Thru-hole reflow soldering provides precise, consistent heat application ideal for complex or mixed-technology boards, enhancing solder joint reliability. Your choice between thru-hole reflow and wave soldering should consider factors like production volume, component type, and thermal sensitivity for optimal assembly quality.

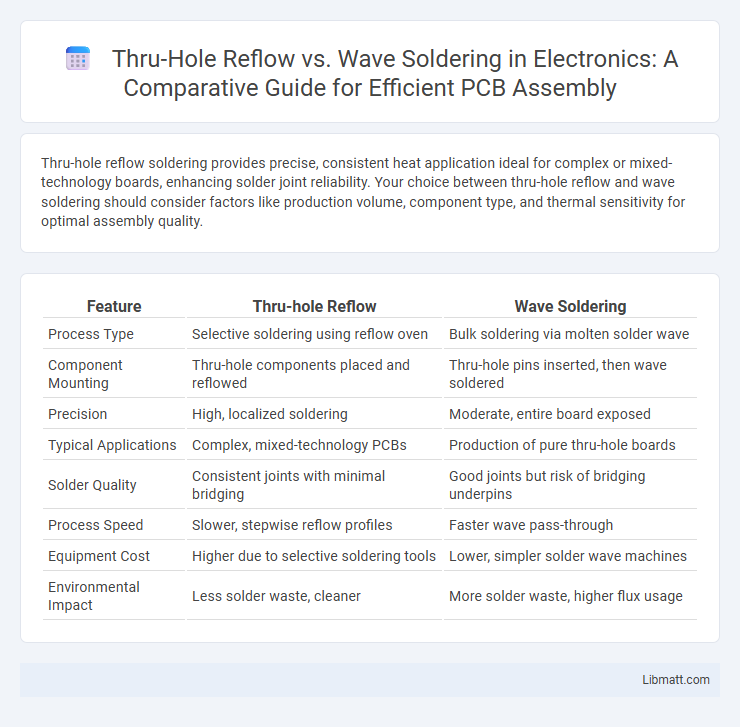

Table of Comparison

| Feature | Thru-hole Reflow | Wave Soldering |

|---|---|---|

| Process Type | Selective soldering using reflow oven | Bulk soldering via molten solder wave |

| Component Mounting | Thru-hole components placed and reflowed | Thru-hole pins inserted, then wave soldered |

| Precision | High, localized soldering | Moderate, entire board exposed |

| Typical Applications | Complex, mixed-technology PCBs | Production of pure thru-hole boards |

| Solder Quality | Consistent joints with minimal bridging | Good joints but risk of bridging underpins |

| Process Speed | Slower, stepwise reflow profiles | Faster wave pass-through |

| Equipment Cost | Higher due to selective soldering tools | Lower, simpler solder wave machines |

| Environmental Impact | Less solder waste, cleaner | More solder waste, higher flux usage |

Introduction to Thru-hole Reflow and Wave Soldering

Thru-hole reflow soldering involves placing components with leads through pre-drilled holes on the PCB and then passing the assembly through a reflow oven to melt solder paste, ensuring strong mechanical and electrical connections. Wave soldering uses a wave of molten solder to simultaneously solder all components on the underside of the PCB, ideal for high-volume production of boards with thru-hole and mixed technology components. Both methods serve essential roles in PCB assembly, with thru-hole reflow offering precise heat control and wave soldering providing efficient bulk soldering for robust joint formation.

Understanding Thru-hole Reflow Soldering

Thru-hole reflow soldering involves placing components with leads through pre-drilled holes in the PCB, followed by applying solder paste and heating to melt the solder, ensuring strong mechanical and electrical connections. This method offers precise control over solder joints and is suitable for complex, high-reliability assemblies where wave soldering might cause bridging or insufficient soldering. Your production process benefits from improved joint consistency and reduced defects when opting for thru-hole reflow soldering over traditional wave soldering.

Overview of Wave Soldering Technology

Wave soldering technology employs a continuous wave of molten solder to simultaneously join through-hole components to printed circuit boards, ensuring strong mechanical and electrical connections. This process is highly efficient for mass production, offering consistent solder joints with excellent reliability and reduced labor compared to manual soldering. Your manufacturing workflow benefits from faster assembly times and improved solder quality using wave soldering for through-hole applications.

Key Differences Between Thru-hole Reflow and Wave Soldering

Thru-hole reflow soldering involves placing solder paste on component leads and heating them to create joints, offering precise control and suitability for complex, high-density PCBs. Wave soldering uses a wave of molten solder to simultaneously solder all through-hole components, providing high throughput but less control over individual joints. Your choice depends on assembly volume, component complexity, and desired solder quality.

Process Steps: Thru-hole Reflow vs Wave Soldering

Thru-hole reflow soldering involves applying solder paste to PCB pads, inserting components into drilled holes, and heating the assembly in a reflow oven to melt the solder and form reliable joints. Wave soldering passes the assembled PCB over a wave of molten solder, allowing the solder to make contact with all exposed metallic surfaces simultaneously, primarily used for mass processing of through-hole components. The key difference lies in the controlled heat profile of reflow ovens targeting specific joints, while wave soldering exposes the entire bottom side of the board to soldering waves.

Material and Equipment Requirements

Thru-hole reflow soldering requires solder paste, stencils, and a reflow oven capable of precise temperature profiling, ensuring controlled melting of solder on component leads through PCB holes. Wave soldering demands flux application systems, a solder pot with a flowing wave, and conveyor mechanisms to immerse the PCB bottom side, necessitating materials resistant to prolonged exposure to molten solder. Both techniques require carefully selected PCB substrates and component leads compatible with high thermal stress to maintain joint reliability during the soldering process.

Advantages of Thru-hole Reflow Soldering

Thru-hole reflow soldering offers superior precision and control compared to wave soldering, resulting in higher-quality joints and reduced risk of component damage. This method supports complex PCB designs with densely packed components and allows for automated, consistent soldering processes that improve production efficiency. Enhanced thermal profiling in thru-hole reflow ensures reliable solder joints, boosting overall device performance and durability.

Benefits of Wave Soldering

Wave soldering offers significant benefits including high throughput production and excellent solder joint reliability for through-hole components. It ensures uniform solder application, reducing the risk of cold joints and improving electrical connectivity. Large-scale manufacturing benefits from wave soldering's efficiency and repeatability, enabling cost-effective assembly processes.

Application Suitability and Industry Use Cases

Thru-hole reflow is highly suitable for complex, high-density circuit boards found in aerospace and medical devices, where precision and component reliability are critical. Wave soldering excels in mass production of simpler PCBs, commonly used in automotive and consumer electronics due to its efficiency and cost-effectiveness. Your choice depends on the specific application needs, balancing complexity, volume, and industry standards for optimal soldering performance.

Choosing the Right Soldering Method for Your PCB Assembly

Thru-hole reflow soldering provides precise control and is ideal for complex, densely populated PCBs with mixed component types, ensuring strong mechanical bonds and reliable electrical connections. Wave soldering suits high-volume production of predominantly thru-hole components, offering fast throughput and cost efficiency, especially for simpler board layouts. Selecting the right soldering method depends on factors like PCB design complexity, component types, production volume, and quality requirements to optimize performance and manufacturing costs.

Thru-hole Reflow vs Wave Soldering Infographic

libmatt.com

libmatt.com