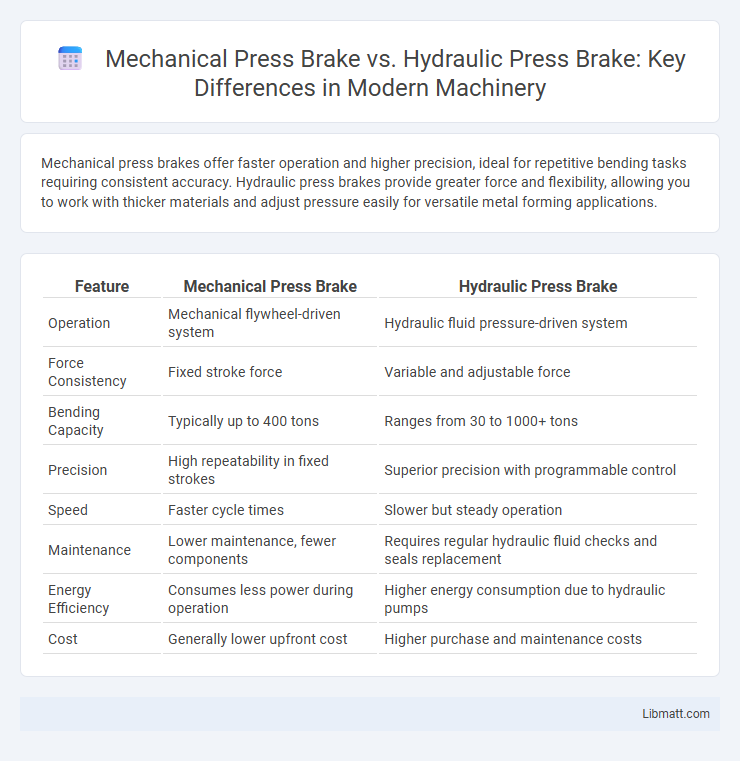

Mechanical press brakes offer faster operation and higher precision, ideal for repetitive bending tasks requiring consistent accuracy. Hydraulic press brakes provide greater force and flexibility, allowing you to work with thicker materials and adjust pressure easily for versatile metal forming applications.

Table of Comparison

| Feature | Mechanical Press Brake | Hydraulic Press Brake |

|---|---|---|

| Operation | Mechanical flywheel-driven system | Hydraulic fluid pressure-driven system |

| Force Consistency | Fixed stroke force | Variable and adjustable force |

| Bending Capacity | Typically up to 400 tons | Ranges from 30 to 1000+ tons |

| Precision | High repeatability in fixed strokes | Superior precision with programmable control |

| Speed | Faster cycle times | Slower but steady operation |

| Maintenance | Lower maintenance, fewer components | Requires regular hydraulic fluid checks and seals replacement |

| Energy Efficiency | Consumes less power during operation | Higher energy consumption due to hydraulic pumps |

| Cost | Generally lower upfront cost | Higher purchase and maintenance costs |

Introduction to Press Brakes

Press brakes are essential machines in metal fabrication, used to bend sheet metal into precise shapes and angles. Mechanical press brakes utilize a flywheel and clutch system for rapid, consistent bending, making them ideal for high-volume production with lighter gauge materials. Hydraulic press brakes rely on hydraulic cylinders for adjustable pressure and slower, more controlled bends, offering versatility for thicker materials and complex bending tasks.

Overview of Mechanical Press Brakes

Mechanical press brakes utilize a flywheel system powered by an electric motor, delivering consistent bending force at high speeds, ideal for repetitive sheet metal forming tasks. They offer precise stroke control and rapid cycle times, making them suitable for production environments requiring accuracy and efficiency. Compared to hydraulic press brakes, mechanical models typically provide faster operation but may have limitations in bending force flexibility and energy efficiency.

Overview of Hydraulic Press Brakes

Hydraulic press brakes utilize a hydraulic system powered by fluid pressure to exert force on metal sheets, allowing precise bending and shaping. These machines offer greater versatility and consistent tonnage throughout the stroke, making them suitable for heavy-duty and complex bending tasks in industries like automotive and aerospace. The ability to control ram speed and pressure accurately enhances precision and reduces material waste compared to mechanical press brakes.

Key Differences Between Mechanical and Hydraulic Press Brakes

Mechanical press brakes operate using a flywheel and clutch system, providing high-speed, precise pressing ideal for small to medium production runs, while hydraulic press brakes use hydraulic cylinders, offering greater force, slower operation, and flexibility for handling thicker and heavier materials. Mechanical models excel in fast, repetitive tasks with consistent stroke lengths, whereas hydraulic press brakes allow adjustable tonnage and stroke, making them versatile for complex bending operations. Maintenance for mechanical press brakes tends to be simpler due to fewer hydraulic components, but hydraulic systems deliver smoother pressure control and higher tonnage capabilities.

Precision and Accuracy Comparison

Mechanical press brakes deliver higher precision and repeatability due to their rigid frame and mechanical linkages, enabling consistent bending angles with less deviation. Hydraulic press brakes offer flexibility in pressure control but may experience slight variations in accuracy because of fluid compressibility and potential leakage. For applications demanding tight tolerances and exact bend angles, mechanical press brakes typically outperform hydraulic models in precision and accuracy.

Speed and Efficiency Analysis

Mechanical press brakes operate at higher speeds with rapid stroke rates, making them ideal for high-volume production where efficiency is critical. Hydraulic press brakes provide precise control and consistent bending force, which enhances accuracy but results in slower cycles compared to mechanical models. Your choice depends on whether speed or precision drives your manufacturing priorities.

Maintenance and Durability Considerations

Mechanical press brakes Require less maintenance due to their simpler, mechanical components, resulting in longer service intervals and lower downtime costs. Hydraulic press brakes offer smoother operation and greater versatility but demand regular hydraulic fluid checks, seal replacements, and system inspections to prevent leaks and maintain optimal performance. Choosing the right press brake for your workshop depends on balancing your need for durability with maintenance availability and operational requirements.

Safety Features and Concerns

Mechanical press brakes offer consistent stroke speed and force, allowing for precise control, but they require robust safety guards and emergency stop mechanisms to prevent operator injury due to their rapid operation. Hydraulic press brakes provide adjustable tonnage and slower, more controlled movements, which enhance safety by minimizing sudden machine motions and reducing risk during complex bends. Your choice should consider the specific safety features such as light curtains, pressure-sensitive mats, and safety interlocks to ensure optimal protection in your fabrication setup.

Cost and Investment Factors

Mechanical press brakes typically have higher upfront costs due to their complex flywheel and clutch systems, but they offer lower operating expenses with reduced energy consumption and minimal maintenance. Hydraulic press brakes come with a lower initial investment and provide greater versatility in bending thicker materials, though they incur increased operational costs stemming from hydraulic fluid maintenance and potential leak repairs. Choosing between the two depends on long-term production volume, material thickness requirements, and maintenance budget considerations.

Choosing the Right Press Brake for Your Application

Mechanical press brakes offer faster cycle times and high precision, ideal for high-volume production with consistent bending requirements. Hydraulic press brakes provide greater tonnage capacity and adjustable ram speed, making them better suited for heavy-duty and complex bending tasks. Evaluating your specific material thickness, production volume, and precision needs will help you choose the right press brake to optimize efficiency and quality in your metal forming operations.

Mechanical press brake vs hydraulic press brake Infographic

libmatt.com

libmatt.com