Anion exchange resin and cation exchange resin differ primarily in the type of ions they remove from solutions: anion exchange resins attract and exchange negatively charged ions such as chloride, sulfate, and nitrate, while cation exchange resins target positively charged ions like calcium, magnesium, and sodium. Your choice between the two resins depends on the specific ions you need to remove for water purification or chemical processing applications.

Table of Comparison

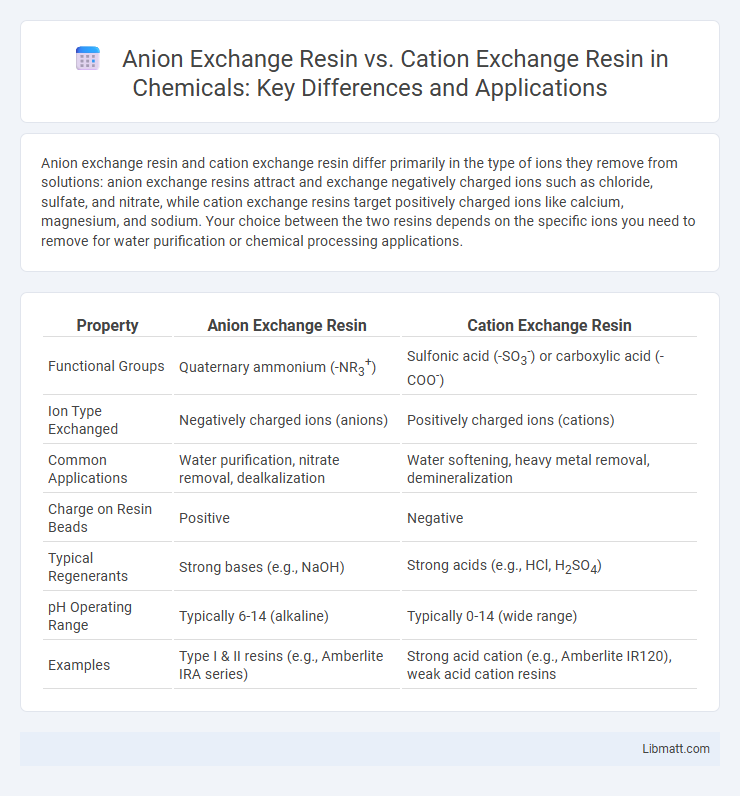

| Property | Anion Exchange Resin | Cation Exchange Resin |

|---|---|---|

| Functional Groups | Quaternary ammonium (-NR3+) | Sulfonic acid (-SO3-) or carboxylic acid (-COO-) |

| Ion Type Exchanged | Negatively charged ions (anions) | Positively charged ions (cations) |

| Common Applications | Water purification, nitrate removal, dealkalization | Water softening, heavy metal removal, demineralization |

| Charge on Resin Beads | Positive | Negative |

| Typical Regenerants | Strong bases (e.g., NaOH) | Strong acids (e.g., HCl, H2SO4) |

| pH Operating Range | Typically 6-14 (alkaline) | Typically 0-14 (wide range) |

| Examples | Type I & II resins (e.g., Amberlite IRA series) | Strong acid cation (e.g., Amberlite IR120), weak acid cation resins |

Introduction to Ion Exchange Resins

Ion exchange resins are synthetic polymers designed to exchange ions between the resin and surrounding solution, facilitating water purification and chemical separation. Anion exchange resins contain positively charged functional groups that attract and replace negatively charged ions such as chloride or sulfate. Cation exchange resins possess negatively charged functional groups, allowing them to target and exchange positively charged ions like calcium, magnesium, or sodium.

Overview: Anion vs Cation Exchange Resins

Anion exchange resins contain positively charged functional groups that attract and exchange negatively charged ions (anions) such as chloride, sulfate, and nitrate, whereas cation exchange resins have negatively charged functional groups designed to bind and exchange positively charged ions (cations) including calcium, magnesium, and sodium. Anion resins are commonly used for removing acidic contaminants and anions from water, while cation resins primarily target hardness ions and heavy metals. The efficiency of both resins depends on factors like ion selectivity, resin capacity, and operating conditions, making their selection crucial for water purification, wastewater treatment, and chemical processing applications.

