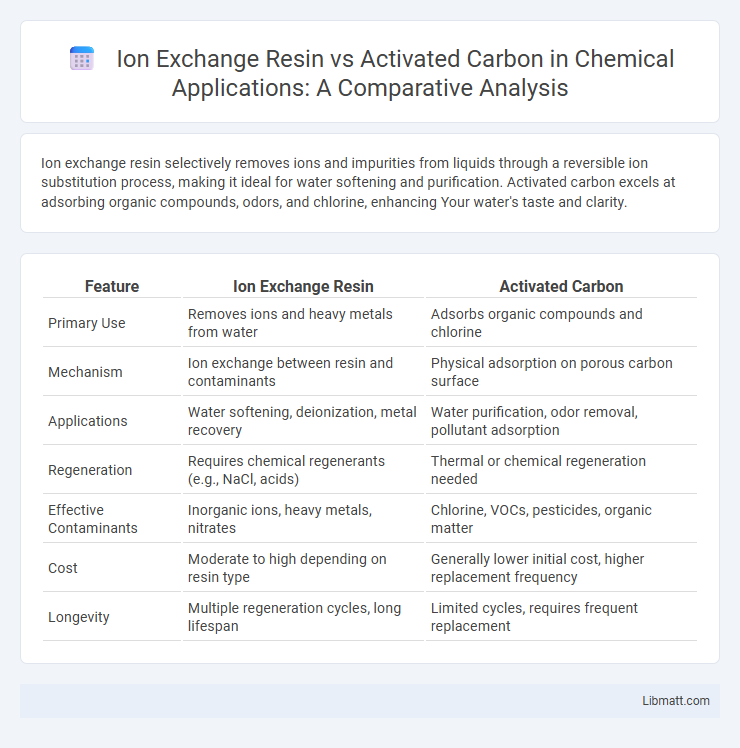

Ion exchange resin selectively removes ions and impurities from liquids through a reversible ion substitution process, making it ideal for water softening and purification. Activated carbon excels at adsorbing organic compounds, odors, and chlorine, enhancing Your water's taste and clarity.

Table of Comparison

| Feature | Ion Exchange Resin | Activated Carbon |

|---|---|---|

| Primary Use | Removes ions and heavy metals from water | Adsorbs organic compounds and chlorine |

| Mechanism | Ion exchange between resin and contaminants | Physical adsorption on porous carbon surface |

| Applications | Water softening, deionization, metal recovery | Water purification, odor removal, pollutant adsorption |

| Regeneration | Requires chemical regenerants (e.g., NaCl, acids) | Thermal or chemical regeneration needed |

| Effective Contaminants | Inorganic ions, heavy metals, nitrates | Chlorine, VOCs, pesticides, organic matter |

| Cost | Moderate to high depending on resin type | Generally lower initial cost, higher replacement frequency |

| Longevity | Multiple regeneration cycles, long lifespan | Limited cycles, requires frequent replacement |

Introduction to Ion Exchange Resin and Activated Carbon

Ion exchange resins are synthetic polymers designed to exchange specific ions within a solution, effectively removing contaminants like heavy metals and softening water. Activated carbon is a highly porous material derived from carbon-rich sources, widely used for adsorbing organic compounds, chlorine, and odors in water treatment. Both materials serve distinct purification roles, with ion exchange resins targeting ionic impurities and activated carbon excelling in the removal of non-ionic organic substances.

Fundamental Principles of Ion Exchange Resin

Ion exchange resin operates on the principle of exchanging ions between the resin's functional groups and the ions in the solution, effectively removing unwanted charged particles. This process relies on the resin's charged sites, typically cation or anion exchange groups, to selectively bind target ions such as calcium, magnesium, or heavy metals, making it ideal for water softening and purification. Your treatment system benefits from precise ion removal capabilities that activated carbon cannot provide, as activated carbon primarily functions through adsorption rather than ion replacement.

Core Mechanism of Activated Carbon

Activated carbon operates primarily through adsorption, where contaminants adhere to its porous surface due to van der Waals forces, effectively trapping organic compounds and chlorine. Its high surface area and microporous structure enable it to remove impurities without chemical reaction, making it ideal for improving water taste and odor. Your choice between activated carbon and ion exchange resin depends on whether you need physical adsorption or ion removal based on the specific contaminants in your water.

Comparative Adsorption Capabilities

Ion exchange resins exhibit superior selectivity for ionic contaminants such as heavy metals and nitrates due to their charged functional groups, enabling targeted removal from water sources. Activated carbon predominantly adsorbs organic compounds, chlorine, and certain gases through physical adsorption on its porous surface, making it highly effective for taste, odor, and organic pollutant removal. While ion exchange resins facilitate ion-specific exchange and regeneration, activated carbon focuses on broad-spectrum organic adsorption without ion replacement capabilities.

Applications in Water Treatment

Ion exchange resin and activated carbon serve distinct roles in water treatment: ion exchange resins effectively remove dissolved ions such as calcium, magnesium, and heavy metals, making them ideal for softening and demineralization processes. Activated carbon excels at adsorbing organic compounds, chlorine, and unpleasant odors, improving taste and reducing harmful contaminants. Your water treatment system can benefit from combining both materials for comprehensive purification and improved water quality.

Regeneration and Reusability

Ion exchange resins offer efficient regeneration through chemical treatments such as acid or base washes, allowing multiple reuse cycles with minimal loss in ion removal capacity. Activated carbon requires thermal or chemical regeneration processes that can be energy-intensive and may reduce adsorption efficiency over time. Ion exchange resins generally provide more consistent reusability in water treatment applications due to easier and less damaging regeneration methods.

Cost and Maintenance Considerations

Ion exchange resin generally incurs higher initial costs compared to activated carbon but offers longer service life and easier regeneration, reducing overall maintenance expenses. Activated carbon is typically less expensive upfront but requires more frequent replacement and can incur additional costs due to clogging and waste disposal. Your choice should balance initial investment with ongoing maintenance needs to optimize cost-efficiency.

Environmental Impact and Safety

Ion exchange resins and activated carbon differ significantly in environmental impact and safety; ion exchange resins, typically synthetic polymers, can pose disposal challenges due to their non-biodegradability and potential release of hazardous regeneration chemicals, whereas activated carbon, often derived from natural materials like coconut shells, is more environmentally friendly and biodegradable. Activated carbon effectively adsorbs a wide range of contaminants without introducing harmful substances, making it safer for water treatment with minimal ecological risks. However, ion exchange resins have higher regeneration chemical hazards, requiring careful handling and disposal protocols to mitigate environmental contamination and ensure user safety.

Selection Criteria for Specific Contaminants

Ion exchange resins are highly effective for removing specific charged contaminants like heavy metals, nitrates, and hardness ions due to their selective ion-exchange properties. Activated carbon excels in adsorbing organic compounds, chlorine, and volatile organic chemicals (VOCs), making it ideal for improving taste and odor in water. Your selection criteria should consider the contaminant type, concentration, and treatment goals to determine whether ion exchange resin or activated carbon offers the best removal efficiency.

Future Developments and Innovations

Future developments in ion exchange resin technology emphasize enhanced selectivity and regeneration efficiency through advanced polymer designs and nanocomposite materials. Activated carbon innovations focus on increasing surface area and functionalization with catalytic nanoparticles to improve adsorption capacity and target specific contaminants. Emerging hybrid systems integrating ion exchange resins with activated carbon aim to optimize water treatment processes by combining ion removal and organic contaminant adsorption.

ion exchange resin vs activated carbon Infographic

libmatt.com

libmatt.com