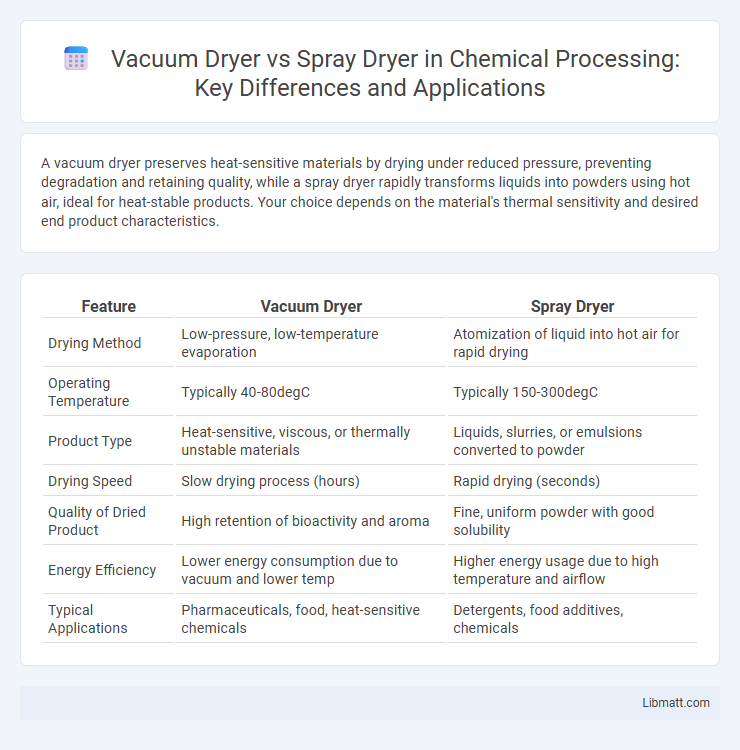

A vacuum dryer preserves heat-sensitive materials by drying under reduced pressure, preventing degradation and retaining quality, while a spray dryer rapidly transforms liquids into powders using hot air, ideal for heat-stable products. Your choice depends on the material's thermal sensitivity and desired end product characteristics.

Table of Comparison

| Feature | Vacuum Dryer | Spray Dryer |

|---|---|---|

| Drying Method | Low-pressure, low-temperature evaporation | Atomization of liquid into hot air for rapid drying |

| Operating Temperature | Typically 40-80degC | Typically 150-300degC |

| Product Type | Heat-sensitive, viscous, or thermally unstable materials | Liquids, slurries, or emulsions converted to powder |

| Drying Speed | Slow drying process (hours) | Rapid drying (seconds) |

| Quality of Dried Product | High retention of bioactivity and aroma | Fine, uniform powder with good solubility |

| Energy Efficiency | Lower energy consumption due to vacuum and lower temp | Higher energy usage due to high temperature and airflow |

| Typical Applications | Pharmaceuticals, food, heat-sensitive chemicals | Detergents, food additives, chemicals |

Introduction to Vacuum Dryer and Spray Dryer

Vacuum dryers operate by removing moisture under reduced pressure, allowing drying at lower temperatures which preserves heat-sensitive materials such as pharmaceuticals and food products. Spray dryers transform liquid feed into a fine mist, rapidly drying droplets using a hot air stream, ideal for producing powders with controlled particle size and moisture content. Both dryers are critical in industries requiring efficient drying but differ significantly in processing method and product application.

Key Differences Between Vacuum and Spray Dryers

Vacuum dryers operate by reducing pressure to lower the boiling point of liquids, making them ideal for heat-sensitive materials, whereas spray dryers atomize liquid feed into a hot drying chamber for rapid moisture removal. Vacuum drying typically yields better preservation of product quality and nutrients with slower drying times, while spray drying excels in producing fine, free-flowing powders suitable for large-scale production. The choice between vacuum and spray drying depends on factors like thermal sensitivity, desired particle size, drying speed, and production scale.

