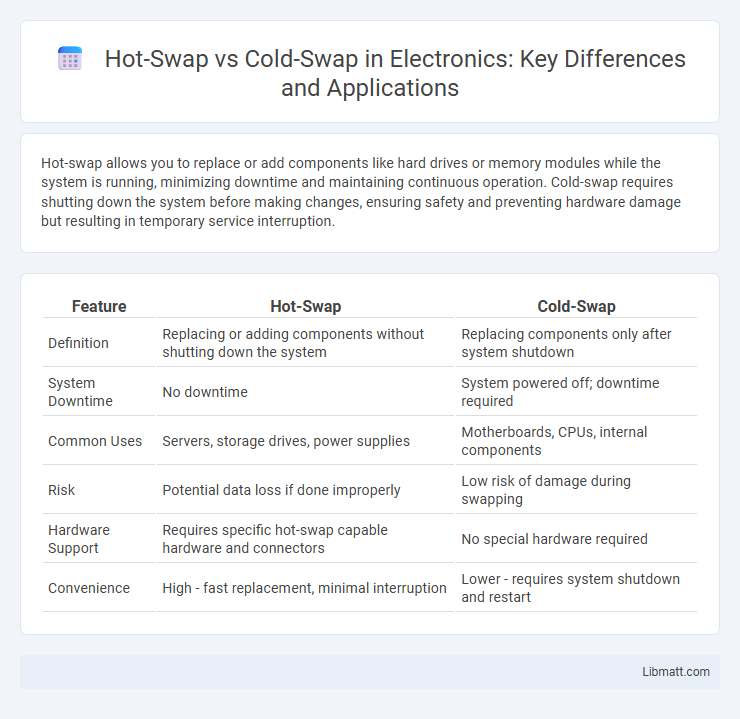

Hot-swap allows you to replace or add components like hard drives or memory modules while the system is running, minimizing downtime and maintaining continuous operation. Cold-swap requires shutting down the system before making changes, ensuring safety and preventing hardware damage but resulting in temporary service interruption.

Table of Comparison

| Feature | Hot-Swap | Cold-Swap |

|---|---|---|

| Definition | Replacing or adding components without shutting down the system | Replacing components only after system shutdown |

| System Downtime | No downtime | System powered off; downtime required |

| Common Uses | Servers, storage drives, power supplies | Motherboards, CPUs, internal components |

| Risk | Potential data loss if done improperly | Low risk of damage during swapping |

| Hardware Support | Requires specific hot-swap capable hardware and connectors | No special hardware required |

| Convenience | High - fast replacement, minimal interruption | Lower - requires system shutdown and restart |

Introduction to Hot-Swap and Cold-Swap

Hot-swap refers to the ability to replace or add components to a system without shutting it down, ensuring continuous operation, commonly used in servers and storage devices. Cold-swap requires powering down the system before changing hardware to prevent damage and data loss, typically seen in desktops and older equipment. Your choice between hot-swap and cold-swap depends on system design and operational priority for uptime versus safety.

Defining Hot-Swap: Key Features

Hot-swap refers to the capability of adding or removing hardware components, such as hard drives or power supplies, from a computer system without shutting it down, ensuring continuous operation. Key features of hot-swap include immediate recognition by the system, support for interrupts to manage device connections, and minimal interruption in system performance. This functionality is critical in data centers and enterprise environments where uptime and system availability are paramount.

Understanding Cold-Swap: Core Concepts

Cold-swap refers to the process of removing or installing hardware components while the system is completely powered off, ensuring no electrical current flows through the device during the swap. This method minimizes the risk of data corruption or hardware damage, as power-dependent components are inactive, making it suitable for systems without hot-swap capabilities. Understanding cold-swap is essential for maintaining hardware integrity in environments where uninterrupted power supply is unavailable or hot-swapping is unsupported.

Technical Differences Between Hot-Swap and Cold-Swap

Hot-swap technology allows components to be replaced or added without shutting down the system, utilizing hardware interfaces designed for live replacement such as SATA or USB connectors. Cold-swap requires powering down the device before removing or installing components to prevent data corruption or hardware damage, common in motherboards or internal drives without hot-swap support. Hot-swap systems integrate mechanisms like interrupt handling and driver support to maintain data integrity during component changes, whereas cold-swap relies on complete power-off states to ensure safe hardware transitions.

Common Use Cases for Hot-Swap

Hot-swap technology is commonly used in data centers and server environments where continuous uptime is critical, allowing hardware components like hard drives, power supplies, or memory modules to be replaced without shutting down the system. It is essential in enterprise storage solutions, enabling quick maintenance and minimizing downtime during hardware failures or upgrades. Hot-swap drives also play a key role in RAID arrays, ensuring data integrity and system reliability while components are replaced on-the-fly.

Typical Applications of Cold-Swap

Cold-swap technology is typically used in applications where hardware components need to be replaced or installed while the system is powered off, such as in desktops, servers, and industrial equipment maintenance. This approach minimizes the risk of data corruption or electrical damage in environments lacking hot-swap support. Your system's design often dictates whether cold-swap is appropriate, especially for critical infrastructure requiring controlled shutdowns before component changes.

Benefits of Implementing Hot-Swap

Hot-swap technology enables the replacement or addition of components such as hard drives, power supplies, or memory modules without shutting down the system, ensuring continuous operation and minimizing downtime. This capability enhances system availability and reliability, particularly in mission-critical environments like data centers and enterprise servers. Implementing hot-swap reduces maintenance costs and improves operational efficiency by allowing upgrades and repairs without interrupting workflows.

Limitations and Risks of Cold-Swap

Cold-swap operations involve powering down the system before replacing or adding components, which can lead to extended downtime and interruptions in critical workflows. The primary limitations include increased risk of data loss and hardware damage due to improper shutdown or static discharge during handling. Understanding these risks helps you plan maintenance windows more effectively to minimize operational disruptions.

Choosing Between Hot-Swap and Cold-Swap

Choosing between hot-swap and cold-swap depends on system requirements and downtime tolerance. Hot-swap allows hardware replacement without shutting down the system, ideal for servers and mission-critical applications needing continuous uptime. Cold-swap requires powering down, suitable for less time-sensitive environments where hardware compatibility and safety are prioritized.

Future Trends in Swappable Technology

Future trends in swappable technology emphasize increased adoption of hot-swap capabilities across data centers and consumer electronics, driven by the demand for minimal downtime and enhanced system availability. Advances in hardware design and standardized connectors, such as USB-C and PCIe 5.0, enable seamless integration and faster hot-swapping processes. Emerging innovations like predictive maintenance using AI and IoT sensors further optimize swappable components by anticipating failures before cold-swap interventions become necessary.

Hot-swap vs Cold-swap Infographic

libmatt.com

libmatt.com