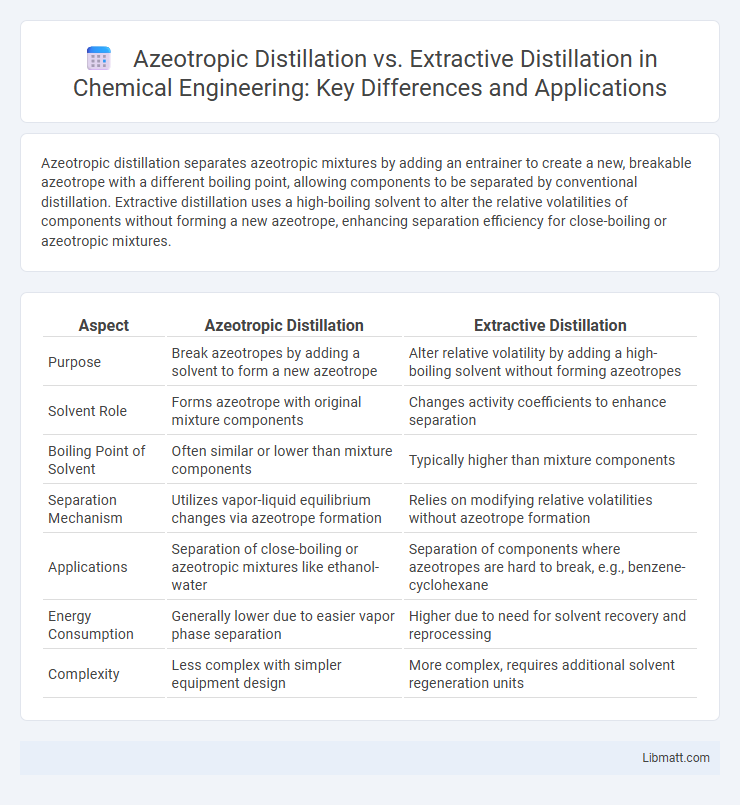

Azeotropic distillation separates azeotropic mixtures by adding an entrainer to create a new, breakable azeotrope with a different boiling point, allowing components to be separated by conventional distillation. Extractive distillation uses a high-boiling solvent to alter the relative volatilities of components without forming a new azeotrope, enhancing separation efficiency for close-boiling or azeotropic mixtures.

Table of Comparison

| Aspect | Azeotropic Distillation | Extractive Distillation |

|---|---|---|

| Purpose | Break azeotropes by adding a solvent to form a new azeotrope | Alter relative volatility by adding a high-boiling solvent without forming azeotropes |

| Solvent Role | Forms azeotrope with original mixture components | Changes activity coefficients to enhance separation |

| Boiling Point of Solvent | Often similar or lower than mixture components | Typically higher than mixture components |

| Separation Mechanism | Utilizes vapor-liquid equilibrium changes via azeotrope formation | Relies on modifying relative volatilities without azeotrope formation |

| Applications | Separation of close-boiling or azeotropic mixtures like ethanol-water | Separation of components where azeotropes are hard to break, e.g., benzene-cyclohexane |

| Energy Consumption | Generally lower due to easier vapor phase separation | Higher due to need for solvent recovery and reprocessing |

| Complexity | Less complex with simpler equipment design | More complex, requires additional solvent regeneration units |

Introduction to Distillation Processes

Azeotropic distillation separates components by adding an entrainer to break the azeotrope, altering relative volatilities and enabling separation of otherwise inseparable mixtures. Extractive distillation involves adding a high-boiling solvent to change the relative volatility of specific components without forming a new azeotrope, facilitating the separation of close-boiling or azeotropic mixtures. Both processes enhance conventional distillation by improving separation efficiency for complex liquid mixtures in industrial applications.

Understanding Azeotropic Distillation

Azeotropic distillation breaks the limitation of separating mixtures with close boiling points by adding a third component called an entrainer, which forms a new azeotrope with one of the original components, altering the volatility and enabling separation. This technique is essential when conventional distillation fails due to azeotropes that have constant boiling compositions. Understanding azeotropic distillation helps optimize your separation process, particularly in systems where binary mixtures form azeotropes and require special handling.

