Roller chains offer high durability and are ideal for heavy-load applications, while silent chains operate more quietly and smoothly, making them suitable for reducing noise in precision machinery. Your choice depends on balancing the need for strength versus noise reduction in the specific mechanical environment.

Table of Comparison

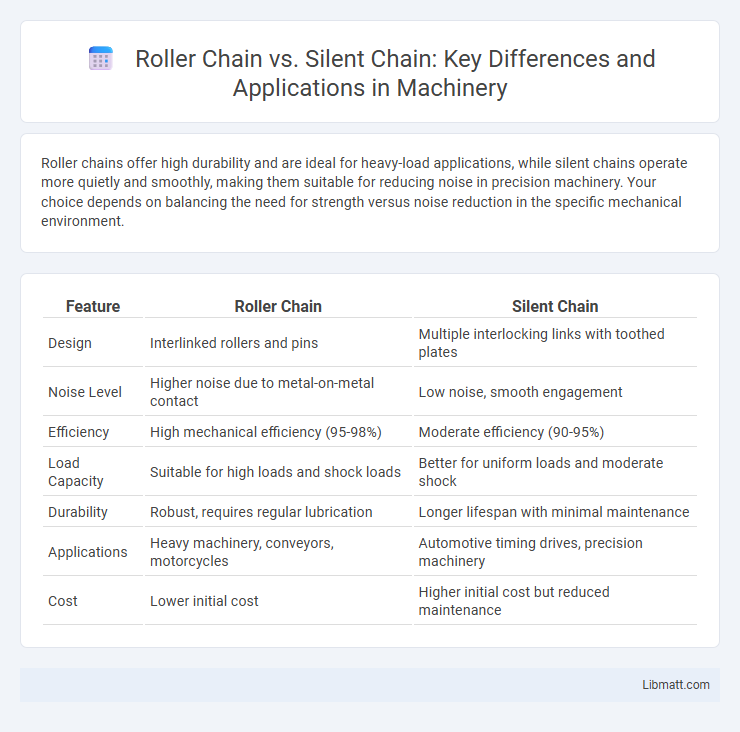

| Feature | Roller Chain | Silent Chain |

|---|---|---|

| Design | Interlinked rollers and pins | Multiple interlocking links with toothed plates |

| Noise Level | Higher noise due to metal-on-metal contact | Low noise, smooth engagement |

| Efficiency | High mechanical efficiency (95-98%) | Moderate efficiency (90-95%) |

| Load Capacity | Suitable for high loads and shock loads | Better for uniform loads and moderate shock |

| Durability | Robust, requires regular lubrication | Longer lifespan with minimal maintenance |

| Applications | Heavy machinery, conveyors, motorcycles | Automotive timing drives, precision machinery |

| Cost | Lower initial cost | Higher initial cost but reduced maintenance |

Introduction to Roller Chain and Silent Chain

Roller chains consist of a series of cylindrical rollers held together by side links, providing durability and efficient power transmission in various machinery. Silent chains feature a series of linked plates with teeth that mesh smoothly with sprockets, reducing noise and vibration during operation. Choosing between a roller chain or silent chain depends on your application's need for quiet performance versus strength and wear resistance.

Key Differences in Design and Structure

Roller chains feature interlinked metal plates connected by cylindrical rollers, which provide efficient power transmission and durability in heavy-duty applications. Silent chains consist of multiple thin metal plates linked together by pins, designed to engage sprockets more smoothly, reducing noise and vibration levels. Understanding these key differences in design and structure helps you select the optimal chain type for your machinery's performance and noise requirements.

Performance and Efficiency Comparison

Roller chains offer high tensile strength and durability, making them ideal for heavy-load applications with moderate speed. Silent chains excel in reducing noise and vibration, providing smoother and more efficient power transmission at high speeds. Your choice depends on whether maximum strength or quiet, efficient operation is the priority.

Noise Levels and Vibration Analysis

Roller chains generate higher noise levels due to metal-on-metal contact, causing significant vibration and acoustic impact during operation. Silent chains utilize interlocking links with reduced metal contact, resulting in smoother engagement and lower noise emission. Vibration analysis reveals silent chains offer enhanced damping characteristics, making them preferable for noise-sensitive applications.

Durability and Wear Resistance

Roller chains exhibit high durability due to their robust pin-and-bushing design, making them suitable for heavy-duty applications with significant torque and load. Silent chains, constructed with interlocking links and flexible plates, offer superior wear resistance and smoother operation, reducing noise and vibration in high-speed applications. Both chain types benefit from advanced materials and coatings that enhance longevity, but silent chains generally provide better performance in minimizing wear under continuous, high-speed conditions.

Maintenance Requirements

Roller chains require regular lubrication and cleaning to prevent wear and corrosion, making maintenance more frequent. Silent chains, designed with interlocking links that reduce friction, typically demand less frequent maintenance and offer longer service life. Your choice depends on balancing maintenance intervals with operational efficiency and noise reduction needs.

Typical Applications and Industries

Roller chains are commonly used in heavy machinery, automotive transmissions, and agricultural equipment due to their durability and load-bearing capacity. Silent chains typically serve in high-speed, precision applications such as automotive timing systems, printing presses, and conveyors where noise reduction and smooth operation are critical. Your choice between the two depends on whether your industry prioritizes strength and reliability or quiet, efficient performance.

Cost Considerations and Value

Roller chains typically offer a lower initial cost compared to silent chains, making them a cost-effective option for many standard applications. Silent chains provide enhanced durability and quieter operation, which can reduce long-term maintenance expenses and downtime, delivering better overall value in high-performance or noise-sensitive environments. Your choice between the two should balance upfront investment with anticipated operational efficiency and maintenance savings.

Advantages and Disadvantages

Roller chains offer high tensile strength and durability, making them ideal for heavy-duty applications, but they tend to be noisier and require regular lubrication. Silent chains provide smoother and quieter operation with reduced vibration, enhancing performance in noise-sensitive environments, yet they are typically less robust under extreme loads and can be more expensive. Choosing between roller and silent chains depends on the balance between load capacity, noise requirements, maintenance, and cost considerations in specific industrial settings.

Choosing the Right Chain for Your Application

Selecting the right chain depends on load requirements, speed, and noise considerations; roller chains excel in durability and power transmission for heavy-duty applications, while silent chains offer quieter operation and smoother performance in high-speed machinery. Roller chains provide superior tensile strength and ease of maintenance, making them ideal for conveyors and agricultural equipment. Silent chains minimize vibration and extend component life, preferred in automotive timing systems and precision industrial equipment.

Roller chain vs silent chain Infographic

libmatt.com

libmatt.com