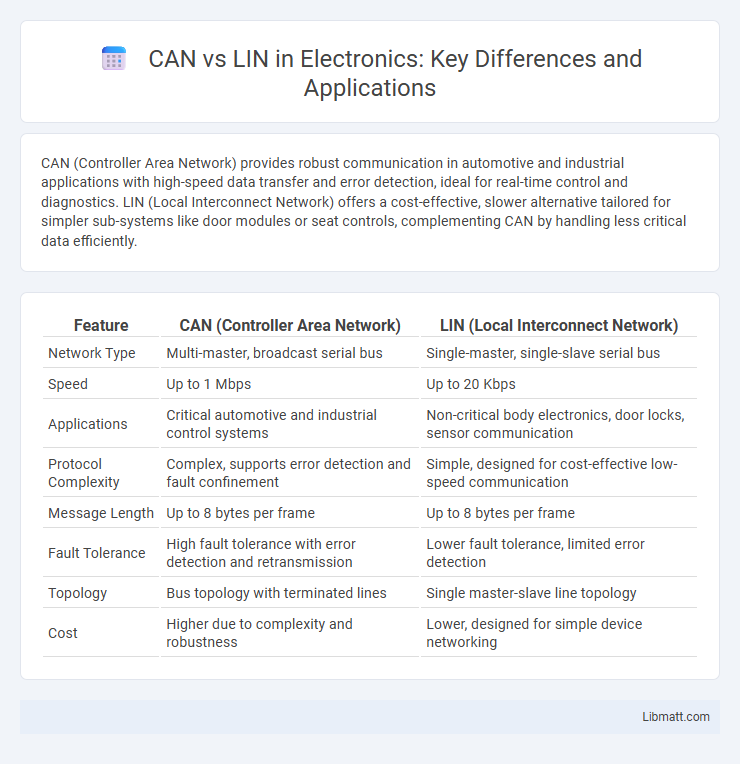

CAN (Controller Area Network) provides robust communication in automotive and industrial applications with high-speed data transfer and error detection, ideal for real-time control and diagnostics. LIN (Local Interconnect Network) offers a cost-effective, slower alternative tailored for simpler sub-systems like door modules or seat controls, complementing CAN by handling less critical data efficiently.

Table of Comparison

| Feature | CAN (Controller Area Network) | LIN (Local Interconnect Network) |

|---|---|---|

| Network Type | Multi-master, broadcast serial bus | Single-master, single-slave serial bus |

| Speed | Up to 1 Mbps | Up to 20 Kbps |

| Applications | Critical automotive and industrial control systems | Non-critical body electronics, door locks, sensor communication |

| Protocol Complexity | Complex, supports error detection and fault confinement | Simple, designed for cost-effective low-speed communication |

| Message Length | Up to 8 bytes per frame | Up to 8 bytes per frame |

| Fault Tolerance | High fault tolerance with error detection and retransmission | Lower fault tolerance, limited error detection |

| Topology | Bus topology with terminated lines | Single master-slave line topology |

| Cost | Higher due to complexity and robustness | Lower, designed for simple device networking |

Introduction to CAN and LIN Protocols

Controller Area Network (CAN) protocol is a robust vehicle bus standard designed for real-time communication between microcontrollers and devices in automotive and industrial systems, supporting high-speed data transfer up to 1 Mbps. Local Interconnect Network (LIN) protocol provides a lower-cost, slower alternative for simpler, lower-speed communication in automotive applications, typically operating at 20 Kbps and used for sub-systems like door modules and climate control. CAN features multi-master arbitration and error-handling capabilities, whereas LIN operates as a single-master, multiple-slave protocol with simpler implementation and lower bandwidth requirements.

Overview of Automotive Communication Networks

Controller Area Network (CAN) is a robust vehicle bus standard designed for real-time, high-speed communication between electronic control units (ECUs) in modern automotive systems, ensuring reliable data transmission and fault tolerance. Local Interconnect Network (LIN) serves as a cost-effective, lower-speed protocol for simpler subsystems such as door modules and climate control, complementing CAN by handling non-critical communication tasks. Both networks are integral to in-vehicle communication architectures, where CAN manages complex, safety-critical functions and LIN supports ancillary, sensor-level connectivity.

