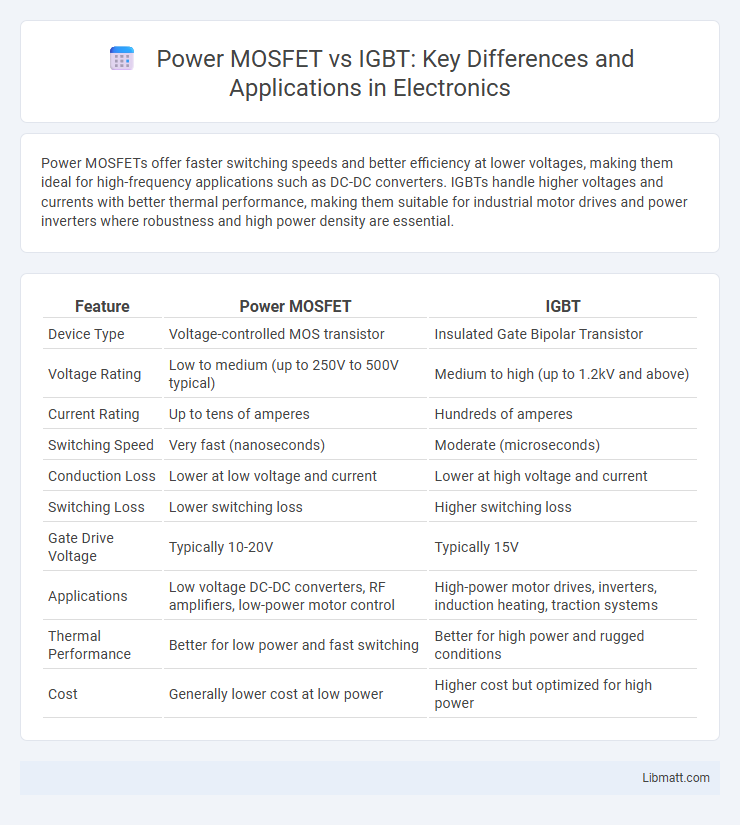

Power MOSFETs offer faster switching speeds and better efficiency at lower voltages, making them ideal for high-frequency applications such as DC-DC converters. IGBTs handle higher voltages and currents with better thermal performance, making them suitable for industrial motor drives and power inverters where robustness and high power density are essential.

Table of Comparison

| Feature | Power MOSFET | IGBT |

|---|---|---|

| Device Type | Voltage-controlled MOS transistor | Insulated Gate Bipolar Transistor |

| Voltage Rating | Low to medium (up to 250V to 500V typical) | Medium to high (up to 1.2kV and above) |

| Current Rating | Up to tens of amperes | Hundreds of amperes |

| Switching Speed | Very fast (nanoseconds) | Moderate (microseconds) |

| Conduction Loss | Lower at low voltage and current | Lower at high voltage and current |

| Switching Loss | Lower switching loss | Higher switching loss |

| Gate Drive Voltage | Typically 10-20V | Typically 15V |

| Applications | Low voltage DC-DC converters, RF amplifiers, low-power motor control | High-power motor drives, inverters, induction heating, traction systems |

| Thermal Performance | Better for low power and fast switching | Better for high power and rugged conditions |

| Cost | Generally lower cost at low power | Higher cost but optimized for high power |

Introduction to Power MOSFET and IGBT

Power MOSFETs are semiconductor devices widely used for fast switching and high-efficiency power management in low to medium voltage applications, offering low on-resistance and high switching speeds. IGBTs combine the benefits of MOSFETs and bipolar transistors, providing high input impedance and strong current-carrying capability, making them ideal for medium to high voltage and power applications. Understanding these fundamental differences helps you select the right device based on your system's voltage, current, and switching frequency requirements.

Operating Principles Explained

Power MOSFETs operate by using an electric field to control the flow of current through a semiconductor channel, enabling fast switching speeds with low gate drive power. IGBTs combine the characteristics of bipolar junction transistors and MOSFETs, utilizing a voltage-controlled gate to switch high currents with lower conduction losses at high voltage levels. The fundamental difference lies in the MOSFET's majority carrier conduction for rapid switching, whereas the IGBT's minority carrier conduction allows for efficient handling of higher voltage and current in power applications.