How Vacuum Dryers Work: Principles and Applications

Vacuum dryers operate by lowering the pressure around the material, enabling moisture to evaporate at reduced temperatures, which preserves heat-sensitive compounds. These dryers use a vacuum chamber to facilitate drying under sub-atmospheric pressure, enhancing energy efficiency and product quality in pharmaceuticals, food processing, and chemical industries. Applications include drying fragile materials like active pharmaceutical ingredients, herbs, and heat-sensitive polymers without causing thermal degradation.

Spray Dryer Technology: Process and Mechanism

Spray dryer technology converts liquid feed into dry powder through atomization, where your liquid is sprayed into a hot drying chamber, rapidly evaporating moisture. The process relies on efficient heat and mass transfer, with drying air temperature and feed rate critically controlling particle size and moisture content. This mechanism ensures uniform particle formation and high product quality, ideal for heat-sensitive materials compared to vacuum drying, which uses lower temperatures but slower drying rates.

Comparative Energy Efficiency: Vacuum vs. Spray Dryers

Vacuum dryers consume significantly less energy than spray dryers by operating at lower temperatures and pressures, which reduces heat loss and preserves product quality. Spray dryers require high temperatures and rapid air flow, leading to greater energy consumption and higher operational costs. Your choice between these drying methods can impact overall process efficiency and energy savings, with vacuum dryers often favored for energy-conscious applications.

Product Quality: Impact on Final Product Characteristics

Vacuum dryers preserve sensitive compounds by operating at lower temperatures, minimizing thermal degradation and maintaining the original texture, color, and flavor of heat-sensitive products. Spray dryers use rapid drying through hot air, which can sometimes alter the final product's morphology and cause nutrient loss, affecting quality. Your choice between vacuum and spray drying impacts the stability, moisture content, and overall integrity of the final product characteristics.

Suitable Materials for Vacuum and Spray Drying

Vacuum drying is ideal for heat-sensitive materials such as pharmaceuticals, food products, and delicate chemicals that degrade at high temperatures, preserving their quality by drying under reduced pressure and lower temperatures. Spray drying suits materials with heat stability and liquids needing rapid moisture removal, including dairy products, detergents, and chemicals, converting liquids into fine powders through atomization and hot gas contact. The choice between vacuum and spray drying depends on thermal sensitivity, material viscosity, and desired particle size.

Cost Analysis: Investment and Operating Expenses

Vacuum dryers typically require higher initial investment due to specialized equipment and maintenance needs, while spray dryers often involve greater operating expenses related to energy consumption and continuous labor. Your choice depends on balancing the lower energy costs and product quality advantages of vacuum dryers against the higher throughput but increased utility costs of spray dryers. A detailed cost analysis should factor in capital outlay, energy efficiency, and maintenance frequency specific to your production scale and material characteristics.

Common Industries Using Vacuum and Spray Dryers

Pharmaceutical, food processing, and chemical industries commonly use vacuum dryers for heat-sensitive materials requiring low-temperature drying to preserve quality and active compounds. Spray dryers are extensively utilized in dairy, beverage, and powdered food production for converting liquids into fine powders with rapid moisture removal and enhanced solubility. Both technologies are integral in cosmetics and biotechnology sectors for producing stable, high-purity dry products.

Choosing the Right Dryer: Key Considerations and Recommendations

Vacuum dryers excel in preserving heat-sensitive materials by operating at low temperatures and reducing oxidation risks, making them ideal for pharmaceuticals and food products requiring gentle drying. Spray dryers offer rapid drying through atomization, suitable for large-scale processing of liquids into fine powders, especially in dairy and chemical industries. Selecting the right dryer depends on product heat sensitivity, drying speed requirements, and scale of operation, with vacuum dryers favored for delicate substances and spray dryers for efficient mass production.

Vacuum dryer vs spray dryer Infographic

libmatt.com

libmatt.com