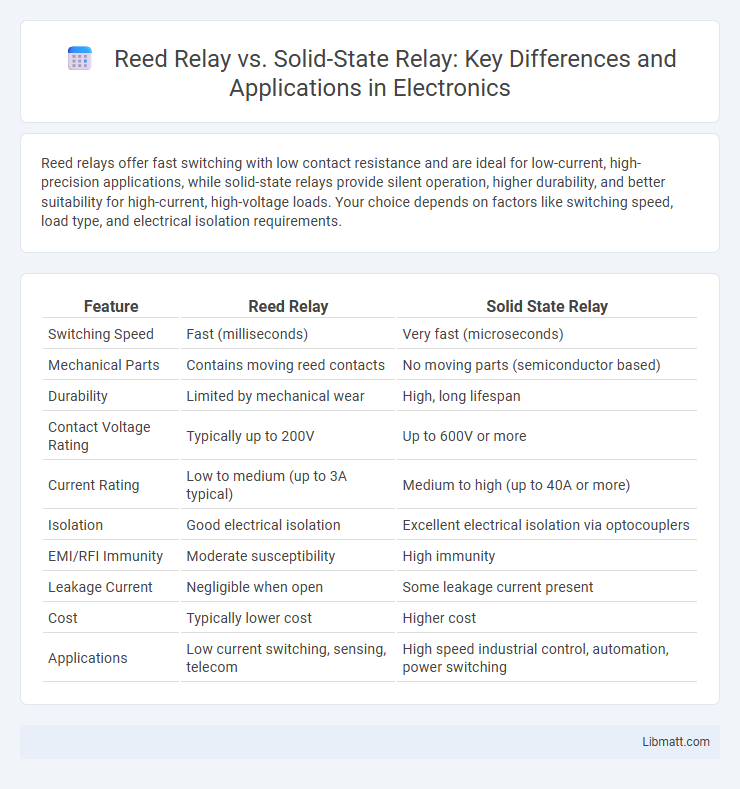

Reed relays offer fast switching with low contact resistance and are ideal for low-current, high-precision applications, while solid-state relays provide silent operation, higher durability, and better suitability for high-current, high-voltage loads. Your choice depends on factors like switching speed, load type, and electrical isolation requirements.

Table of Comparison

| Feature | Reed Relay | Solid State Relay |

|---|---|---|

| Switching Speed | Fast (milliseconds) | Very fast (microseconds) |

| Mechanical Parts | Contains moving reed contacts | No moving parts (semiconductor based) |

| Durability | Limited by mechanical wear | High, long lifespan |

| Contact Voltage Rating | Typically up to 200V | Up to 600V or more |

| Current Rating | Low to medium (up to 3A typical) | Medium to high (up to 40A or more) |

| Isolation | Good electrical isolation | Excellent electrical isolation via optocouplers |

| EMI/RFI Immunity | Moderate susceptibility | High immunity |

| Leakage Current | Negligible when open | Some leakage current present |

| Cost | Typically lower cost | Higher cost |

| Applications | Low current switching, sensing, telecom | High speed industrial control, automation, power switching |

Introduction to Reed Relay and Solid State Relay

Reed relays use magnetic reed switches encapsulated in a glass envelope, offering rapid switching and low contact resistance ideal for sensitive electronics. Solid State Relays (SSRs) employ semiconductor components like thyristors or transistors to switch electrical loads without mechanical parts, ensuring silent operation and high durability. Both relay types serve distinct applications, with reed relays favored in precision signal switching and SSRs preferred for high-speed, high-frequency power control.

Key Functional Differences

Reed relays use electromagnetic coils to physically close contacts made of ferromagnetic reeds, providing low contact resistance and high isolation, ideal for switching low-level signals. Solid state relays operate through semiconductor devices like TRIACs or transistors, offering faster switching speeds, longer lifespans, and enhanced resistance to mechanical wear without physical contacts. Key functional differences include contact type--mechanical in reed relays versus electronic in solid state--and their impact on switching speed, reliability, and signal integrity.

Construction and Working Principles

Reed relays feature hermetically sealed reed switches with magnetic reeds that mechanically open or close contacts in response to an electromagnetic coil, offering fast switching and high isolation. Solid-state relays utilize semiconductor components like TRIACs or MOSFETs to switch loads electronically without moving parts, enhancing durability and silent operation. The mechanical movement in reed relays contrasts with the purely electronic switching in solid-state relays, influencing their applications in terms of speed, longevity, and electrical noise.

Switching Speed Comparison

Reed relays typically offer switching speeds in the range of 0.5 to 1 millisecond, making them suitable for applications requiring fast mechanical switching with low contact capacitance. Solid state relays provide faster switching speeds, often in microseconds, due to their semiconductor-based operation, which eliminates mechanical movement and contact bounce. The choice between reed and solid state relays hinges on the needed switching speed and the trade-offs between mechanical durability and electrical noise.

Electrical Isolation Features

Reed relays provide superior electrical isolation through their hermetically sealed contacts, preventing contamination and ensuring minimal leakage current, which is ideal for sensitive signal switching. Solid state relays offer electrical isolation via an optocoupler or transformer, eliminating mechanical wear but may introduce higher leakage currents and limited voltage isolation compared to reed relays. Your choice depends on the required isolation voltage ratings and the sensitivity of the application's electrical signals.

Power Consumption Analysis

Reed relays exhibit lower power consumption during operation due to their mechanical switching mechanism requiring minimal coil current, typically around 30-60 mW. Solid state relays consume more power continuously, often ranging from 300-500 mW, because their electronic components need constant biasing. Efficiency in low-power applications favors reed relays, while solid state relays provide faster switching at the expense of higher energy usage.

Durability and Longevity

Reed relays offer exceptional durability with a lifespan of up to 500 million cycles due to their hermetically sealed contacts protected from contamination and oxidation. Solid state relays (SSRs) provide longer operational longevity in harsh environments since they lack mechanical parts and are resistant to vibration and shock, often surpassing 100 million cycles. Your choice depends on the application's need for mechanical isolation versus extended lifespan under continuous or high-speed switching conditions.

Application Suitability

Reed relays excel in low-level signal switching, precision measurement, and telecommunications due to their fast response time and low contact resistance. Solid state relays (SSRs) are ideal for high-power applications, industrial automation, and environments requiring high durability and electrical isolation without mechanical wear. Choosing between reed and solid state relays depends on the application's voltage, current load, switching speed, and environmental conditions.

Cost and Maintenance Considerations

Reed relays typically cost more upfront due to their precise mechanical components but require less maintenance because of their simple construction. Solid state relays usually offer a lower initial price and benefit from no moving parts, resulting in minimal maintenance needs and longer operational life. Your choice depends on balancing initial cost with the reliability and maintenance demands specific to your application.

Choosing the Right Relay for Your Project

When choosing the right relay for your project, consider that reed relays excel in fast switching and low current applications due to their hermetically sealed contacts and minimal contact bounce. Solid state relays, on the other hand, offer longer life and silent operation, making them ideal for high-frequency switching and higher power circuits without mechanical wear. Evaluate your project's voltage, current requirements, switching speed, and environmental conditions to determine whether the precision of reed relays or the durability of solid state relays best suits your needs.

Reed Relay vs Solid State Relay Infographic

libmatt.com

libmatt.com