Key Differences in Structure

Power MOSFETs feature a vertical structure with a metal-oxide-semiconductor gate, enabling fast switching and low gate drive power. IGBTs combine the MOSFET gate structure with a bipolar junction transistor layer, allowing higher voltage and current handling but slower switching speeds. The main structural difference lies in the MOSFET's unipolar conduction versus IGBT's bipolar conduction, impacting their performance and application.

Switching Speed Comparison

Power MOSFETs exhibit significantly faster switching speeds than IGBTs, making them ideal for high-frequency applications such as RF amplifiers and DC-DC converters. MOSFETs can switch in nanoseconds due to their majority carrier operation, whereas IGBTs rely on minority carriers, resulting in slower switching typically in the microsecond range. The reduced switching losses in MOSFETs enhance efficiency in fast-switching power supplies compared to the higher conduction losses usually associated with IGBTs.

Conduction and Switching Losses

Power MOSFETs typically exhibit lower conduction losses due to their majority carrier operation, making them highly efficient at low voltage and high-frequency switching applications. IGBTs, combining bipolar and MOSFET characteristics, generally have higher conduction losses but can handle higher voltage and current levels with better performance in medium- to high-power applications. Switching losses in Power MOSFETs are usually lower at high frequencies, while IGBTs experience greater switching losses because of their tail current during turn-off, impacting efficiency in fast switching scenarios.

Voltage and Current Handling Capabilities

Power MOSFETs excel in fast switching and efficiency at low to medium voltages, typically up to 250 volts, with current handling capabilities suited for high-frequency applications. IGBTs are designed for higher voltage ranges, commonly from 600 volts to several kilovolts, and can handle larger currents, making them ideal for industrial motor drives and heavy-duty power electronics. Your choice between Power MOSFET and IGBT should align with the voltage and current requirements of your specific application to optimize performance and reliability.

Thermal Management and Efficiency

Power MOSFETs exhibit superior thermal conductivity and lower on-resistance, enabling more efficient heat dissipation and higher switching speeds compared to IGBTs. IGBTs are better suited for high-voltage, high-current applications but typically generate more heat due to their slower switching and higher conduction losses. Effective thermal management in both devices directly impacts system efficiency, with MOSFETs offering enhanced performance in low-voltage, high-frequency environments, while IGBTs excel in heavy-duty industrial power conversion.

Typical Applications and Use Cases

Power MOSFETs excel in high-frequency switching applications such as DC-DC converters, power supplies, and motor drives due to their fast switching speed and low on-resistance. IGBTs are preferred in high-voltage, high-current applications like industrial motor control, renewable energy inverters, and electric vehicle traction systems because of their superior conduction efficiency and robustness at higher voltages. Your choice depends on the operating frequency, voltage, and current levels each device can efficiently handle within your specific application.

Cost Considerations and Market Trends

Power MOSFETs generally offer lower initial costs and are favored in low-voltage, high-frequency applications, whereas IGBTs, with higher upfront costs, excel in high-voltage, high-power environments. Market trends reveal increasing integration of Power MOSFETs in consumer electronics due to cost efficiency and efficiency gains, while IGBTs dominate industrial sectors such as renewable energy and electric vehicles driven by their robust performance and thermal stability. Economies of scale and technological advancements continue to narrow the cost gap, influencing adoption rates across various applications.

Choosing the Right Device for Your Application

Power MOSFETs excel in high-speed switching and low-voltage applications below 250V, offering superior efficiency and faster recovery times. IGBTs are better suited for high-voltage, high-current scenarios above 600V, providing robustness and lower conduction losses in industrial motor drives and inverters. Choosing the right device depends on your application's voltage, current requirements, switching frequency, and efficiency priorities.

Power MOSFET vs IGBT Infographic

libmatt.com

libmatt.com