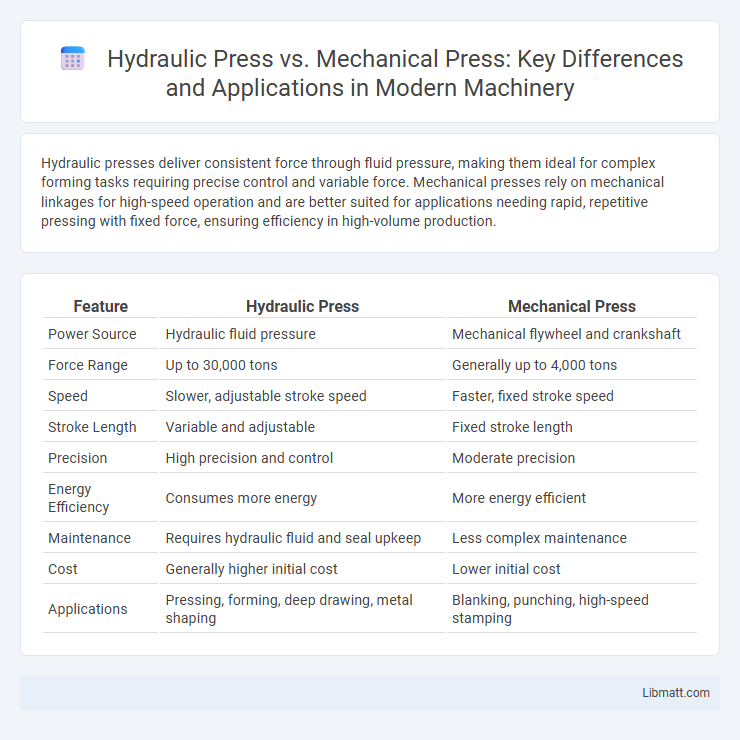

Hydraulic presses deliver consistent force through fluid pressure, making them ideal for complex forming tasks requiring precise control and variable force. Mechanical presses rely on mechanical linkages for high-speed operation and are better suited for applications needing rapid, repetitive pressing with fixed force, ensuring efficiency in high-volume production.

Table of Comparison

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Power Source | Hydraulic fluid pressure | Mechanical flywheel and crankshaft |

| Force Range | Up to 30,000 tons | Generally up to 4,000 tons |

| Speed | Slower, adjustable stroke speed | Faster, fixed stroke speed |

| Stroke Length | Variable and adjustable | Fixed stroke length |

| Precision | High precision and control | Moderate precision |

| Energy Efficiency | Consumes more energy | More energy efficient |

| Maintenance | Requires hydraulic fluid and seal upkeep | Less complex maintenance |

| Cost | Generally higher initial cost | Lower initial cost |

| Applications | Pressing, forming, deep drawing, metal shaping | Blanking, punching, high-speed stamping |

Introduction to Hydraulic and Mechanical Presses

Hydraulic presses use fluid pressure to generate a controlled and adjustable force, ideal for applications requiring precise pressure and slower operation speeds. Mechanical presses rely on mechanical linkages and flywheels to deliver rapid, repetitive strikes, making them suitable for high-speed stamping and forming tasks. The choice between hydraulic and mechanical presses depends on factors such as force control, speed, and specific manufacturing requirements.

Working Principles of Hydraulic Presses

Hydraulic presses utilize Pascal's principle, where fluid pressure is transmitted evenly through an incompressible liquid to generate high force with minimal input effort, enabling precise control of the pressing operation. Their working mechanism involves a hydraulic cylinder filled with oil that moves a piston to exert force on the workpiece, allowing for variable pressure and stroke length. This principle contrasts with mechanical presses, which rely on mechanical linkages and cams for fixed force and limited adjustability.

How Mechanical Presses Operate

Mechanical presses operate by using a motor-driven flywheel to store energy, which is then rapidly released through a crankshaft to move the ram downward with precise force and speed. This mechanism allows for consistent pressing actions ideal for high-speed stamping, forming, and punching tasks in manufacturing. Mechanical presses excel in applications requiring high repeatability and fast cycle times but may lack the adjustable force control available in hydraulic presses.

Force and Pressure Comparison

Hydraulic presses generate force through fluid pressure, allowing precise control and consistent application of high force over a longer stroke, often reaching up to 30,000 tons or more. Mechanical presses rely on mechanical energy stored in a flywheel, delivering force with high speed and repeatability, typically up to 5,000 tons, but with less pressure control than hydraulic systems. Your choice between the two depends on whether you need variable force and pressure control or rapid, consistent strokes for your manufacturing process.

Speed and Efficiency Differences

Hydraulic presses operate at variable speeds and provide consistent force throughout the stroke, making them highly efficient for tasks requiring precision and slower, controlled movements. Mechanical presses deliver faster cycle times due to their fixed speeds and rapid ram return, ideal for high-volume production where speed is critical. Your choice depends on balancing the need for speed with the efficiency of force application in your specific manufacturing process.

Application Suitability and Versatility

Hydraulic presses excel in applications requiring variable force and precise control, making them ideal for deep drawing, forming, and molding diverse materials. Mechanical presses offer high-speed, repetitive operations suited for stamping, punching, and blanking tasks in mass production environments. The versatility of hydraulic presses allows for processing thicker, more complex components, while mechanical presses are preferable for high-volume, uniform part manufacturing.

Maintenance and Lifespan Considerations

Hydraulic presses typically require more frequent maintenance due to their complex fluid systems, including regular inspections of seals, hoses, and hydraulic fluid levels to prevent leaks and ensure optimal performance. Mechanical presses generally offer a longer lifespan with lower maintenance demands since their simpler mechanical components experience less wear and are easier to service. Choosing between the two should consider your operational needs, as hydraulic presses provide versatile force control but may incur higher upkeep costs, while mechanical presses offer durability and reduced downtime over extended use.

Safety Features and Concerns

Hydraulic presses offer advanced safety features such as adjustable pressure limits and automatic overload protection, reducing the risk of operator injury. Mechanical presses, while robust, often require additional safety guards and regular maintenance to prevent accidents due to their high-speed operation. Ensuring your workplace compliance involves assessing the specific safety mechanisms integrated into the chosen press type.

Cost Analysis: Initial and Operational Expenses

Hydraulic presses generally involve higher initial costs due to complex components and advanced control systems, whereas mechanical presses offer lower upfront investment with simpler design and construction. Operational expenses for hydraulic presses include greater energy consumption and maintenance of hydraulic fluids and seals, contrasted by mechanical presses' lower energy usage but increased wear on mechanical parts requiring periodic replacements. Overall, choosing between hydraulic and mechanical presses depends on balancing initial capital with long-term operational costs tailored to specific production needs.

Choosing the Right Press for Your Needs

When selecting between a hydraulic press and a mechanical press, consider the precision and force required for your applications; hydraulic presses offer variable speed and consistent pressure ideal for complex forming tasks, while mechanical presses excel in high-speed, repetitive stamping operations. Your production volume and material type influence the decision, as hydraulic presses provide more flexibility for diverse materials, whereas mechanical presses are optimized for efficiency in mass production. Evaluating cycle time, maintenance costs, and operational control ensures you choose the right press tailored to your manufacturing needs.

Hydraulic press vs mechanical press Infographic

libmatt.com

libmatt.com