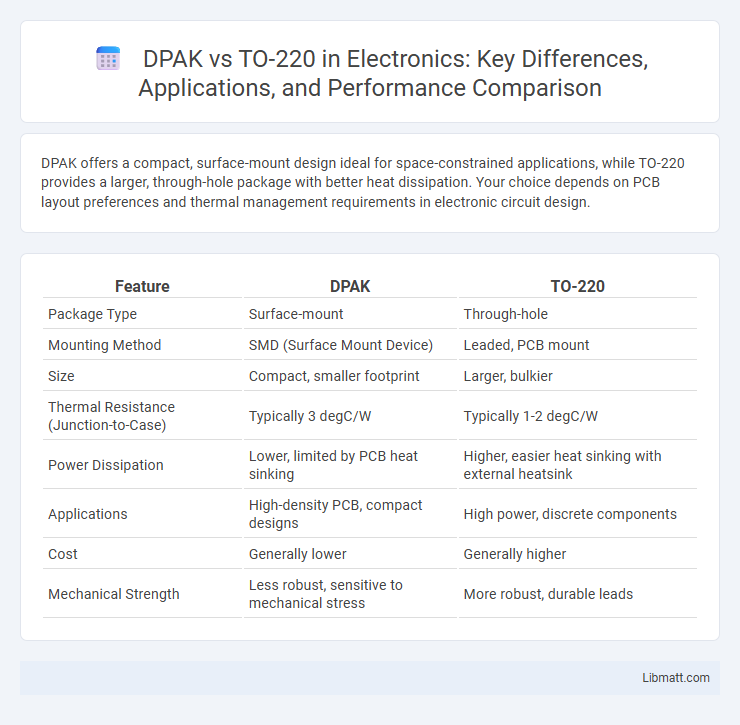

DPAK offers a compact, surface-mount design ideal for space-constrained applications, while TO-220 provides a larger, through-hole package with better heat dissipation. Your choice depends on PCB layout preferences and thermal management requirements in electronic circuit design.

Table of Comparison

| Feature | DPAK | TO-220 |

|---|---|---|

| Package Type | Surface-mount | Through-hole |

| Mounting Method | SMD (Surface Mount Device) | Leaded, PCB mount |

| Size | Compact, smaller footprint | Larger, bulkier |

| Thermal Resistance (Junction-to-Case) | Typically 3 degC/W | Typically 1-2 degC/W |

| Power Dissipation | Lower, limited by PCB heat sinking | Higher, easier heat sinking with external heatsink |

| Applications | High-density PCB, compact designs | High power, discrete components |

| Cost | Generally lower | Generally higher |

| Mechanical Strength | Less robust, sensitive to mechanical stress | More robust, durable leads |

Introduction to DPAK and TO-220 Packages

DPAK and TO-220 are popular semiconductor package types designed for power transistors and voltage regulators. DPAK, also known as TO-252, features a compact surface-mount design optimized for automated PCB assembly and efficient heat dissipation through its exposed metal pad. TO-220 packages offer through-hole mounting with a metal tab for enhanced thermal conductivity and easy attachment to heat sinks, making them suitable for high-power applications.

Overview of Semiconductor Packaging

DPAK and TO-220 are widely used semiconductor packages designed for efficient heat dissipation and reliable electrical performance in power devices. DPAK features a smaller surface-mount footprint ideal for automated PCB assembly, while TO-220 provides a through-hole design with a metal tab for enhanced thermal management in high-power applications. Both packages optimize semiconductor performance by balancing size, thermal resistance, and electrical connectivity in various electronic circuits.

DPAK: Features and Specifications

DPAK, also known as TO-252, is a compact surface-mount package widely used for power transistors and voltage regulators, offering excellent thermal performance due to its integrated heat sink tab. This package supports higher switching speeds and improved heat dissipation compared to traditional TO-220, making it ideal for space-constrained applications. Your design benefits from DPAK's low profile, high current handling capability up to several amps, and compatibility with automated PCB assembly processes.

TO-220: Features and Specifications

The TO-220 package features a larger size compared to DPAK, with a typical lead pitch of 2.54 mm and a three-lead configuration suitable for power transistors and voltage regulators. It offers enhanced thermal dissipation through a metal tab with a hole for heat sink mounting, supporting power ratings up to 50W depending on cooling conditions. Commonly used in high-power applications, TO-220 provides robust mechanical strength and ease of soldering or through-hole PCB mounting, making it ideal for power electronics requiring efficient heat management.

DPAK vs TO-220: Size Comparison

DPAK packages are significantly smaller in size compared to TO-220, making them ideal for compact and space-constrained circuit designs. The TO-220 typically measures around 10 mm by 15 mm with a protruding heatsink tab, while the DPAK package is more surface-mount friendly with dimensions roughly 6.5 mm by 6.7 mm. Choosing the right package size affects your PCB real estate and thermal management capabilities in power electronic applications.

Thermal Performance Analysis

DPAK packages exhibit improved thermal performance due to their larger exposed pad area, which enhances heat dissipation through PCB conduction compared to the TO-220's metal tab. The TO-220's design relies heavily on heatsinks for effective thermal management, as its tab presents a smaller direct thermal path to the ambient environment. In high-power applications, DPAK is preferred for surface-mount reliability and efficient heat transfer, while TO-220 remains suitable for through-hole mounting with external cooling solutions.

Electrical Characteristics Differences

DPAK and TO-220 packages differ significantly in electrical characteristics, primarily due to their thermal resistance and current handling capabilities. TO-220 typically offers lower junction-to-case thermal resistance, enabling higher power dissipation and better heat management compared to DPAK, which is optimized for surface-mount applications with compact size but higher thermal resistance. You should consider TO-220 for applications requiring higher current and efficient heat dissipation, whereas DPAK suits space-constrained designs with moderate power requirements.

Application Suitability: DPAK vs TO-220

DPAK packages are ideal for applications requiring compact, surface-mount designs with efficient heat dissipation in limited PCB space, commonly found in consumer electronics and automotive circuits. TO-220 packages excel in high-power applications with through-hole mounting, offering superior thermal performance and ease of heat sink attachment for industrial and power supply devices. Selecting between DPAK and TO-220 depends on the thermal requirements, assembly process, and space constraints of the specific electronic application.

Cost and Availability Considerations

DPAK packages generally offer lower costs and higher availability for surface-mount assembly in mass production compared to TO-220, which is often more expensive due to its through-hole design and larger size. TO-220 components, favored for their robust heat dissipation and ease of manual replacement, tend to have limited availability in high-volume automated assembly lines. The choice between DPAK and TO-220 significantly impacts budgeting and procurement efficiency in electronic manufacturing.

Choosing Between DPAK and TO-220 for Your Design

Choosing between DPAK and TO-220 packages depends primarily on your design's power dissipation and space constraints. DPAK offers a compact surface-mount solution with efficient heat dissipation suitable for high-density circuit boards, while TO-220 provides superior thermal performance with a robust through-hole design ideal for higher current applications. Evaluate your thermal management needs and PCB real estate carefully to ensure optimal component selection for your project's reliability and performance.

DPAK vs TO-220 Infographic

libmatt.com

libmatt.com