Gear shaping and gear hobbing are essential methods for cutting gears, with gear shaping using a reciprocating cutter to create internal and external gears, while gear hobbing employs a rotating hob to generate gears more efficiently. Your choice depends on the gear type and production volume, as hobbing excels in high-volume manufacturing and shaping suits complex or internal gears.

Table of Comparison

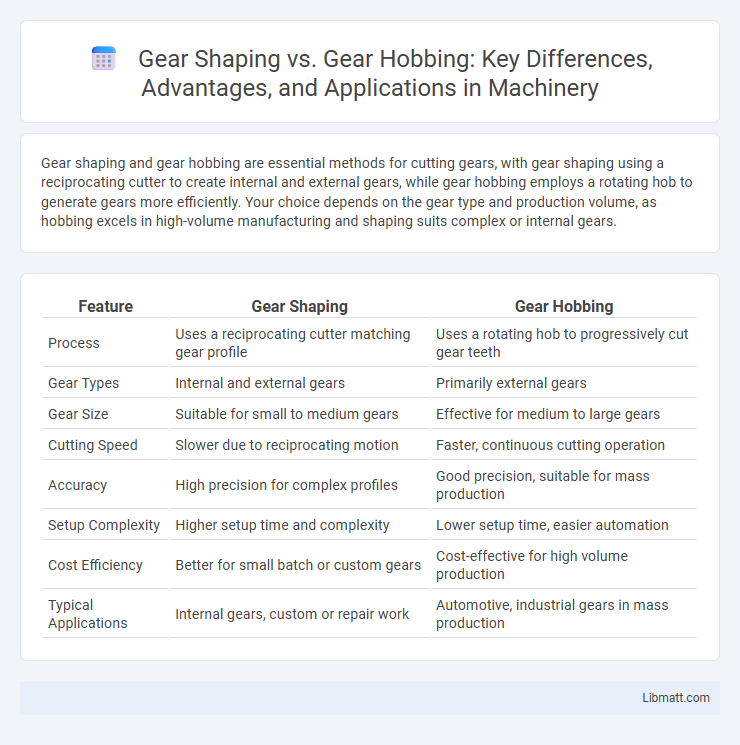

| Feature | Gear Shaping | Gear Hobbing |

|---|---|---|

| Process | Uses a reciprocating cutter matching gear profile | Uses a rotating hob to progressively cut gear teeth |

| Gear Types | Internal and external gears | Primarily external gears |

| Gear Size | Suitable for small to medium gears | Effective for medium to large gears |

| Cutting Speed | Slower due to reciprocating motion | Faster, continuous cutting operation |

| Accuracy | High precision for complex profiles | Good precision, suitable for mass production |

| Setup Complexity | Higher setup time and complexity | Lower setup time, easier automation |

| Cost Efficiency | Better for small batch or custom gears | Cost-effective for high volume production |

| Typical Applications | Internal gears, custom or repair work | Automotive, industrial gears in mass production |

Overview of Gear Shaping and Gear Hobbing

Gear shaping and gear hobbing are two essential machining processes used to manufacture gears with precision and efficiency. Gear shaping uses a reciprocating cutter that shapes the gear teeth by cutting in a linear motion, ideal for internal gears and complex forms, while gear hobbing employs a rotating hob to continuously cut gear teeth, suited for high-volume production of external gears. Your choice between gear shaping and gear hobbing depends on factors such as gear type, production volume, and required accuracy.

Fundamental Principles of Gear Shaping

Gear shaping operates on the fundamental principle of using a rotating cutting tool that reciprocates axially, matching the gear blank's rotation to generate accurate tooth profiles through a continuous cutting motion. This method relies on the generated gear tooth shaping process, where both the cutter and gear blank maintain a precise relative angular velocity ratio to form each tooth progressively. Your gear shaping process ensures high precision for internal and external gears, especially useful for complex gear geometries not easily produced by gear hobbing.

Fundamental Principles of Gear Hobbing

Gear hobbing operates on the principle of continuous generating, where a cylindrical cutting tool called a hob rotates in synchronization with a blank gear, progressively cutting gear teeth through a helical motion. The hob's design, featuring multiple cutting edges arranged in a helical pattern, allows efficient material removal and high precision in forming involute gear profiles. This method is highly suitable for producing spur, helical, and worm gears with consistent accuracy and surface finish.

Key Differences Between Gear Shaping and Hobbing

Gear shaping uses a reciprocating cutter that resembles a gear, generating internal and external gears, while gear hobbing employs a rotating hob to progressively cut gear teeth on a workpiece. Gear shaping is ideal for internal gears and small batch production, whereas gear hobbing excels in high-volume manufacturing and external gear fabrication. Your choice depends on the gear type, production volume, and precision requirements.

Advantages of Gear Shaping

Gear shaping offers superior precision in creating internal and external gears, making it ideal for complex gear profiles and tight tolerances. Your manufacturing process benefits from its capability to machine both small and large gears with consistent accuracy. Compared to gear hobbing, gear shaping provides enhanced flexibility for producing internal gears and allows for efficient gear cutting in limited spaces.

Advantages of Gear Hobbing

Gear hobbing offers higher efficiency and faster production rates compared to gear shaping, making it ideal for high-volume manufacturing. It allows for versatile gear types including spur, helical, and worm gears, providing broad application flexibility. The continuous cutting process in gear hobbing results in smoother gear surfaces and improved dimensional accuracy.

Limitations of Each Gear Cutting Method

Gear shaping is limited by slower production rates and difficulty in cutting external gears with large diameters, while gear hobbing cannot effectively cut internal gears and may struggle with gears having very small modules. Your choice depends on the specific gear geometry and production volume required. Both methods have constraints in precision for complex gear profiles and hardness of the material.

Typical Applications for Gear Shaping and Hobbing

Gear shaping excels in producing internal gears, splines, and small to medium-sized external gears with complex profiles, making it ideal for automotive transmissions and aerospace components. Gear hobbing is preferred for high-volume manufacturing of external spur, helical, and worm gears, commonly used in heavy machinery, industrial gearboxes, and agricultural equipment. Both methods support precision gear production, but gear shaping offers greater flexibility for intricate and internal gear geometries.

Material and Gear Type Compatibility

Gear shaping excels with internal gears and gears made from softer materials like brass or aluminum, offering precision without extensive setup changes. Gear hobbing suits a wide range of external gear types and harsher materials, including steel and hardened alloys, enabling versatility in production. Your choice between these processes depends on the gear geometry and the material to ensure optimal manufacturing efficiency and quality.

Choosing the Right Gear Manufacturing Process

Choosing the right gear manufacturing process depends on factors such as gear type, production volume, and accuracy requirements. Gear shaping is ideal for internal gears and specialized profiles, offering precise and cost-effective solutions for smaller batches, while gear hobbing excels in producing external gears rapidly with high consistency in large-scale manufacturing. Understanding your specific gear design and application needs ensures optimal efficiency and quality in gear production.

Gear shaping vs gear hobbing Infographic

libmatt.com

libmatt.com