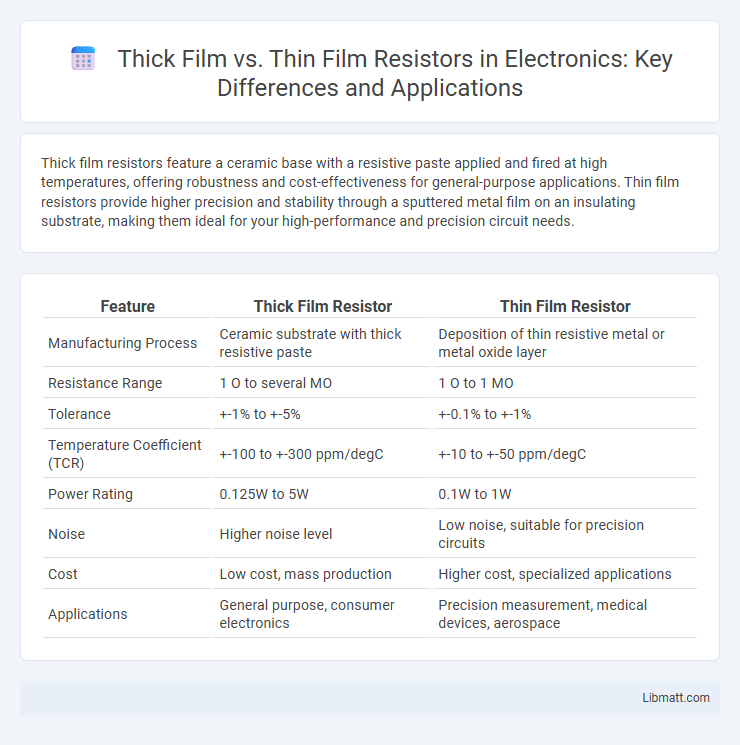

Thick film resistors feature a ceramic base with a resistive paste applied and fired at high temperatures, offering robustness and cost-effectiveness for general-purpose applications. Thin film resistors provide higher precision and stability through a sputtered metal film on an insulating substrate, making them ideal for your high-performance and precision circuit needs.

Table of Comparison

| Feature | Thick Film Resistor | Thin Film Resistor |

|---|---|---|

| Manufacturing Process | Ceramic substrate with thick resistive paste | Deposition of thin resistive metal or metal oxide layer |

| Resistance Range | 1 O to several MO | 1 O to 1 MO |

| Tolerance | +-1% to +-5% | +-0.1% to +-1% |

| Temperature Coefficient (TCR) | +-100 to +-300 ppm/degC | +-10 to +-50 ppm/degC |

| Power Rating | 0.125W to 5W | 0.1W to 1W |

| Noise | Higher noise level | Low noise, suitable for precision circuits |

| Cost | Low cost, mass production | Higher cost, specialized applications |

| Applications | General purpose, consumer electronics | Precision measurement, medical devices, aerospace |

Introduction to Resistors: Thick Film vs Thin Film

Thick film resistors are made by depositing a paste of metal oxides onto a ceramic substrate, offering cost-effective solutions with moderate precision and stability. Thin film resistors use a vapor deposition process to apply a thin layer of resistive material on an insulating substrate, providing higher accuracy, better thermal stability, and lower noise. The choice between thick film and thin film resistors depends on application requirements such as tolerance, power rating, and environmental stability.

Fundamental Differences Between Thick and Thin Film Resistors

Thick film resistors are constructed by screen-printing a resistive paste onto a ceramic substrate, resulting in a thicker resistive layer, whereas thin film resistors use sputtering or vapor deposition to apply a much thinner resistive metal layer. Thick film resistors typically offer higher power ratings and better resistance to environmental factors but exhibit less precision and stability compared to thin film resistors, which provide superior tolerance, noise performance, and temperature coefficients. The choice between thick and thin film resistors depends on application requirements such as accuracy, power dissipation, and cost constraints.

Structure and Manufacturing Processes

Thick film resistors consist of a ceramic substrate coated with a paste containing conductive particles that are screen-printed and fired at high temperatures, creating a robust and cost-effective layer. Thin film resistors use a much thinner, uniform metal or metal-oxide layer deposited on an insulating substrate through vacuum sputtering or evaporation, offering superior precision and stability. Your choice depends on the required performance, as thick film resistors excel in durability and low cost while thin film resistors provide higher accuracy and lower noise due to their refined manufacturing process.

Electrical Properties and Performance Comparison

Thick film and thin film resistors differ significantly in electrical properties and performance, with thin film resistors offering superior precision, lower noise, and better stability due to their uniform metal film deposition on ceramic substrates. Thick film resistors, made from a conductive paste fired onto an insulating substrate, typically exhibit higher tolerance levels and greater power dissipation but may introduce more noise and drift over time. Your choice between these types should consider the required accuracy, thermal stability, and noise sensitivity of your application to optimize electrical performance.

Tolerance and Stability Analysis

Thick film resistors typically offer tolerance ranges between +-1% and +-5%, while thin film resistors provide tighter tolerances as low as +-0.1%, ensuring higher precision in circuit applications. Thin film resistors exhibit superior stability, maintaining resistance values over temperature variations and time due to their uniform film composition and lower noise characteristics. Choosing thin film resistors enhances Your design reliability where critical tolerance and long-term stability are essential.

Applications in Modern Electronics

Thick film resistors are widely used in power applications and circuit boards due to their high power tolerance and cost-effectiveness, making them ideal for industrial electronics and automotive systems. Thin film resistors provide superior precision, stability, and low noise, which is crucial for high-frequency, aerospace, and medical instrumentation. Your choice between thick film and thin film resistors depends on the specific requirements for accuracy, power handling, and environmental stability in modern electronic devices.

Cost Considerations and Economic Factors

Thick film resistors typically offer lower manufacturing costs due to simpler production processes and bulk material usage, making them economically suitable for high-volume, cost-sensitive applications. Thin film resistors, however, provide higher precision and stability but come with increased material and fabrication expenses that elevate their price. Your choice depends on balancing budget constraints with performance requirements, where thick film resistors optimize cost efficiency and thin film resistors justify investment through superior electrical characteristics.

Reliability and Longevity in Circuits

Thick film resistors exhibit high reliability due to their robust construction and ability to withstand thermal stress, making them suitable for general-purpose applications with moderate longevity requirements. Thin film resistors offer superior precision and stability with low temperature coefficients, ensuring consistent performance and longer lifespan in high-frequency and precision circuits. Selecting between thick film and thin film resistors depends on the specific circuit demands for reliability and component longevity.

Environmental and Thermal Characteristics

Thick film resistors exhibit greater robustness in harsh environmental conditions, offering improved moisture resistance and stability under thermal cycling compared to thin film resistors. Thin film resistors provide superior thermal performance with lower temperature coefficients of resistance (TCR), enabling precise stability and minimal resistance drift at elevated temperatures. When selecting a resistor, consider your application's specific environmental exposure and thermal requirements to ensure optimal reliability and performance.

Choosing the Right Resistor Type for Your Project

Thick film resistors offer cost-effective solutions with higher power ratings and better durability, making them suitable for general-purpose applications, while thin film resistors provide superior precision and stability, ideal for high-frequency circuits and sensitive electronic devices. Your choice depends on project requirements such as tolerance, temperature coefficient, and power dissipation. Selecting the right resistor type ensures optimal performance and longevity in your electronic design.

Thick Film vs Thin Film Resistor Infographic

libmatt.com

libmatt.com