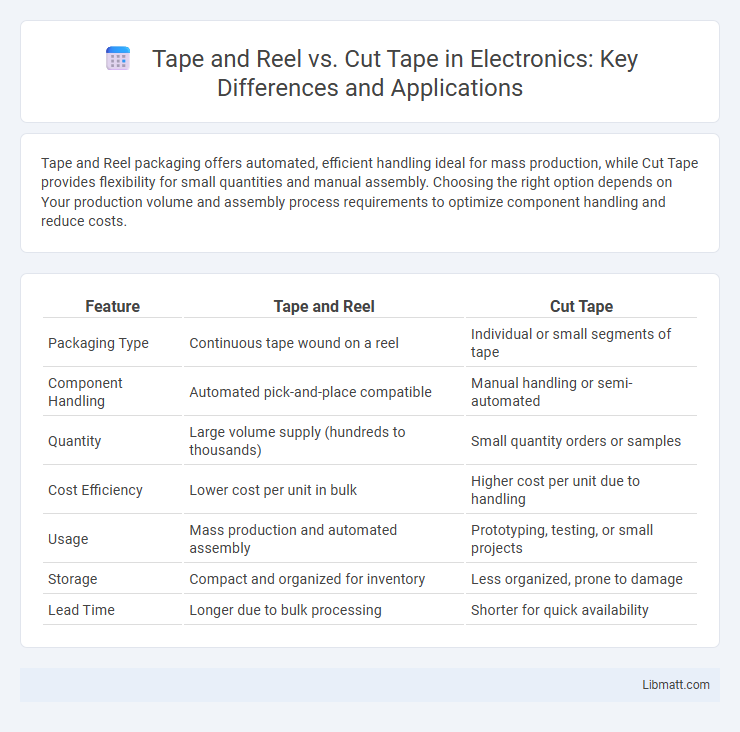

Tape and Reel packaging offers automated, efficient handling ideal for mass production, while Cut Tape provides flexibility for small quantities and manual assembly. Choosing the right option depends on Your production volume and assembly process requirements to optimize component handling and reduce costs.

Table of Comparison

| Feature | Tape and Reel | Cut Tape |

|---|---|---|

| Packaging Type | Continuous tape wound on a reel | Individual or small segments of tape |

| Component Handling | Automated pick-and-place compatible | Manual handling or semi-automated |

| Quantity | Large volume supply (hundreds to thousands) | Small quantity orders or samples |

| Cost Efficiency | Lower cost per unit in bulk | Higher cost per unit due to handling |

| Usage | Mass production and automated assembly | Prototyping, testing, or small projects |

| Storage | Compact and organized for inventory | Less organized, prone to damage |

| Lead Time | Longer due to bulk processing | Shorter for quick availability |

Introduction to Tape and Reel vs Cut Tape

Tape and Reel and Cut Tape are essential packaging methods used in electronic component manufacturing to ensure efficient handling and placement during automated assembly. Tape and Reel involves components being placed on a continuous carrier tape wound on reels, which optimizes automated feeding and reduces handling time. Cut Tape consists of components segmented into smaller, user-friendly strips, suitable for manual assembly or small-scale production runs, making Your choice dependent on production volume and assembly automation needs.

What is Tape and Reel Packaging?

Tape and reel packaging is a standardized method used for storing and delivering electronic components in a continuous strip of embossed carrier tape, wound on a reel. This packaging ensures precise placement and protection of components during automated pick-and-place assembly processes, enhancing manufacturing efficiency and reducing damage risks. You benefit from tape and reel packaging through improved handling, faster assembly times, and minimized component loss compared to cut tape formats.

Understanding Cut Tape Packaging

Cut tape packaging involves individual sections of electronic components separated from the continuous reel, facilitating easy manual handling and prototyping. This format suits low-volume production or testing environments where automatic pick-and-place machines are not used, reducing component waste and simplifying access. Understanding the dimensional standards and carrier tape specifications is essential to ensure compatibility with component types and assembly processes.

Key Differences Between Tape and Reel and Cut Tape

Tape and Reel involves components packaged in a continuous strip wound onto a reel, facilitating automated assembly and efficient handling in high-volume manufacturing. Cut Tape, by contrast, contains individually cut lengths of tape with a fixed number of components, ideal for prototyping or low-volume production where flexibility and easy component access are prioritized. Tape and Reel offers superior protection and automation compatibility, while Cut Tape supports manual processes and smaller batch sizes.

Pros and Cons of Tape and Reel

Tape and reel packaging offers automated assembly compatibility and protects electronic components from damage during transportation, making it ideal for high-volume manufacturing. It reduces handling errors and improves placement accuracy but generally incurs higher initial costs and may require specific equipment for loading. Your choice depends on production scale and automation capabilities, balancing cost-efficiency with operational convenience.

Advantages and Disadvantages of Cut Tape

Cut tape offers advantages such as flexibility in handling small quantities and reduced waste, making it ideal for prototype or low-volume production runs. However, it lacks the automation-friendly benefits of tape and reel packaging, which can increase manual handling time and the risk of component damage or loss. Your choice depends on balancing cost-effectiveness with efficiency requirements in your assembly process.

When to Choose Tape and Reel Packaging

Tape and reel packaging is ideal for automated assembly processes where high-volume component placement speeds up production efficiency and reduces handling errors. Your choice should lean towards tape and reel when dealing with surface-mount devices (SMDs) that require precise, continuous feeding into pick-and-place machines for seamless manufacturing. This packaging method also enhances component protection during transportation and minimizes the risk of damage or contamination compared to cut tape.

Ideal Use Cases for Cut Tape

Cut tape is ideal for low-volume prototyping and repair work where only small quantities of components are needed, reducing waste and storage requirements. It supports quick access to parts without unwinding entire reels, making it efficient for manual assembly and testing environments. This format is commonly preferred by engineers and technicians handling occasional component usage or specialized small-batch production runs.

Cost Comparison: Tape and Reel vs Cut Tape

Tape and Reel packaging generally incurs higher initial costs due to specialized machinery and materials, but it reduces labor expenses through automated component placement, leading to overall savings in high-volume production. Cut Tape often has lower upfront costs and is suitable for small runs or prototyping but increases manual handling time, driving up labor costs in larger volumes. Evaluating total expenses across production scale reveals Tape and Reel as more cost-effective for mass manufacturing, while Cut Tape remains economical for limited quantities.

Making the Right Choice for Your Project

Choosing between Tape and Reel and Cut Tape depends on your project's production volume and handling requirements. Tape and Reel provides efficient automated assembly for large-scale manufacturing, reducing component damage and streamlining the pick-and-place process. Cut Tape suits smaller projects or prototypes by offering flexibility and ease of access to individual components without the need for specialized equipment.

Tape and Reel vs Cut Tape Infographic

libmatt.com

libmatt.com