CAN Protocol: Features and Applications

CAN protocol offers robust communication with high data transfer rates up to 1 Mbps and excellent error detection capabilities, making it ideal for automotive and industrial control systems. Its multi-master architecture supports real-time data exchange between multiple devices, enhancing system reliability and fault tolerance. You can utilize CAN in applications requiring precise synchronization and rapid message delivery, such as vehicle diagnostics, engine control units, and factory automation.

LIN Protocol: Features and Use Cases

LIN protocol, developed for automotive networking, offers a low-cost, single-wire communication system ideal for body electronics such as door modules, climate control, and seat positioning. It supports a master-slave architecture with up to 16 nodes, providing deterministic data transfer and simplified integration in vehicle subsystems. LIN is widely used alongside CAN, complementing it by handling non-critical control functions where low bandwidth and cost efficiency are prioritized.

Comparative Architecture: CAN vs LIN

CAN (Controller Area Network) features a multi-master, message-oriented protocol with robust error handling and high-speed data transfer up to 1 Mbps, ideal for complex, real-time automotive systems. LIN (Local Interconnect Network) employs a simpler, single-master, slave architecture with slower data rates up to 20 Kbps, designed for cost-effective communication in non-critical subsystems. Your choice between CAN and LIN depends on system complexity, required data speed, and network reliability needs.

Data Transmission Speed and Efficiency

CAN (Controller Area Network) supports data transmission speeds up to 1 Mbps, making it highly efficient for real-time automotive and industrial applications requiring fast and reliable communication. LIN (Local Interconnect Network) operates at lower speeds, typically up to 20 Kbps, optimized for simpler, cost-sensitive tasks such as sensor and actuator communication in vehicle subsystems. The higher bandwidth and collision-handling capabilities of CAN enable more complex and time-critical messaging compared to LIN's slower, master-slave protocol designed for efficient low-speed data exchange.

Network Topology and Scalability

CAN uses a multi-master, broadcast topology supporting up to 1 Mbps and allows up to 112 nodes, making it ideal for complex systems requiring high reliability and scalability. LIN operates on a single-master, multiple-slave bus topology with a maximum data rate of 20 Kbps, suited for simpler, low-cost networks with up to 16 nodes. Your choice between CAN and LIN depends on the required network size, speed, and complexity of your automotive or industrial communication system.

Cost Analysis: Implementation and Maintenance

CAN (Controller Area Network) systems generally involve higher initial costs due to complex hardware and robust error-checking mechanisms, but their reliability reduces long-term maintenance expenses. LIN (Local Interconnect Network) offers a more cost-effective solution with simpler implementation and lower hardware requirements, making it ideal for less critical applications demanding minimal budget. Your choice between CAN and LIN should consider the balance of upfront investment versus ongoing maintenance costs tailored to your project's complexity and reliability needs.

Use Cases: When to Choose CAN or LIN

CAN (Controller Area Network) is ideal for complex, high-speed communication tasks such as engine control units, advanced driver-assistance systems (ADAS), and real-time data exchange in automotive and industrial environments. LIN (Local Interconnect Network) serves as a cost-effective solution for simpler, low-speed applications like window controls, seat adjustments, and interior lighting systems where fewer nodes and lower data rates are sufficient. You should choose CAN when reliability and speed are critical, whereas LIN is suitable for non-critical, economical communication tasks within vehicle subsystems.

Future Trends in Automotive Networking

Future trends in automotive networking emphasize the integration of CAN (Controller Area Network) and LIN (Local Interconnect Network) protocols to enhance vehicle communication efficiency and flexibility. CAN remains the backbone for high-speed, critical data transfer in advanced driver-assistance systems (ADAS) and electric vehicle (EV) architectures, while LIN supports cost-effective, low-speed sensor and actuator networks. Emerging technologies aim to combine CAN's robustness with LIN's simplicity, facilitating scalable, interoperable networks for autonomous driving and connected car platforms.

CAN vs LIN Infographic

libmatt.com

libmatt.com