Chemical Structure and Composition

Anion exchange resins consist of a polymer matrix functionalized with positively charged groups such as quaternary ammonium groups, designed to attract and exchange negatively charged ions like chloride or sulfate. Cation exchange resins contain negatively charged functional groups, often sulfonic acid or carboxylic acid groups, which bind positively charged ions such as sodium, calcium, or magnesium. The chemical structure of anion and cation exchange resins is based on a crosslinked polystyrene or polyacrylic matrix customized with different charged functional groups to enable selective ion exchange processes.

Mechanism of Ion Exchange

Anion exchange resin operates by attracting and exchanging negatively charged ions (anions) such as chloride, sulfate, and nitrate, while cation exchange resin targets positively charged ions (cations) like calcium, magnesium, and sodium. This ion exchange mechanism involves the resin's charged functional groups swapping their counter ions with ions in the surrounding solution, effectively removing unwanted ions from water or other fluids. Understanding this process helps you select the appropriate resin for applications like water softening, purification, or chemical separation based on the specific ions involved.

Key Applications and Uses

Anion exchange resins are primarily used in water purification processes to remove negatively charged contaminants such as nitrate, sulfate, and arsenic, making them essential in applications like wastewater treatment and drinking water softening. Cation exchange resins target positively charged ions like calcium, magnesium, and heavy metals, widely employed in water softening, metal recovery, and pharmaceutical manufacture. Your choice between anion and cation exchange resins depends on the specific ion removal requirement, ensuring optimal performance in industrial and environmental applications.

Performance and Selectivity

Anion exchange resins exhibit high performance in removing negatively charged ions such as nitrate and sulfate, while cation exchange resins are optimized for capturing positively charged ions like calcium and magnesium. The selectivity of anion resins depends on functional groups tailored to target specific anions, enhancing effectiveness in water softening and purification processes. Your choice between these resins should consider the type of ions present and desired selectivity to achieve optimal ion exchange capacity and regeneration efficiency.

Regeneration Processes

Anion exchange resin regeneration typically involves using a strong alkaline solution, such as sodium hydroxide, to replace captured anions and restore resin capacity. Cation exchange resin regeneration employs a strong acid, commonly hydrochloric or sulfuric acid, to displace bound cations and renew the resin's functionality. Understanding your system's specific ion exchange needs helps optimize regeneration frequency and chemical usage for efficient water treatment.

Advantages and Limitations

Anion exchange resins excel in removing negatively charged ions such as nitrates and sulfates, offering high selectivity and regeneration efficiency but may struggle with organic fouling and lower capacity for multivalent ions. Cation exchange resins effectively target positively charged ions like calcium and magnesium, providing excellent hardness removal and stability across a range of pH levels, yet they can be limited by slower regeneration cycles and sensitivity to high temperatures. Your choice depends on the specific ion removal needs and operational conditions, balancing resin type advantages against their limitations for optimal water treatment performance.

Factors Affecting Resin Selection

Resin selection depends on factors such as target ion type, water pH, and resin capacity; anion exchange resins effectively remove negatively charged ions like chloride and sulfate, while cation exchange resins target positively charged ions such as calcium and magnesium. Water hardness level, regeneration method, and operating temperature also influence whether an anion or cation exchange resin is ideal for a specific application. Resin selectivity and durability must align with the chemical composition and operational demands to optimize ion exchange efficiency.

Future Trends in Ion Exchange Technology

Future trends in ion exchange technology emphasize the development of high-capacity anion exchange resins with enhanced selectivity for nitrate and phosphate removal to address water pollution challenges. Advancements in cation exchange resins focus on improving thermal stability and regeneration efficiency for industrial wastewater treatment and metal recovery applications. Integration of bio-based and synthetic polymer matrices aims to increase resin biodegradability and sustainability, driving innovation in both anion and cation exchange materials.

Anion exchange resin vs cation exchange resin Infographic

libmatt.com

libmatt.com