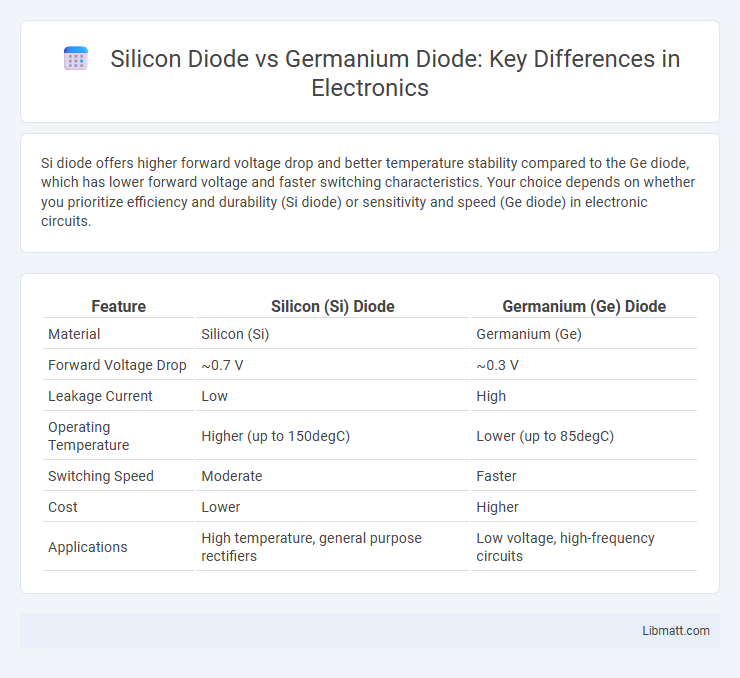

Si diode offers higher forward voltage drop and better temperature stability compared to the Ge diode, which has lower forward voltage and faster switching characteristics. Your choice depends on whether you prioritize efficiency and durability (Si diode) or sensitivity and speed (Ge diode) in electronic circuits.

Table of Comparison

| Feature | Silicon (Si) Diode | Germanium (Ge) Diode |

|---|---|---|

| Material | Silicon (Si) | Germanium (Ge) |

| Forward Voltage Drop | ~0.7 V | ~0.3 V |

| Leakage Current | Low | High |

| Operating Temperature | Higher (up to 150degC) | Lower (up to 85degC) |

| Switching Speed | Moderate | Faster |

| Cost | Lower | Higher |

| Applications | High temperature, general purpose rectifiers | Low voltage, high-frequency circuits |

Introduction to Semiconductor Diodes

Silicon (Si) diodes, made from silicon semiconductor material, offer higher thermal stability and lower leakage current compared to Germanium (Ge) diodes, which have a lower forward voltage drop and faster switching speed. Your choice between Si and Ge diodes depends on application requirements such as operating temperature, efficiency, and signal frequency. Understanding these fundamental differences helps optimize circuit performance in semiconductor diode applications.

Material Properties: Silicon vs Germanium

Silicon diodes offer higher thermal stability and a wider bandgap of 1.1 eV compared to germanium's 0.66 eV, resulting in lower leakage current and better performance at elevated temperatures. Germanium diodes possess higher electron mobility and a lower forward voltage drop around 0.3 V, making them more efficient for low-voltage applications. Your choice between silicon and germanium diodes depends on the balance between temperature tolerance and forward voltage requirements in your electronic circuit design.

Construction Differences

Silicon diodes feature a robust crystal lattice structure with a wider bandgap of approximately 1.1 eV, enabling higher thermal stability and lower leakage currents compared to germanium diodes, which have a narrower bandgap of about 0.66 eV and a more fragile lattice. The silicon diode's PN junction is formed using high-purity, crystalline silicon with a thicker depletion region, while germanium diodes utilize a softer, more conductive material resulting in a thinner depletion region and faster switching times. These construction differences directly influence their electrical characteristics, such as forward voltage drop--roughly 0.7 V for silicon versus 0.3 V for germanium--and temperature sensitivity.

Forward Voltage Drop Comparison

Silicon (Si) diodes typically exhibit a forward voltage drop of approximately 0.7 volts, while Germanium (Ge) diodes have a lower forward voltage drop around 0.3 volts. This significant difference in forward voltage drop influences power efficiency and switching speed in electronic circuits. Engineers prefer Ge diodes for low-voltage applications where minimal voltage loss is critical, whereas Si diodes are more prevalent due to better thermal stability and higher breakdown voltage.

Reverse Leakage Current

Silicon (Si) diodes exhibit significantly lower reverse leakage current compared to Germanium (Ge) diodes due to the wider bandgap of silicon (1.12 eV vs. 0.66 eV for germanium). This lower reverse leakage current in Si diodes enhances their performance in high-temperature and high-frequency applications by reducing power loss and noise. When selecting a diode for your electronic circuits, considering silicon diodes will provide better efficiency and stability in reverse-bias conditions.

Temperature Stability and Performance

Silicon (Si) diodes exhibit superior temperature stability compared to germanium (Ge) diodes, maintaining consistent forward voltage and reducing leakage current over a wide temperature range. Germanium diodes, while offering lower forward voltage drop, experience significant performance degradation and increased leakage at elevated temperatures. This makes silicon diodes more reliable for high-temperature applications and environments requiring stable electrical characteristics.

Application Suitability

Silicon diodes excel in high-temperature and high-voltage applications due to their greater thermal stability and higher forward voltage drop, making them ideal for power rectification and switching circuits. Germanium diodes, with their lower forward voltage drop and faster switching capabilities, are preferred in low-voltage signal detection and radio frequency applications. Your choice depends on whether you need efficiency in high-power environments or sensitivity in low-voltage signal processing.

Cost and Availability

Silicon diodes are generally more cost-effective and widely available due to the abundance of silicon and established manufacturing processes. Germanium diodes tend to be more expensive and less common because germanium is rarer and requires specialized handling. The extensive use of silicon in semiconductor industries ensures better market availability and competitive pricing compared to germanium counterparts.

Advantages and Disadvantages

Silicon (Si) diodes offer higher thermal stability, lower reverse leakage current, and greater durability compared to Germanium (Ge) diodes, making them ideal for high-temperature and high-voltage applications. Germanium diodes provide lower forward voltage drop (around 0.3V) than silicon diodes (approximately 0.7V), which can improve efficiency in low-voltage circuits but suffer from higher leakage current and lower thermal tolerance. Your choice between Si and Ge diodes depends on the specific requirements for efficiency, temperature range, and leakage characteristics in your electronic design.

Summary: Choosing Between Si and Ge Diodes

Silicon (Si) diodes feature higher forward voltage drops around 0.7V and superior thermal stability, making them ideal for standard rectification and high-temperature applications. Germanium (Ge) diodes exhibit lower forward voltage drops near 0.3V, enabling faster switching and better performance in low-voltage circuits but with higher leakage currents and less thermal robustness. Selecting between Si and Ge diodes depends on application requirements such as voltage sensitivity, switching speed, and operating temperature range.

Si Diode vs Ge Diode Infographic

libmatt.com

libmatt.com