Fundamentals of Extractive Distillation

Extractive distillation involves adding a solvent to alter the relative volatilities of components in a mixture, enabling separation of close-boiling or azeotropic mixtures that cannot be separated by simple distillation. The solvent used in extractive distillation has a high affinity for one component, increasing the difference in volatility and facilitating efficient separation. This process relies on the solvent's selective interaction to modify vapor-liquid equilibria without forming new azeotropes, distinguishing it from azeotropic distillation where an entrainer creates a new azeotrope to break the original.

Key Differences Between Azeotropic and Extractive Distillation

Azeotropic distillation separates mixtures by adding an entrainer to form a new azeotrope, altering the relative volatility and enabling separation. Extractive distillation uses a solvent to change component interactions, increasing relative volatility without forming a new azeotrope. Key differences include the formation of an entrainer-induced azeotrope in azeotropic distillation versus a non-volatile solvent interaction in extractive distillation.

Types of Solvents Used in Both Methods

Azeotropic distillation typically employs entrainers such as benzene, cyclohexane, or toluene to break azeotropes by selectively altering relative volatilities, while extractive distillation uses high-boiling, non-volatile solvents like ethylene glycol, sulfolane, or glycerol to change the activity coefficients of components in the liquid phase. Solvents in azeotropic distillation form new, lower-boiling azeotropes with one of the mixture components, facilitating separation, whereas extractive distillation solvents enhance the difference in volatility without forming an azeotrope. The choice of solvent depends on the specific azeotrope or mixture and the desired separation efficiency and environmental or safety considerations.

Applications and Industry Use Cases

Azeotropic distillation excels in separating mixtures that form azeotropes, commonly used in the petrochemical and pharmaceutical industries to purify solvents like ethanol and benzene. Extractive distillation is preferred when separating close-boiling or non-ideal mixtures, widely applied in refining processes and chemical production such as separating xylene isomers and upgrading hydrocarbon streams. Your choice between these methods depends on the specific mixture properties and industry requirements for purity and efficiency.

Advantages and Limitations of Azeotropic Distillation

Azeotropic distillation offers the advantage of separating components with close boiling points by adding entrainers to break azeotropes, enhancing purity beyond conventional distillation limits. However, the process requires careful selection of entrainers, which can introduce additional costs and potential environmental concerns. Your choice of azeotropic distillation should consider the trade-off between improved separation efficiency and the complexity of handling entrainer recovery and recycling.

Benefits and Challenges of Extractive Distillation

Extractive distillation enhances separation of close-boiling or azeotropic mixtures by adding a solvent that alters relative volatilities, improving product purity without forming new azeotropes. The benefits include higher separation efficiency and the ability to separate mixtures that are difficult or impossible by conventional distillation. Challenges involve selecting an appropriate solvent with high selectivity, managing solvent recovery, and handling increased operational complexity and cost.

Energy Efficiency and Cost Comparison

Azeotropic distillation typically requires higher energy input due to the need for an entrainer to break the azeotrope, increasing operational costs. Extractive distillation is more energy-efficient by using a high-boiling solvent to alter relative volatilities, often resulting in lower steam consumption and reduced overall expenses. Cost comparisons favor extractive distillation in large-scale applications due to its improved energy utilization and reduced solvent recovery requirements.

Choosing the Right Distillation Method

Choosing the right distillation method depends on the specific azeotropic mixture and separation goals; azeotropic distillation is ideal for breaking azeotropes by adding an entrainer to alter relative volatilities, while extractive distillation uses a high-boiling solvent to change component volatilities without forming a new azeotrope. Key factors include the nature of the components, desired purity, process cost, and ease of solvent recovery. Selecting between these methods requires evaluating mixture composition, operational complexity, and energy efficiency to optimize separation performance.

azeotropic distillation vs extractive distillation Infographic

libmatt.com

libmatt.com