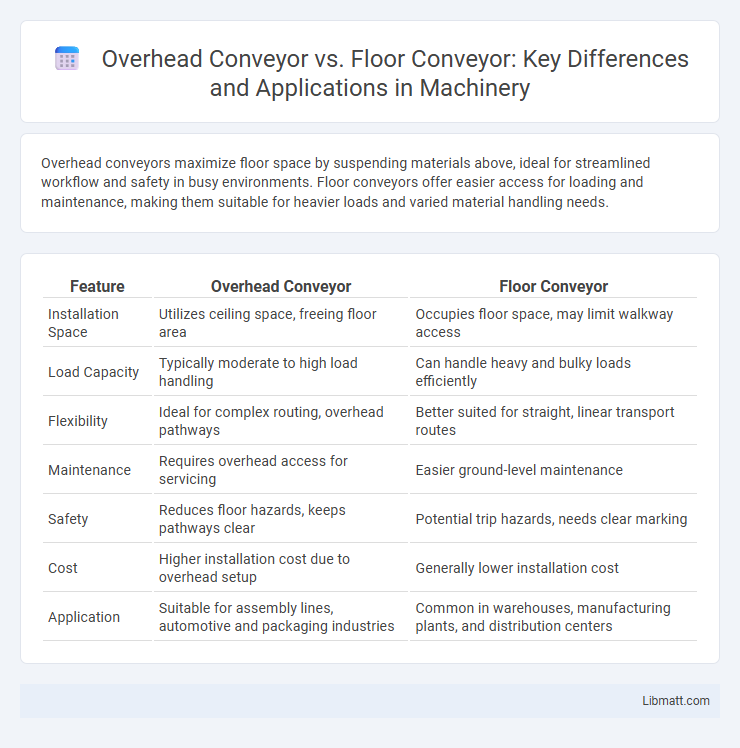

Overhead conveyors maximize floor space by suspending materials above, ideal for streamlined workflow and safety in busy environments. Floor conveyors offer easier access for loading and maintenance, making them suitable for heavier loads and varied material handling needs.

Table of Comparison

| Feature | Overhead Conveyor | Floor Conveyor |

|---|---|---|

| Installation Space | Utilizes ceiling space, freeing floor area | Occupies floor space, may limit walkway access |

| Load Capacity | Typically moderate to high load handling | Can handle heavy and bulky loads efficiently |

| Flexibility | Ideal for complex routing, overhead pathways | Better suited for straight, linear transport routes |

| Maintenance | Requires overhead access for servicing | Easier ground-level maintenance |

| Safety | Reduces floor hazards, keeps pathways clear | Potential trip hazards, needs clear marking |

| Cost | Higher installation cost due to overhead setup | Generally lower installation cost |

| Application | Suitable for assembly lines, automotive and packaging industries | Common in warehouses, manufacturing plants, and distribution centers |

Introduction to Overhead and Floor Conveyors

Overhead conveyors are ceiling-mounted systems designed to transport materials above ground, maximizing floor space and improving workflow efficiency in manufacturing and warehousing environments. Floor conveyors, positioned at ground level, are versatile solutions commonly used for moving goods along production lines or within distribution centers, offering easy access for maintenance and integration. Choosing between overhead and floor conveyors depends on space constraints, load type, and operational requirements, with overhead conveyors excelling in space-saving and floor conveyors providing straightforward installation and flexibility.

Key Differences Between Overhead and Floor Conveyors

Overhead conveyors are suspended systems ideal for saving floor space and transporting materials above production lines, while floor conveyors operate at ground level and are suited for heavier loads and easier loading or unloading. Overhead conveyors excel in complex routing and continuous flow applications, whereas floor conveyors offer greater flexibility in handling bulky or heavy items with simpler installation. The choice between overhead and floor conveyors depends on factory layout, load characteristics, and workflow efficiency requirements.

Advantages of Overhead Conveyors

Overhead conveyors offer significant space-saving advantages by utilizing ceiling space, freeing up valuable floor area for other operations. They provide efficient material handling in environments with heavy traffic or limited floor space, improving workflow and reducing bottlenecks. Your facility can benefit from enhanced safety and cleanliness since overhead conveyors keep products off the ground, minimizing contamination and damage risks.

Benefits of Floor Conveyors

Floor conveyors offer easier installation and maintenance due to their accessible positioning at ground level, reducing downtime and operational costs. Their adaptability supports a wide range of product sizes and weights, making them ideal for diverse industrial applications. You benefit from improved worker safety and easier integration with existing floor-based systems, enhancing overall workflow efficiency.

Typical Applications of Overhead Conveyors

Overhead conveyors are typically used in automotive assembly lines, garment manufacturing, and warehouses to efficiently transport heavy or bulky items above the work area, saving valuable floor space. These systems are ideal for continuous movement of parts, enabling smoother workflow and reducing bottlenecks in production environments. Your facility can benefit from overhead conveyors when handling complex processes that require freeing up ground space while maintaining high throughput.

Common Uses of Floor Conveyors

Floor conveyors are commonly used in manufacturing and distribution centers to transport heavy materials and pallets efficiently across short to medium distances. They are ideal for assembly lines, packaging processes, and loading or unloading shipping areas where stable, flat surfaces are essential. Your facility can benefit from floor conveyors when flexibility and easy access to transported goods are priorities, especially in environments with consistent floor space.

Space Utilization: Overhead vs Floor Conveyors

Overhead conveyors maximize space utilization by freeing up floor area, allowing for better movement of personnel and equipment below, making them ideal for congested workspaces. Floor conveyors occupy valuable floor space, potentially limiting layout flexibility and operational flow in confined environments. Selecting overhead or floor conveyors depends on your facility's spatial constraints and workflow requirements to ensure optimal use of available space.

Installation and Maintenance Considerations

Overhead conveyors typically require more complex installation involving ceiling reinforcements and precise alignment of support structures, while floor conveyors have simpler foundation needs and easier accessibility. Maintenance of overhead conveyors often demands specialized equipment for height access and careful handling to avoid ceiling damage, whereas floor conveyors allow straightforward inspection and repairs at ground level. Evaluating space constraints and ease of maintenance access is essential when selecting between overhead and floor conveyor systems.

Cost Comparison: Overhead vs Floor Conveyors

Overhead conveyors generally have higher upfront costs compared to floor conveyors due to increased structural support and installation requirements. Floor conveyors tend to be more cost-effective initially but may incur higher maintenance expenses due to floor space wear and potential obstruction issues. Evaluating total cost of ownership requires considering installation, maintenance, and operational efficiency differences between overhead and floor conveyor systems.

Choosing the Right Conveyor System for Your Facility

When choosing the right conveyor system for your facility, consider space availability and workflow efficiency; overhead conveyors maximize floor space by utilizing ceiling areas, ideal for facilities with limited ground space. Floor conveyors offer easier installation and maintenance, suitable for heavier loads and straightforward transport routes. Your decision should balance operational needs with facility layout to optimize productivity and safety.

Overhead conveyor vs floor conveyor Infographic

libmatt.com

libmatt.com