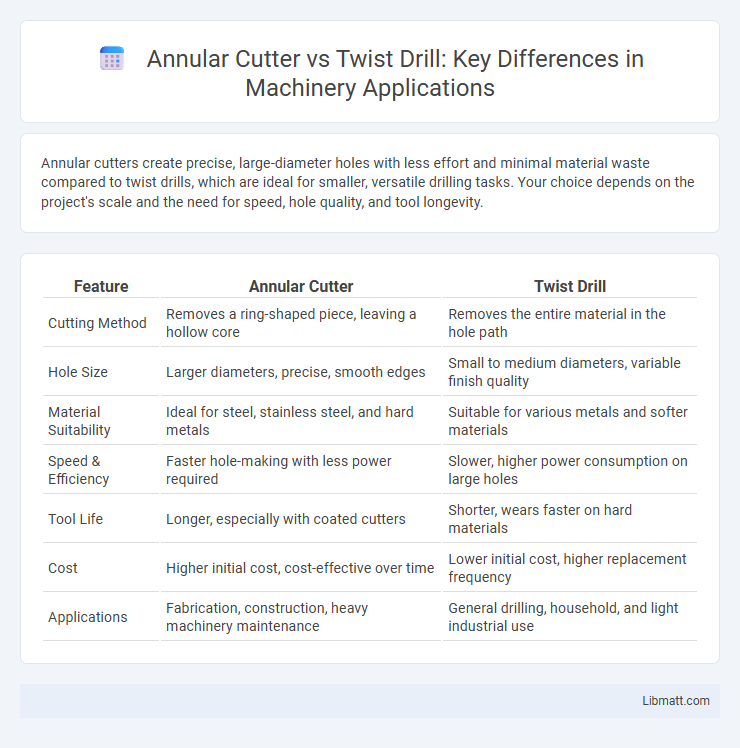

Annular cutters create precise, large-diameter holes with less effort and minimal material waste compared to twist drills, which are ideal for smaller, versatile drilling tasks. Your choice depends on the project's scale and the need for speed, hole quality, and tool longevity.

Table of Comparison

| Feature | Annular Cutter | Twist Drill |

|---|---|---|

| Cutting Method | Removes a ring-shaped piece, leaving a hollow core | Removes the entire material in the hole path |

| Hole Size | Larger diameters, precise, smooth edges | Small to medium diameters, variable finish quality |

| Material Suitability | Ideal for steel, stainless steel, and hard metals | Suitable for various metals and softer materials |

| Speed & Efficiency | Faster hole-making with less power required | Slower, higher power consumption on large holes |

| Tool Life | Longer, especially with coated cutters | Shorter, wears faster on hard materials |

| Cost | Higher initial cost, cost-effective over time | Lower initial cost, higher replacement frequency |

| Applications | Fabrication, construction, heavy machinery maintenance | General drilling, household, and light industrial use |

Introduction to Annular Cutters and Twist Drills

Annular cutters, designed for efficient metal hole cutting, create precise, large-diameter holes by removing only the material at the periphery, reducing cutting time and effort compared to traditional bits. Twist drills, widely used for general-purpose drilling, feature a helical flute design that removes chips through the center of the bit, suitable for a variety of materials but often slower and less precise in large-diameter applications. The choice between an annular cutter and a twist drill depends on factors such as hole size, material type, drilling speed, and desired finish quality.

What Is an Annular Cutter?

An annular cutter is a specialized cutting tool designed for creating precise, large-diameter holes by removing only the material around the hole's perimeter, unlike a twist drill that removes the entire hole volume. Your drilling projects benefit from an annular cutter's efficiency and reduced power consumption, making it ideal for metalworking and structural applications. This tool's design also minimizes heat generation and extends tool life compared to traditional twist drills.

What Is a Twist Drill?

A twist drill is a cutting tool commonly used to create cylindrical holes in various materials by rotating its helical flutes to remove debris from the hole. Compared to an annular cutter, a twist drill typically removes the entire material within the hole, resulting in slower cutting and more effort. Your choice between the two depends on the speed, precision, and material removal efficiency required for your drilling task.

Key Differences Between Annular Cutters and Twist Drills

Annular cutters remove only the outer layer of material to create a hole, resulting in faster, cleaner cuts with less power consumption compared to twist drills, which cut through the entire material diameter. Twist drills are versatile for a wide range of materials but tend to produce more heat, require higher torque, and generate more waste due to their full-diameter cutting action. Your choice between these tools depends on the speed, precision, and material removal efficiency needed for your drilling application.

Cutting Efficiency: Annular Cutter vs Twist Drill

Annular cutters provide superior cutting efficiency compared to twist drills by removing only the material around the hole's perimeter, resulting in faster drilling and less effort. Twist drills cut the entire hole diameter, generating more heat and requiring more power, especially in thicker materials. Your choice of cutter significantly impacts machining speed and energy consumption during metalworking tasks.

Hole Quality: Accuracy and Finish Comparison

Annular cutters produce holes with superior accuracy and a cleaner finish compared to twist drills due to their design, which removes material only around the hole's perimeter, minimizing burrs and heat buildup. Twist drills often cause more material deformation and rougher edges, requiring additional finishing work. Your choice of an annular cutter can enhance hole quality, saving time and improving precision in metalworking projects.

Material Compatibility and Applications

Annular cutters excel in cutting through tough materials such as stainless steel, cast iron, and various alloys by efficiently removing only the material around the hole's perimeter, making them ideal for heavy-duty applications like structural steel fabrication and pipe installation. Twist drills perform well on softer metals, plastics, and wood, offering versatility for general-purpose drilling but often requiring more effort and time when penetrating harder materials. Your choice between an annular cutter and a twist drill should consider the specific material hardness and application demands to ensure optimal performance and tool longevity.

Speed, Feed, and Performance Factors

Annular cutters deliver faster cutting speeds and higher feed rates compared to twist drills, significantly reducing drilling time in metalworking applications. Their design removes only the material from the hole's perimeter, enhancing cutting efficiency and minimizing power consumption, which improves overall performance and tool life. Your choice of tool will impact machining precision, surface finish, and operational efficiency based on material hardness and hole diameter requirements.

Cost Considerations: Which Tool Is More Economical?

Annular cutters generally offer higher upfront costs compared to twist drills but provide greater efficiency by removing only the material around the hole perimeter, reducing machining time and wear. Twist drills are more economical for low-volume or occasional use due to their lower purchase price, though they may wear out faster and require more power for larger holes. Your choice depends on the balance between initial investment and long-term productivity, especially in repetitive drilling tasks.

Choosing the Right Tool for Your Project

Selecting between an annular cutter and twist drill depends on the specific project requirements such as hole size, speed, and material type. Annular cutters excel in creating larger, precise holes quickly in metal, reducing cutting time and improving finish quality. Twist drills are versatile for smaller holes and general-purpose drilling, offering affordability and ease of use for a wide range of materials.

Annular cutter vs twist drill Infographic

libmatt.com

libmatt.com