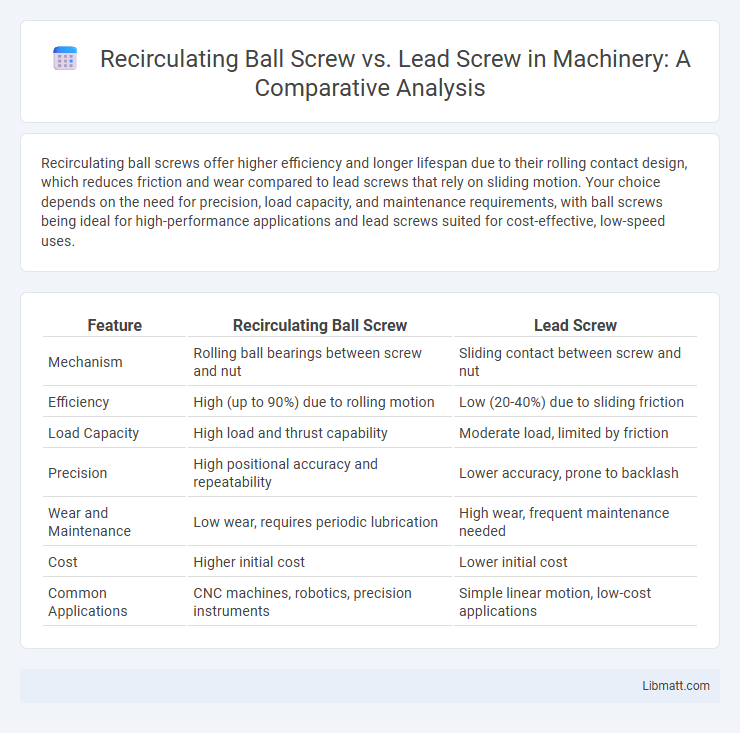

Recirculating ball screws offer higher efficiency and longer lifespan due to their rolling contact design, which reduces friction and wear compared to lead screws that rely on sliding motion. Your choice depends on the need for precision, load capacity, and maintenance requirements, with ball screws being ideal for high-performance applications and lead screws suited for cost-effective, low-speed uses.

Table of Comparison

| Feature | Recirculating Ball Screw | Lead Screw |

|---|---|---|

| Mechanism | Rolling ball bearings between screw and nut | Sliding contact between screw and nut |

| Efficiency | High (up to 90%) due to rolling motion | Low (20-40%) due to sliding friction |

| Load Capacity | High load and thrust capability | Moderate load, limited by friction |

| Precision | High positional accuracy and repeatability | Lower accuracy, prone to backlash |

| Wear and Maintenance | Low wear, requires periodic lubrication | High wear, frequent maintenance needed |

| Cost | Higher initial cost | Lower initial cost |

| Common Applications | CNC machines, robotics, precision instruments | Simple linear motion, low-cost applications |

Introduction to Recirculating Ball Screws and Lead Screws

Recirculating ball screws provide precise linear motion by converting rotary motion using ball bearings that recirculate within the screw groove, minimizing friction and enhancing efficiency. Lead screws operate through direct contact between the threaded shaft and nut, offering simpler construction but higher friction and lower efficiency compared to ball screws. Both components are fundamental in CNC machinery, robotics, and automation, with ball screws favored for high precision and lead screws chosen for cost-effective, low-speed applications.

How Recirculating Ball Screws Work

Recirculating ball screws operate by converting rotational motion into linear motion with high efficiency, using a series of ball bearings that roll between the screw shaft and the nut. This mechanism reduces friction and wear compared to lead screws, enabling smoother motion and greater load capacity. The balls recirculate through return channels within the nut, ensuring continuous contact and minimal backlash for precise positioning applications.

Understanding Lead Screw Mechanisms

Lead screw mechanisms convert rotary motion into linear motion through a threaded shaft and nut, relying on sliding contact between components, which results in higher friction and wear. Recirculating ball screws utilize ball bearings circulating within the nut to significantly reduce friction, enhancing efficiency and durability. Understanding these differences helps you choose the right mechanism for applications requiring precise positioning and long service life.

Key Differences Between Ball Screws and Lead Screws

Ball screws feature rolling ball bearings between the screw and nut, significantly reducing friction and enabling higher efficiency and precision compared to lead screws, which rely on sliding contact. Lead screws exhibit self-locking behavior, making them suitable for vertical applications without backlash but generally operate with lower efficiency and wear more quickly under heavy loads. Ball screws support higher speeds and longer service life, while lead screws offer simpler construction and cost-effectiveness for light-duty applications.

Efficiency Comparison: Ball Screw vs Lead Screw

Recirculating ball screws offer significantly higher mechanical efficiency, typically ranging from 90% to 98%, compared to lead screws, which usually achieve 20% to 50%. The reduced friction in ball screws results in less heat generation and wear, enhancing performance in high-speed and heavy-load applications. Lead screws, despite lower efficiency, provide self-locking capability, beneficial for precise positioning without back driving.

Load Capacity and Performance Analysis

Recirculating ball screws offer significantly higher load capacity and superior performance compared to lead screws due to their rolling element design, which minimizes friction and wear. Your application will benefit from the enhanced efficiency and precision of ball screws in high-load, high-speed operations, whereas lead screws are suitable for lighter loads and lower speeds with simpler maintenance. Performance analysis reveals ball screws maintain accuracy and longevity under continuous heavy loads, while lead screws may experience faster backlash and reduced lifespan under similar conditions.

Accuracy and Precision in Motion Control

Recirculating ball screws offer superior accuracy and precision in motion control due to their low friction and minimal backlash, enabling smoother and more consistent linear movement. Lead screws, while simpler and cost-effective, generally exhibit higher friction and backlash, which can reduce positional accuracy and repeatability over time. For applications demanding high precision and rigidity, recirculating ball screws are preferred for their efficient load distribution and enhanced mechanical performance.

Applications: Where to Use Ball Screws vs Lead Screws

Recirculating ball screws excel in high-precision, high-speed applications such as CNC machines, robotics, and aerospace systems due to their low friction and high efficiency. Lead screws are ideal for low-speed, high-thrust scenarios like linear actuators, clamps, or positioning devices where simplicity and cost-effectiveness matter. Understanding the specific demands of your application helps determine whether the smooth, precise motion of ball screws or the robust, self-locking feature of lead screws is the best fit.

Cost Considerations and Maintenance Requirements

Recirculating ball screws generally have higher upfront costs due to precision manufacturing and complex components, but they offer lower maintenance needs and longer service life thanks to reduced friction and efficient load distribution. Lead screws are more affordable initially, making them a cost-effective choice for low-load applications, but they require frequent maintenance such as lubrication and may experience faster wear over time. Your decision should weigh initial investment against ongoing maintenance expenses and operational durability.

Choosing the Right Screw Type for Your Application

Recirculating ball screws offer high efficiency and precision with low friction, making them ideal for applications requiring smooth, consistent motion under heavy loads. Lead screws provide simpler design and lower cost but tend to have higher friction and wear, better suited for light-duty or self-locking applications. Evaluating load capacity, accuracy, speed, and maintenance needs helps you choose the best screw type for your specific mechanical or automation project.

Recirculating ball screw vs lead screw Infographic

libmatt.com

libmatt.com