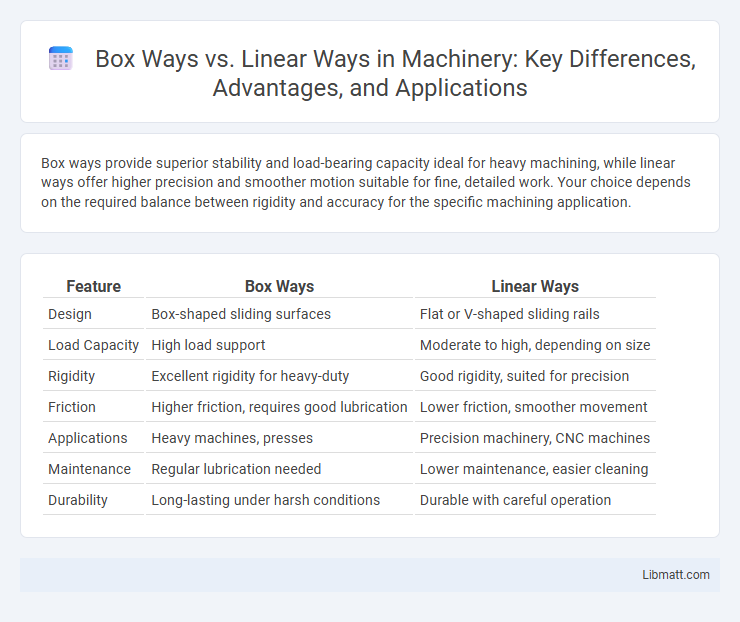

Box ways provide superior stability and load-bearing capacity ideal for heavy machining, while linear ways offer higher precision and smoother motion suitable for fine, detailed work. Your choice depends on the required balance between rigidity and accuracy for the specific machining application.

Table of Comparison

| Feature | Box Ways | Linear Ways |

|---|---|---|

| Design | Box-shaped sliding surfaces | Flat or V-shaped sliding rails |

| Load Capacity | High load support | Moderate to high, depending on size |

| Rigidity | Excellent rigidity for heavy-duty | Good rigidity, suited for precision |

| Friction | Higher friction, requires good lubrication | Lower friction, smoother movement |

| Applications | Heavy machines, presses | Precision machinery, CNC machines |

| Maintenance | Regular lubrication needed | Lower maintenance, easier cleaning |

| Durability | Long-lasting under harsh conditions | Durable with careful operation |

Introduction to Box Ways and Linear Ways

Box ways and linear ways are essential components in machine tool design, providing stability and precision for motion control. Box ways feature a robust, box-shaped cross-section that offers superior rigidity and vibration damping, ideal for heavy-duty machining applications. Linear ways, characterized by their straight, flat surfaces, deliver smooth, accurate linear motion with lower friction, making them suitable for high-speed and precision tasks where compactness is key.

Defining Box Ways: Structure and Function

Box ways are a robust guiding system in machine tools, characterized by a rectangular cross-section that provides exceptional rigidity and resistance to twisting forces. Their structure enables even distribution of load across the moving parts, enhancing precision and stability during heavy-duty machining operations. Understanding the design of box ways helps you select machinery that ensures consistent accuracy and long-lasting performance.

Understanding Linear Ways: Design and Features

Linear ways consist of precision-machined steel rails and matching blocks, designed to guide machine tool components with minimal friction and high accuracy. Their design emphasizes rigidity and smooth sliding motion, incorporating recirculating ball bearings or roller elements to achieve consistent performance. You benefit from enhanced positional accuracy and load capacity, making linear ways ideal for applications requiring precise, repeatable movements.

Historical Evolution in Machine Tool Guides

Box ways and linear ways have distinct historical roots in machine tool guide evolution, with box ways emerging during the early 20th century to provide superior rigidity and load-bearing capacity for heavy-duty machining tasks. Linear ways evolved later, incorporating precision-ground rails and recirculating ball bearings to enhance smoothness and accuracy in high-speed, light-load applications. Your choice between box and linear ways will depend on the desired balance between durability and precision in modern manufacturing environments.

Performance Comparison: Box Ways vs Linear Ways

Box ways provide enhanced rigidity and load distribution, resulting in superior vibration damping and stability during heavy-duty machining compared to linear ways. Linear ways offer higher precision and smoother motion with lower friction, making them ideal for high-speed, lightweight applications. Performance in CNC machines depends on the balance between the required load capacity, precision, and speed, with box ways excelling in durability and linear ways in accuracy and efficiency.

Accuracy and Rigidity Analysis

Box ways provide superior rigidity compared to linear ways due to their larger contact surface area and robust construction, resulting in enhanced resistance to deflection and vibration under heavy loads. This increased rigidity directly contributes to higher machining accuracy, minimizing tool deflection and improving surface finish quality. Conversely, linear ways offer less rigidity but can achieve precise linear motion with proper guidance systems, though they are generally more susceptible to deflection and wear in high-load applications.

Maintenance and Longevity Considerations

Box ways offer superior durability and reduced maintenance requirements due to their larger surface contact area and ability to handle heavier loads, resulting in extended machine longevity. Linear ways, while providing higher precision and smoother motion, often demand more frequent lubrication and maintenance to prevent wear and ensure consistent performance. Choosing the right guide system can significantly impact your machine's operational lifespan and maintenance schedule.

Cost Implications of Box Ways and Linear Ways

Box ways generally have higher initial costs due to their robust construction and increased material usage, making them ideal for heavy-duty applications requiring greater rigidity. Linear ways offer a more cost-effective solution with simplified design and manufacturing processes, reducing both upfront expenses and maintenance costs. Choosing between box ways and linear ways depends on balancing budget constraints with the required precision and load-bearing capabilities.

Applications: Best Use Cases for Each Guideway

Box ways offer superior rigidity and load-carrying capacity, making them ideal for heavy-duty machining applications such as milling and turning large workpieces. Linear ways provide high precision and smooth motion, best suited for high-speed, lightweight tasks like CNC engraving and 3D printing. Selecting the right guideway enhances Your machine's performance by aligning its design with specific operational demands.

Choosing the Right Guideway for Your CNC Machine

Choosing the right guideway for your CNC machine depends on your application's precision and load capacity requirements. Box ways provide superior rigidity and vibration dampening, making them ideal for heavy-duty machining tasks and high radial loads. Linear ways offer smoother motion and higher accuracy, perfect for precision machining where minimal friction and maintenance are essential.

Box ways vs linear ways Infographic

libmatt.com

libmatt.com