formation. Your choice depends on tank design, mixing requirements, and the nature of the materials handled.

What is a Top Entry Agitator?

A Top Entry Agitator is a mechanical device mounted on the top of a tank, used to mix or blend liquids by rotating an impeller inside the vessel. Designed for efficient mixing in large tanks, it offers easy maintenance and good power transmission with minimal contamination risk. Commonly utilized in chemical processing, pharmaceuticals, and food industries, top entry agitators provide excellent agitation of low to medium viscosity fluids.

What is a Bottom Entry Agitator?

A bottom entry agitator is a mixing device mounted at the base of a tank or vessel, designed to provide efficient mixing in tall or large-scale containers by promoting bottom-up flow patterns. This type of agitator is ideal for handling high-viscosity fluids, maintaining uniformity in heavy slurries, and preventing sedimentation by ensuring thorough agitation near the vessel's floor. Your choice of a bottom entry agitator enhances mixing efficiency where traditional top entry agitators may struggle with deep or heavily loaded tanks.

Key Design Differences

Top entry agitators feature a shaft and impeller mounted from above the tank, allowing easy access for maintenance and flexible adjustment of impeller type to suit various mixing applications. Bottom entry agitators are installed at the tank base, offering superior mixing of high-viscosity fluids and minimizing vortex formation, while reducing the risk of contamination since the drive is located outside the tank. Your choice depends on factors like tank size, fluid properties, and maintenance accessibility, with top entry agitators better suited for general-purpose mixing and bottom entry agitators optimized for heavy-duty industrial processes.

Mixing Efficiency Comparison

Top entry agitators provide efficient surface blending and are ideal for applications involving low to medium viscosity fluids, ensuring faster homogenization by inducing axial flow. Bottom entry agitators excel in mixing high-viscosity materials and maintaining uniform suspension of solids by creating strong radial flow and minimizing dead zones. Selecting between top and bottom entry designs significantly impacts mixing efficiency depending on fluid properties and tank geometry.

Maintenance and Accessibility

Top entry agitators offer easier maintenance and accessibility due to their placement at the vessel's top, allowing quick inspection and service without emptying the tank. Bottom entry agitators, installed at the vessel's base, often require draining the tank and more complex disassembly, increasing downtime and maintenance labor. The accessibility advantage of top entry agitators reduces operational interruptions and maintenance costs in mixing processes.

Energy Consumption and Operational Costs

Top entry agitators generally consume more energy due to higher power requirements for mixing large volumes and overcoming surface resistance, leading to increased operational costs. Bottom entry agitators offer improved energy efficiency by directly targeting denser fluids and reducing hydraulic losses, which can lower energy consumption and maintenance expenses. Choosing the right agitator impacts Your operational budget by optimizing energy use and minimizing costly downtime.

Typical Applications for Each Type

Top entry agitators are commonly used in mixing processes involving large tanks where solid suspension, blending, or gas dispersion is required, such as in chemical reactors and fermentation tanks. Bottom entry agitators are preferred in applications demanding effective heat transfer and sludge suspension, like wastewater treatment and crystallizers, where avoiding seal maintenance at the tank top is crucial. Selecting between top or bottom entry agitators depends largely on the process requirements including tank size, agitation intensity, and maintenance constraints.

Pros and Cons of Top vs Bottom Entry Agitators

Top entry agitators provide easy access for maintenance and are ideal for mixing liquids with high viscosity or large vessel volumes, but they may generate more surface vortex and require more power. Bottom entry agitators offer better mixing efficiency with reduced vortex formation and lower power consumption, making them suitable for continuous processes or solids suspension, but they can be harder to service and maintain. Your choice depends on vessel design, mixing requirements, and maintenance accessibility preferences.

Choosing the Right Agitator for Your Process

Top entry agitators are ideal for processes requiring efficient mixing of liquids with low to moderate viscosity, offering easy installation and maintenance for open or semi-open tanks. Bottom entry agitators excel in handling high-viscosity fluids or heavy solids suspension, minimizing vessel intrusion and reducing contamination risk in sealed tanks. Selecting the right agitator depends on factors such as fluid properties, tank design, agitation intensity, and maintenance accessibility to optimize process efficiency and product quality.

Top entry agitator vs bottom entry agitator Infographic

libmatt.com

libmatt.com