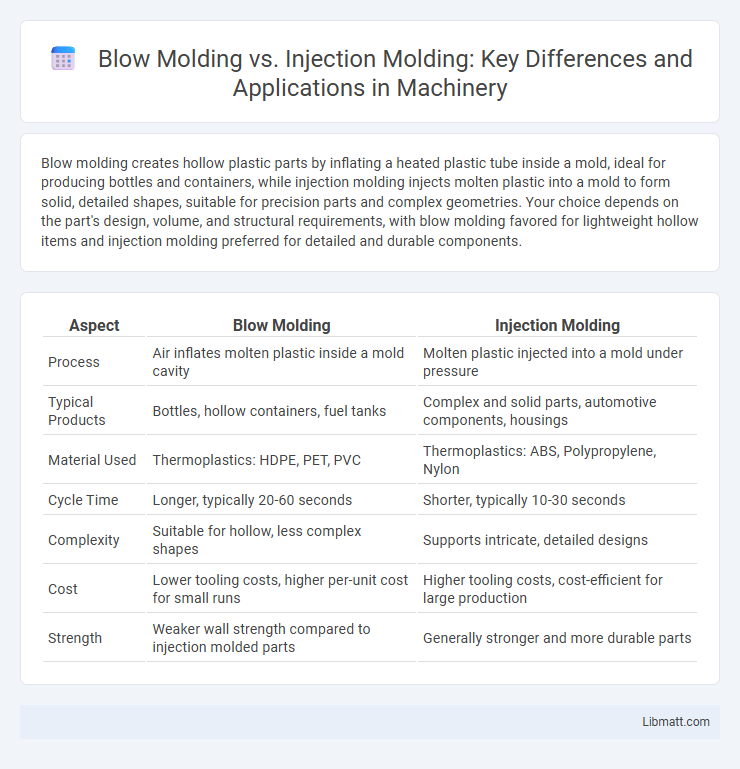

Blow molding creates hollow plastic parts by inflating a heated plastic tube inside a mold, ideal for producing bottles and containers, while injection molding injects molten plastic into a mold to form solid, detailed shapes, suitable for precision parts and complex geometries. Your choice depends on the part's design, volume, and structural requirements, with blow molding favored for lightweight hollow items and injection molding preferred for detailed and durable components.

Table of Comparison

| Aspect | Blow Molding | Injection Molding |

|---|---|---|

| Process | Air inflates molten plastic inside a mold cavity | Molten plastic injected into a mold under pressure |

| Typical Products | Bottles, hollow containers, fuel tanks | Complex and solid parts, automotive components, housings |

| Material Used | Thermoplastics: HDPE, PET, PVC | Thermoplastics: ABS, Polypropylene, Nylon |

| Cycle Time | Longer, typically 20-60 seconds | Shorter, typically 10-30 seconds |

| Complexity | Suitable for hollow, less complex shapes | Supports intricate, detailed designs |

| Cost | Lower tooling costs, higher per-unit cost for small runs | Higher tooling costs, cost-efficient for large production |

| Strength | Weaker wall strength compared to injection molded parts | Generally stronger and more durable parts |

Introduction to Blow Molding and Injection Molding

Blow molding and injection molding are two key manufacturing processes used in producing plastic parts with high precision and efficiency. Blow molding is primarily used for creating hollow objects such as bottles and containers by inflating molten plastic inside a mold, while injection molding involves injecting molten plastic into a mold cavity to form solid parts with detailed features. Understanding the differences between these processes helps you select the appropriate method for your product requirements in terms of shape, volume, and material use.

Fundamental Principles of Each Molding Process

Blow molding shapes hollow plastic parts by inflating a heated parison inside a mold cavity to form uniform walls, commonly used for bottles and containers. Injection molding involves injecting molten plastic into a mold cavity under high pressure, cooling to solidify complex, detailed parts with high precision. Understanding these fundamental principles helps you select the optimal process based on part geometry, wall thickness, and production volume requirements.

Material Compatibility and Selection

Blow molding is ideal for thermoplastic materials such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), offering excellent flexibility for hollow parts like bottles. Injection molding accommodates a broader range of materials, including thermoplastics, thermosets, and elastomers, providing high precision and material strength in complex solid components. Your choice between blow molding and injection molding depends heavily on the material properties required for the final product's durability, flexibility, and design complexity.

Design Flexibility and Product Complexity

Blow molding offers greater design flexibility for hollow products such as bottles and containers, allowing for variable wall thickness and seamless shapes with complex curves. Injection molding excels in producing highly detailed and intricate parts with tight tolerances, suitable for complex geometries and multi-component assemblies. Your choice depends on the desired product complexity and whether the part requires hollow or solid structures.

Production Speed and Cycle Time Comparison

Blow molding typically offers faster production speeds for hollow plastic parts, with cycle times ranging from a few seconds to under a minute, making it ideal for high-volume bottle manufacturing. Injection molding, while often having longer cycle times due to cooling and solidification processes, excels in producing complex, precise geometries with rapid multi-cavity setups that can reduce overall production duration. Your choice between blow molding and injection molding should depend on the balance between the required part complexity and the desired production speed.

Cost Considerations: Tooling, Production, and Maintenance

Blow molding typically involves lower initial tooling costs compared to injection molding, making it ideal for high-volume hollow part production with less complex molds. Injection molding requires higher upfront tooling investment due to intricate mold designs but offers faster cycle times and lower per-unit production costs for detailed solid components. Maintenance expenses for blow molding are generally lower due to simpler machinery, whereas injection molding machines demand more frequent upkeep to maintain precision and quality.

Strengths and Limitations of Blow Molding

Blow molding excels in producing hollow plastic parts with uniform wall thickness, ideal for containers, bottles, and fuel tanks, offering cost-effective manufacturing for large volumes. Its limitations include less precision in detailed features and surface finish compared to injection molding, as well as limited material options primarily favoring thermoplastics like HDPE and PET. Blow molding is less suitable for intricate designs or small, solid parts, where injection molding provides superior dimensional accuracy and design flexibility.

Advantages and Drawbacks of Injection Molding

Injection molding offers high precision and excellent surface finish, making it ideal for producing complex and detailed parts in large volumes with consistent quality. The process has a fast cycle time and supports a wide range of materials, but the high initial mold cost and longer setup time can be drawbacks for low-volume production. Your choice depends on balancing these factors with product complexity, production volume, and budget constraints.

Typical Applications and Industry Use Cases

Blow molding is ideal for manufacturing hollow plastic products such as bottles, containers, and fuel tanks, commonly used in the packaging, automotive, and consumer goods industries. Injection molding excels in producing complex, high-precision parts like automotive components, medical devices, and electronic housings, offering versatility for high-volume manufacturing. Your choice between blow molding and injection molding depends on the product design, material requirements, and industry-specific applications.

Choosing the Right Molding Technique for Your Project

Blow molding excels in creating hollow plastic products such as bottles and containers, offering cost-effective production for large volumes with uniform wall thickness. Injection molding provides precise, intricate designs suited for solid parts, delivering high dimensional accuracy and faster cycle times for complex geometries. Selecting the right molding technique depends on product design, volume requirements, material characteristics, and cost considerations, ensuring optimal manufacturing efficiency and quality.

Blow molding vs injection molding Infographic

libmatt.com

libmatt.com