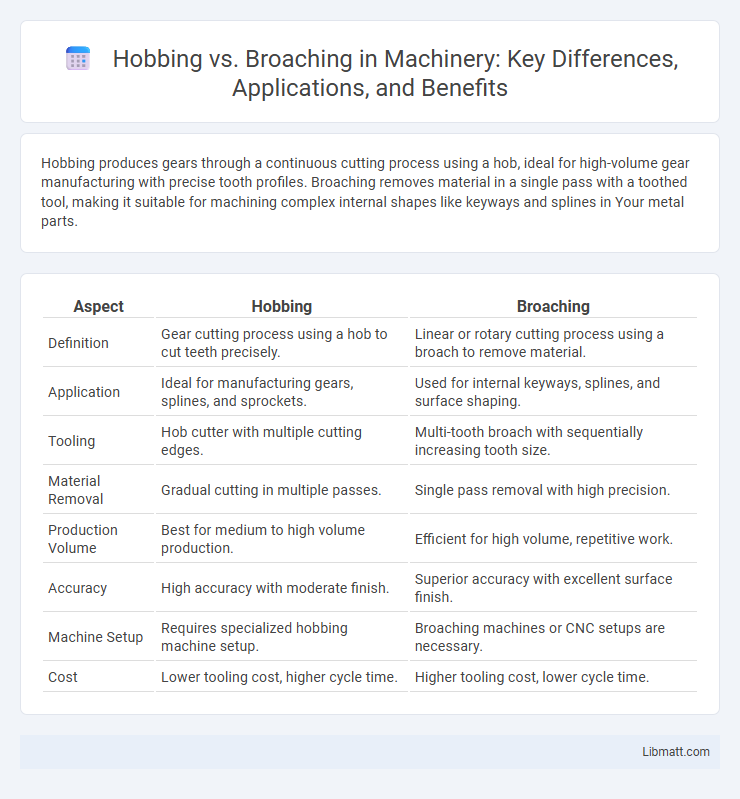

Hobbing produces gears through a continuous cutting process using a hob, ideal for high-volume gear manufacturing with precise tooth profiles. Broaching removes material in a single pass with a toothed tool, making it suitable for machining complex internal shapes like keyways and splines in Your metal parts.

Table of Comparison

| Aspect | Hobbing | Broaching |

|---|---|---|

| Definition | Gear cutting process using a hob to cut teeth precisely. | Linear or rotary cutting process using a broach to remove material. |

| Application | Ideal for manufacturing gears, splines, and sprockets. | Used for internal keyways, splines, and surface shaping. |

| Tooling | Hob cutter with multiple cutting edges. | Multi-tooth broach with sequentially increasing tooth size. |

| Material Removal | Gradual cutting in multiple passes. | Single pass removal with high precision. |

| Production Volume | Best for medium to high volume production. | Efficient for high volume, repetitive work. |

| Accuracy | High accuracy with moderate finish. | Superior accuracy with excellent surface finish. |

| Machine Setup | Requires specialized hobbing machine setup. | Broaching machines or CNC setups are necessary. |

| Cost | Lower tooling cost, higher cycle time. | Higher tooling cost, lower cycle time. |

Introduction to Hobbing and Broaching

Hobbing is a precision machining process used to create gears through a specialized cutting tool called a hob, enabling efficient production of high-quality gear teeth. Broaching involves a linear cutting motion using a toothed tool, ideal for producing keyways, splines, and other precise internal or external profiles with excellent surface finish. Understanding the differences in tooling and applications helps you select the best method for your specific machining needs.

Overview of the Hobbing Process

Hobbing is a precise gear manufacturing process involving a specialized cutting tool called a hob, which rotates continuously while the workpiece turns in synchronization to create gear teeth. This method allows for efficient production of high-quality gears with consistent tooth profiles, making it ideal for medium to large batch runs. Your choice of hobbing ensures accuracy and repeatability in gear cutting compared to other methods like broaching, which uses a linear pull to morph the gear shape.

Overview of the Broaching Process

Broaching is a machining process that uses a toothed tool called a broach to remove material efficiently, often used for precision shaping of internal or external surfaces. The broach tool moves linearly or rotary relative to the workpiece, progressively cutting away material with each tooth to achieve complex shapes or fine finishes. This process is favored for its high accuracy, repeatability, and ability to create keyways, splines, and intricate profiles in metals and other materials.

Key Differences Between Hobbing and Broaching

Hobbing and broaching differ primarily in their machining processes and applications; hobbing uses a rotating hob to cut gears while broaching involves a toothed tool pulled or pushed through a workpiece to remove material. Hobbing is ideal for producing gears with high precision and efficiency, especially in volumes, whereas broaching excels at creating complex internal shapes like keyways or splines with tight tolerances. Your choice between these methods depends on the desired part geometry, production speed, and precision requirements.

Types of Gears Produced: Hobbing vs Broaching

Hobbing is primarily used to produce spur, helical, worm, and bevel gears with high precision and efficiency, making it ideal for moderate to large production runs. Broaching excels in manufacturing internal gears and splines, offering tight tolerances and smooth surface finishes suitable for complex internal profiles. Your choice between hobbing and broaching will depend on whether you need external gear types or intricate internal gear formations.

Material Compatibility in Hobbing and Broaching

Hobbing is highly compatible with a wide range of materials including various steels, cast irons, and non-ferrous metals, making it ideal for manufacturing complex gears with high precision. Broaching excels in processing softer materials such as aluminum, brass, and plastics but can also handle hardened steels, especially in applications requiring internal keyways or splines. Material selection in both processes impacts tool life and surface finish quality, with hobbing generally preferred for durable materials and broaching suited for intricate profiles in softer components.

Accuracy and Surface Finish Comparison

Hobbing achieves moderate accuracy with typical tolerances around +-0.01 mm, suitable for producing gears with consistent tooth geometry, while broaching delivers higher precision, often within +-0.005 mm, ideal for intricate internal shapes. Surface finish from broaching generally outperforms hobbing, producing smoother surfaces with roughness values as low as Ra 0.4 um compared to hobbing's typical Ra of 1.6 um. The superior accuracy and finer surface finish of broaching make it preferred for high-precision components, whereas hobbing remains cost-effective and efficient for large-volume gear production.

Production Speed and Cost Efficiency

Hobbing offers faster production speeds for high-volume gear manufacturing due to its continuous cutting process, reducing cycle times significantly compared to broaching. Broaching incurs higher costs for complex broach tool manufacturing and is generally more suited for lower volume, high-precision internal gear finishing. Choosing hobbing enhances cost efficiency in mass production, while broaching remains preferable for specialized, low-volume applications requiring intricate shapes.

Advantages and Disadvantages of Each Method

Hobbing offers high efficiency and versatility in producing gears with complex tooth profiles, making it ideal for large-scale manufacturing, but it can require significant initial setup and specialized equipment. Broaching provides precise and smooth finishes for internal shapes and keyways, with the advantage of consistent accuracy, though it is often limited to specific shapes and can be less cost-effective for small batch production. Your choice depends on whether you prioritize high-volume gear cutting or intricate internal feature machining.

Choosing the Right Process for Your Application

Hobbing and broaching are specialized machining processes used for gear and keyway manufacturing, each offering unique advantages depending on your application requirements. Hobbing excels in producing high-volume gears with complex tooth profiles efficiently, while broaching is ideal for creating precise internal shapes, such as splines and keyways, with tight tolerances. Choosing the right process depends on factors like production volume, material hardness, and geometric complexity to ensure optimal performance and cost-effectiveness.

Hobbing vs broaching Infographic

libmatt.com

libmatt.com