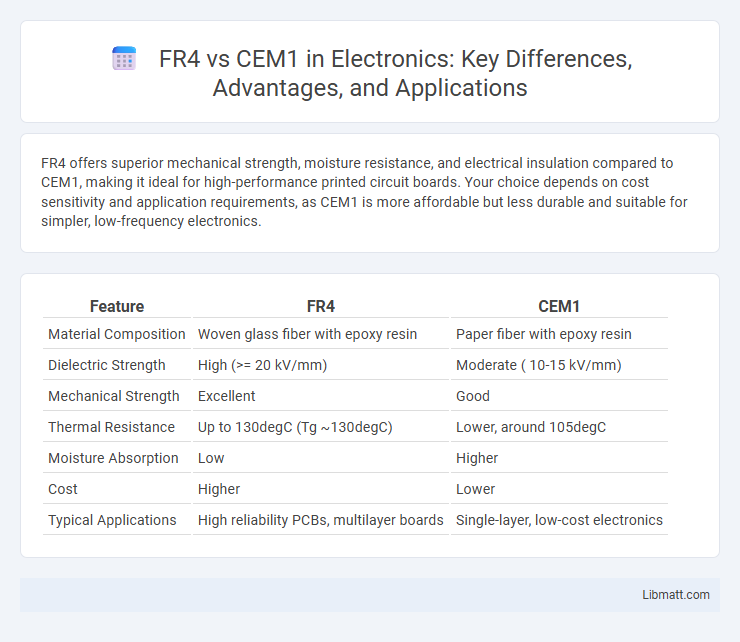

FR4 offers superior mechanical strength, moisture resistance, and electrical insulation compared to CEM1, making it ideal for high-performance printed circuit boards. Your choice depends on cost sensitivity and application requirements, as CEM1 is more affordable but less durable and suitable for simpler, low-frequency electronics.

Table of Comparison

| Feature | FR4 | CEM1 |

|---|---|---|

| Material Composition | Woven glass fiber with epoxy resin | Paper fiber with epoxy resin |

| Dielectric Strength | High (>= 20 kV/mm) | Moderate ( 10-15 kV/mm) |

| Mechanical Strength | Excellent | Good |

| Thermal Resistance | Up to 130degC (Tg ~130degC) | Lower, around 105degC |

| Moisture Absorption | Low | Higher |

| Cost | Higher | Lower |

| Typical Applications | High reliability PCBs, multilayer boards | Single-layer, low-cost electronics |

Introduction to FR4 and CEM1

FR4 is a widely used high-quality fiberglass-reinforced epoxy laminate known for its excellent mechanical strength, electrical insulation properties, and flame resistance, making it ideal for complex and high-performance printed circuit boards (PCBs). CEM1 is a cost-effective, cellulose paper-based composite material with a single layer of woven glass fabric, offering sufficient mechanical and electrical properties for simpler, low-volume PCB applications. The choice between FR4 and CEM1 depends on factors such as durability requirements, thermal stability, and budget constraints in electronic circuit design.

Material Composition and Structure

FR4 is composed of woven fiberglass cloth impregnated with epoxy resin, providing superior mechanical strength, electrical insulation, and moisture resistance. In contrast, CEM1 consists of a cellulose paper core combined with a single layer of woven glass fabric and epoxy resin, resulting in a more economical but less durable PCB substrate. The structural differences influence thermal stability and dimensional consistency, with FR4 offering higher performance in demanding electronic applications compared to CEM1.

Mechanical Properties Comparison

FR4 offers superior mechanical strength and rigidity compared to CEM1, making it ideal for applications requiring high durability and resistance to stress. CEM1, composed of paper-based materials, exhibits lower tensile strength and is more prone to warping under heat or mechanical loads. Your choice between FR4 and CEM1 should consider the mechanical demands of the final product to ensure optimal performance and longevity.

Electrical Performance Differences

FR4 exhibits superior electrical performance compared to CEM1, primarily due to its lower dielectric constant (around 4.5) and dielectric loss, which result in better signal integrity and reduced signal attenuation. CEM1 typically has a higher dielectric constant (approximately 5.0 to 5.5) and greater moisture absorption, leading to increased electrical losses and lower insulation resistance. These differences make FR4 more suitable for high-frequency and high-performance electronic applications.

Thermal Resistance and Heat Management

FR4 exhibits superior thermal resistance compared to CEM1, making it more effective for high-temperature applications and efficient heat management in electronic circuits. Its epoxy resin base combined with woven fiberglass provides better insulation and stability under heat stress, reducing the risk of board warping or failure. When optimizing your design for thermal reliability, selecting FR4 ensures enhanced durability and performance in demanding thermal environments.

Cost Analysis: FR4 vs CEM1

FR4 offers superior mechanical strength and thermal resistance compared to CEM1, but it comes with a higher material and processing cost. CEM1 is a cost-effective alternative suitable for less demanding applications, often preferred in single-sided or low-layer PCBs due to its lower price point. The choice between FR4 and CEM1 significantly impacts overall production expenses, with FR4 increasing durability investments while CEM1 reduces upfront manufacturing costs.

Applications and Use Cases

FR4 is widely used in high-frequency and multilayer printed circuit boards (PCBs) due to its superior electrical insulation and mechanical stability, making it ideal for computers, telecommunications, and consumer electronics. CEM1, with its cost-effective phenolic resin and paper base, is preferred for single-layer, low-cost applications such as LED lighting, basic electronic toys, and simple household appliances. Your choice between FR4 and CEM1 should consider the complexity and durability requirements of your electronic design.

Durability and Reliability Factors

FR4 offers superior durability and reliability compared to CEM1 due to its epoxy resin composition reinforced with woven fiberglass, which provides enhanced mechanical strength and moisture resistance. CEM1, made from paper-based phenolic resin, is more susceptible to delamination and dimensional instability under thermal stress and high humidity, making it less reliable for long-term applications. Choosing FR4 for your PCB ensures greater resilience against environmental factors, resulting in more consistent performance and longer lifespan.

Environmental Impact and Sustainability

FR4 offers better durability and longer lifespan compared to CEM1, resulting in reduced electronic waste and a lower environmental footprint over time. CEM1, although cost-effective, is less resistant to moisture and heat, often leading to quicker degradation and increased material disposal. Your choice of FR4 supports sustainability efforts by promoting product longevity and minimizing hazardous waste in electronics manufacturing.

Choosing the Right PCB Material

Choosing the right PCB material depends on your project's electrical, mechanical, and thermal requirements, where FR4 offers superior flame resistance, dimensional stability, and dielectric strength compared to CEM1. FR4 is a glass-reinforced epoxy laminate ideal for high-performance, multilayer boards, while CEM1 is a composite paper-based laminate suitable for low-cost, single-layer applications. Your choice impacts the durability, signal integrity, and manufacturing complexity of your PCB.

FR4 vs CEM1 Infographic

libmatt.com

libmatt.com